Are you tired of your Stihl pole saw not working at its full potential? Maybe it’s time to adjust the carburetor. This small but vital component is responsible for the fuel and air mixture that powers your saw. If it’s not set correctly, your saw could have trouble starting, run poorly, or even overheat.

But don’t worry, adjusting the carburetor on your Stihl pole saw is a relatively simple process that can be done in just a few steps. Whether you’re a seasoned pro or just getting started, this guide will walk you through the process of fine-tuning your carburetor to ensure optimal performance. Think of it like tuning an instrument – you want everything to be in harmony so your saw will sing.

And with the right adjustments, your Stihl pole saw will be cutting through branches like a hot knife through butter in no time. So grab your tools, let’s dive in, and get your Stihl pole saw running like a top.

Overview of Carburetor Adjustment

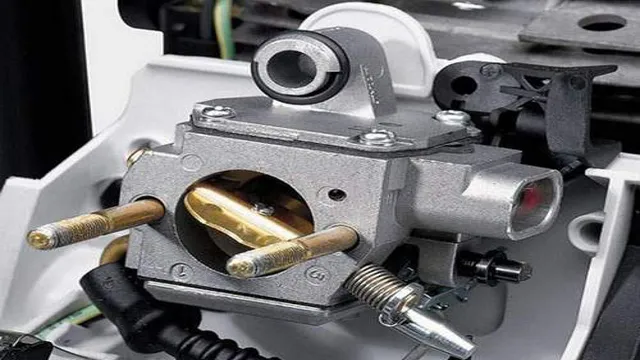

If you’re wondering how to adjust the carburetor on your Stihl pole saw, then you’re in luck! Proper carburetor adjustment is essential for your saw to perform optimally. First, make sure the air filter is clean and free of debris. Then locate the three adjustment screws on the carburetor: the idle screw, low-speed screw, and high-speed screw.

Mark their positions before making any changes. To adjust the idle, turn the screw until the chain stops moving. For the low-speed screw, turn it clockwise until the engine begins to slow down, then counterclockwise until it speeds up.

Finally, adjust the high-speed screw until the engine reaches its peak RPM. Repeat the process until the saw runs smoothly without stalling or overheating. Keep in mind that improper adjustments can cause damage to your saw, so if you’re unsure, consult a professional.

Understanding the Carburetor

Carburetor Adjustment If you’re a car enthusiast, then you’re probably familiar with the carburetor. It’s a component of your engine that mixes fuel and air to create combustion. Over time, your carburetor may need to be adjusted in order to maintain peak performance.

Carburetor adjustments are generally made by adjusting the screws on the carburetor. These screws control the amount of fuel and air that enter the engine. If you’re experiencing issues with your car’s performance, it’s possible that your carburetor is out of adjustment.

Adjusting your carburetor may help to improve your car’s acceleration and overall performance. However, it’s important to remember that carburetor adjustments should only be attempted by someone with experience working on engines. If you’re not comfortable making adjustments to your carburetor, it’s best to leave it up to a professional.

Tools Required for Adjustment

When it comes to adjusting a carburetor, having the right tools makes all the difference. Some of the essential tools you’ll need include screwdrivers of varying sizes, a carburetor adjustment tool, a vacuum gauge, and a spark plug wrench. These tools help you adjust the air-fuel mixture and idle speed of the engine, ensuring optimal performance and efficiency.

Using the screwdrivers, you can adjust the air and fuel screws, whereas the carburetor adjustment tool simplifies the process of adjusting the idle speed. The vacuum gauge is also crucial as it helps you measure the amount of vacuum pressure produced by the engine, which affects the carburetor’s operation. Finally, a spark plug wrench allows you to remove and inspect the spark plugs, which can indicate issues with the carburetor’s performance.

By having these tools at your disposal, you can easily fine-tune your carburetor and achieve optimal performance from your engine.

Preparations Before Adjustment

Adjusting the carburetor on your Stihl pole saw is a crucial part of maintaining its efficiency and performance. However, before you start adjusting the carburetor, there are a few necessary preparations you must undertake. Firstly, check the air filter and clean it if it’s dirty or clogged.

Clogged air filters restrict air intake, which affects engine performance. Next, check the fuel filter and replace it if it’s damaged. A damaged fuel filter can cause fuel flow issues, which may cause the engine to stall or run irregularly.

Moreover, ensure that the fuel mixture in the tank is fresh and mixed correctly. Old gas or an incorrect fuel mixture can affect the engine’s combustion and affect its performance. Lastly, inspect the spark plug and ensure that it’s clean and not damaged.

A dirty or damaged spark plug can cause a weak spark, leading to engine stalling or irregular performance. By following these simple preparations, you can maintain your Stihl pole saw’s efficiency and ensure optimal performance after adjusting the carburetor.

Check Air Filter

Before you start adjusting your car’s performance, it’s important to make sure that your air filter is clean and functioning properly. A dirty air filter can severely hinder your car’s performance by restricting airflow to your engine, which can lead to decreased fuel efficiency and power. To check your air filter, you’ll want to pop the hood and locate the air filter housing.

The air filter should be easily accessible and visible as soon as you remove the housing cover. Once you have located the filter, inspect it for any dirt or debris that may have accumulated. You can tap it gently to dislodge any loose dirt or debris, but if the filter is heavily soiled, it’s best to replace it altogether.

By ensuring that your air filter is clean and well-maintained, you set a sturdy foundation for optimal engine performance.

Check Fuel Filter and Lines

When it comes to checking your fuel filter and lines, there are a few things you should do to prepare for the task. Firstly, make sure that you’ve gathered all of the necessary tools and equipment, including a wrench, pliers, and safety glasses. It’s also a good idea to consult your vehicle’s owner manual to ensure that you’re clear on the location and type of fuel filter and lines in your specific make and model.

Before starting any work, ensure that your vehicle is parked on level ground and that the engine is off. You should also take some precautions to prevent fuel from leaking or igniting. This includes disconnecting the battery, relieving fuel pressure from the system, and placing rags or a catch basin under the filter and lines.

Once you’ve taken these preparation steps, it’s time to begin the actual inspection of the fuel filter and lines. Start by inspecting the outside of the fuel filter for any signs of damage or corrosion, and then move on to the fuel lines, looking for cracks, leaks, or other damage. If any issues are found, it’s time to replace or repair the damaged part.

In conclusion, checking your fuel filter and lines is an essential part of maintaining your vehicle’s performance and reliability. By following the proper steps for preparing and inspecting them, you can ensure that your fuel system is in top condition and avoid costly repairs down the road.

Warm Up the Saw

Before making any adjustments to your saw, it’s important to properly warm it up. This will not only prevent any potential damage to the saw, but also ensure that it is running efficiently and effectively. Start by checking for any debris or buildup on the blade and removing it with a stiff brush.

Next, check that all the components are properly tightened and secured. Then, turn on the saw and let it run for a few minutes before beginning any work. During this time, listen for any unusual noises or vibrations that may indicate a problem with the saw.

By taking the time to properly warm up your saw, you can ensure that it is ready to tackle any job you have in store for it.

Adjusting the Carburetor

Adjusting the carburetor on a Stihl pole saw is an essential maintenance task that ensures smooth and efficient operation. Start by locating the carburetor adjustment screws, which are usually located on the side of the carburetor. In most cases, there are three screws: the low-speed screw, the high-speed screw, and the idle-speed screw.

Before adjusting any of these screws, make sure the saw is turned off and cooled down. Then, turn the low-speed screw clockwise until it stops and then 1/4 turn counterclockwise. Do the same for the high-speed screw, turning it clockwise until it stops, and then 1/4 turn counterclockwise.

Lastly, adjust the idle-speed screw to achieve the desired idle speed. Once all of the screws have been adjusted, test the saw to ensure it is running smoothly. If it’s still not performing well, you may need to consult a professional to make further adjustments.

Locate the Carburetor Screws

When it comes to adjusting the carburetor, it all starts with locating the carburetor screws. These screws are crucial to the proper functioning of the carburetor and any adjustments made to them can have a significant impact on the performance of your vehicle. So, it’s important to know where they are and what they do.

Typically found at the bottom of the carburetor, there are usually two screws – one for the idle speed and another for the air fuel mixture. The idle speed screw is responsible for adjusting the speed at which the engine idles, while the air fuel mixture screw is responsible for adjusting the ratio of air to fuel in the mixture that enters the engine. These screws can be easily adjusted with the right tools and a little bit of know-how.

But it’s important to remember that making adjustments to the carburetor should only be done by those who know what they are doing, as improper adjustments can lead to engine damage or poor performance. So, if you’re not confident in your ability to adjust the carburetor, it’s best to leave it to the professionals.

Turning the Idle Speed Screw

Adjusting the carburetor of your engine can greatly influence its performance. One crucial step in this process is turning the idle speed screw. This screw controls the idle speed of your engine, which is the rpm at which it runs while at a standstill.

If the idle speed is too high, your engine may suck in too much air and fuel, leading to irregular idle, stalling, and increased emissions. On the other hand, if the idle speed is too low, your engine may struggle to keep running, producing a rough idle and causing stalling. To adjust the idle speed screw, start by locating it on your carburetor.

You may find it on the throttle plate or near the base of the carburetor. Turn the screw clockwise to increase the idle speed and counterclockwise to decrease it. Use a tachometer to determine the correct idle speed for your engine.

Make sure to adjust the screw gently and in small increments until you reach the desired speed. Remember, turning the screw too far can have adverse effects on your engine’s performance, so take it slow and steady. In conclusion, adjusting the idle speed screw is an essential step in fine-tuning your engine’s carburetor.

It requires careful and precise adjustments to achieve the optimal idle speed and ensure that your engine runs smoothly and efficiently. By taking the time to adjust this screw properly, you can improve your engine’s fuel efficiency, reduce emissions, and prolong its lifespan, saving you time and money in the long run.

Turning the Low Speed Mixture Screw

Adjusting the Carburetor by Turning the Low Speed Mixture Screw If you’re experiencing problems with the performance of your engine, it may be time to adjust the carburetor. One specific adjustment that can make a big difference is turning the low speed mixture screw. This screw controls the amount of fuel that enters the engine at low speeds.

A misadjusted screw can cause stalling, rough idling, or poor acceleration. By making small adjustments and monitoring the engine’s response, you can find the optimal setting for your carburetor. It’s important to use a small screwdriver and make very small changes at a time, as each adjustment will have an impact on the engine’s operation.

Once you’ve found the ideal setting, your engine will be running smoothly and efficiently. So, take the time to adjust the carburetor and improve the performance of your engine today!

Turning the High Speed Mixture Screw

If you’re having trouble with your carburetor and the engine isn’t running smoothly, you might need to adjust the high speed mixture screw. This screw controls the amount of fuel that’s mixed with air in the carburetor, and tweaking it can make a big difference in how your engine performs. First, you’ll need to locate the screw, which is usually located on the bottom of the carburetor or near the air filter.

Use a flathead screwdriver to turn the screw clockwise or counterclockwise, depending on your needs. If the engine is running too lean, which means it’s not getting enough fuel, turn the screw clockwise to increase the fuel flow. If it’s running too rich, which means it’s getting too much fuel, turn the screw counterclockwise to decrease the fuel flow.

It’s important to make small adjustments and test the engine after each one to find the perfect balance. With a bit of patience and experimentation, you can get your engine running like new again.

Testing the Adjustment

If you’re experiencing difficulty with your Stihl pole saw, you may need to adjust the carburetor. To do this, you will need to first locate the carburetor and air filter. Start by removing the cover of the air filter, cleaning it, and inspecting it for any damage.

Next, locate the carburetor screws. The first screw is the idle screw, which controls the idle speed when the saw is running. The second screw is the high-speed screw, which adjusts the fuel mixture at high speeds.

Turn the idle screw clockwise to increase the idle speed and counterclockwise to decrease it. To adjust the high-speed screw, start the saw and let it run at full throttle. Turn the screw clockwise until the engine begins to sputter, then turn it counterclockwise until it smooths out.

Repeat this process until the engine runs smoothly at full throttle. Remember to only make small adjustments and test the saw after each adjustment.

Performing a Spark Plug Test

When it comes to maintaining your car’s performance, spark plugs are an essential component that should not be overlooked. A simple spark plug test can determine if the adjustment is proper. This involves removing the spark plug and checking the gap between the electrodes using a spark plug gapping tool.

The measurement should meet the manufacturer’s specifications. If it is too small or too large, the adjustment must be made by bending the ground electrode. To ensure the most accurate reading, it’s essential to perform the test on a cold engine and to remove one spark plug at a time.

Neglecting a proper spark plug check could lead to your car not starting or running poorly. By testing the adjustment of the spark plugs, you can ensure that your car’s engine is running correctly and efficiently.

Performing a Cutting Test

When it comes to woodworking, performing a cutting test is an essential part of ensuring the accuracy and precision of your tools. A cutting test involves making small cuts in a piece of scrap wood to test the blade’s sharpness and to see how well it’s adjusted. You can test a variety of different settings, such as the depth of cut or the angle of the blade, to see if it will meet your needs.

It’s not enough to test the blade once and assume that it will perform the same way every time. You will need to perform cutting tests regularly and make adjustments to get the best results. For example, to test the blade’s sharpness, you can try cutting through a piece of paper or cardboard.

This will give you a good idea of how well it will perform when cutting through wood. Taking the time to perform cutting tests will help you get the most out of your tools and ensure the best quality of your work.

Conclusion

In the magical world of yard work, the Stihl pole saw stands tall as a beacon of hope for all those tangled in the branches of life. But as any seasoned sawman (or woman!) knows, the carburetor is the heart of the machine. Lucky for us, adjusting it doesn’t require a degree in sorcery.

With a few simple steps and a bit of know-how, you can fine-tune your Stihl pole saw to purr like a kitten and tackle those towering trees with ease. So grab your tools, take a deep breath, and enter the carburetor calibration zone. Your pole saw (and your pruned plants) will thank you.

“

FAQs

What are the symptoms of a poorly adjusted carburetor on a Stihl pole saw?

A poorly adjusted carburetor can lead to issues such as rough idling, difficulty starting, and decreased power and performance.

How often should the carburetor on a Stihl pole saw be adjusted?

The carburetor should be checked and adjusted as needed on a regular basis, typically every 50-60 hours of use.

Can I adjust the carburetor on my Stihl pole saw myself, or should I take it to a professional?

With the proper tools and knowledge, it is possible to adjust the carburetor yourself. However, if you are not confident in your abilities, it may be best to take it to a professional.

What tools do I need to adjust the carburetor on my Stihl pole saw?

You will typically need a screwdriver, carburetor adjustment tool, and possibly a tachometer to properly adjust the carburetor.

What is the optimal fuel mixture for a Stihl pole saw with a carburetor adjustment?

The optimal fuel mixture should be 50:1 of gasoline to oil.

What are the potential risks of improperly adjusting the carburetor on a Stihl pole saw?

Improperly adjusting the carburetor can lead to damage to the engine, decreased performance, and potentially dangerous working conditions.

How can I tell if the carburetor on my Stihl pole saw needs adjusting?

Signs that the carburetor needs adjusting include difficulty starting, rough idling, decreased performance, and excessive fuel consumption.