How The Manhattan Heavy Duty Drill Press Works: An In-Depth Guide

Have you ever come across a project that required you to drill through tough materials like metal or hardwood? If so, you understand the importance of high-precision tools that get the job done right. This is where the Manhattan Heavy Duty Drill Press comes in. This robust machine comes equipped with everything you need to take on challenging drilling projects with ease.

But how does it work, you may ask? It’s simple: the Manhattan Heavy Duty Drill Press features a powerful motor that drives a spindle to rotate and lower a drill bit onto your workpiece. The result? Smooth, clean, and accurate drilling every time. Not only is this drill press powerful and precise, but it’s also highly versatile.

With adjustable speeds, you can customize the machine to suit the demands of your project. Plus, the adjustable depth stop allows you to make consistent, repeatable holes in the same location, making it the perfect tool for production work. To top it all off, the Manhattan Heavy Duty Drill Press is built to last.

Made from high-quality, durable materials, this machine is designed to withstand the rigors of heavy use. It’s perfect for professionals and DIY enthusiasts alike, who demand the very best in their tools. So next time you find yourself faced with a tough drilling project, remember that the Manhattan Heavy Duty Drill Press is there to help you get the job done right.

Overview

If you’re looking for a powerful tool that can handle heavy-duty drilling, the Manhattan Heavy Duty Drill Press is a great option. This machine operates by using a motor to power a drill bit that can bore holes into various materials with precision and speed. The user simply selects the appropriate bit size and drilling speed before lowering the bit into the workpiece.

The drill press also includes multiple safety features such as an emergency stop button and a transparent safety guard to prevent accidents. Its durable construction and adjustable settings make it a reliable tool for both professional and DIY applications. With the Manhattan Heavy Duty Drill Press, you can tackle your toughest drilling projects with ease.

Parts of the Drill Press

The drill press is a powerful tool that helps bore holes into different materials with precision and accuracy. It has several key components that make it effective at its job. Let’s take a look at some of the parts that make up a drill press.

First, there is the base which provides stability and support for the whole machine. Attached to the base is the column, a long vertical shaft that holds the head. The head includes several parts such as the motor, spindle, and chuck.

The motor provides the power needed to spin the drill bit, while the spindle holds the bit in place, and the chuck is used to secure the drill bit. The drill press also has a table for the material being worked on to rest on. The table can be adjusted vertically and horizontally to make it easier to position the material for drilling.

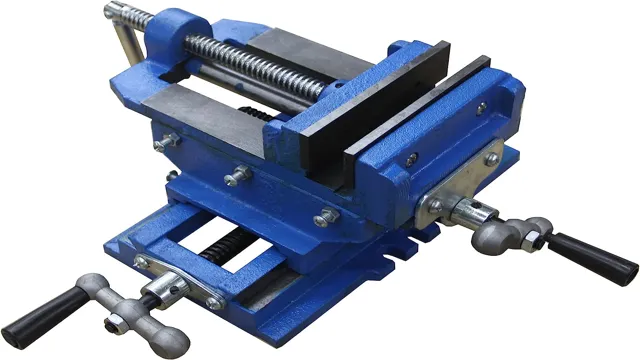

Finally, there is the drill press vise, a clamping device that holds the material securely in place during drilling. Overall, understanding the different parts of a drill press is essential for using the machine safely and effectively. With proper use, a drill press can make quick work of drilling holes in a variety of materials.

Power Source

When it comes to powering electronics, there are a multitude of options available. From traditional batteries to renewable options like solar panels and wind turbines, each power source has its own unique set of advantages and disadvantages. Traditional batteries are portable and easy to replace, but they rely on non-renewable resources and can be costly to replace frequently.

Solar panels and wind turbines are eco-friendly and cost-effective in the long run, but require larger up-front investments and may not be practical for all situations. Ultimately, choosing the right power source comes down to evaluating your individual needs and priorities. Whether you prioritize cost-effectiveness, portability, sustainability, or a combination of factors, there is a power source out there that will meet your needs.

Setting up the Drill Press

If you are wondering how the Manhattan Heavy Duty Drill Press works, then you’ve come to the right place. Setting up a drill press can be overwhelming, especially if you are new to using one. The Manhattan Heavy Duty Drill Press is a versatile tool that can be used for a variety of applications, from drilling holes in metal to woodworking.

To set it up, you’ll need to start by ensuring that your workspace is clear and well-lit. Once you have set up the drill press, make sure to adjust the table to the right height and angle. The drill press also comes with a range of speed settings to choose from, so be sure to pick the appropriate setting for your project.

With a little practice, you will be able to master the use of the Manhattan Heavy Duty Drill Press in no time. So go ahead and put it to the test – you won’t be disappointed!

Preparing the Workspace

Setting up your drill press is an essential part of preparing your workspace. First, ensure that your drill press is on a stable surface and that it is properly secured to prevent any wobbling during use. Next, make sure that all safety features are in place, such as the safety switch and the guard.

Once your drill press is securely set up, you can adjust the height and angle of the drill bit to suit your needs. It’s important to take your time with these adjustments to ensure that your drill bit is set up correctly, as it will affect the precision of your drilling. By properly setting up your drill press, you’ll be able to work safely and accurately, ensuring that your drilling projects are successful.

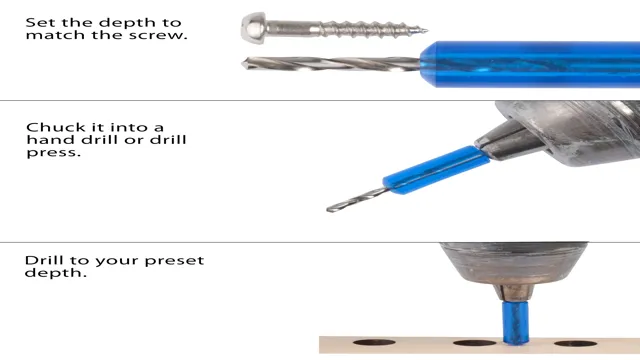

Adjusting the Drill Bit

When setting up the drill press, it’s important to know how to adjust the drill bit. First, make sure the chuck is tightened securely around the bit to prevent any wobbling or movement while drilling. Then, adjust the height of the table or platform to ensure the drill bit is perpendicular to the work surface.

This will prevent the bit from veering off course and creating a crooked hole. Finally, adjust the speed and power of the drill press according to the material you’re drilling into – slower speeds are better for harder materials while faster speeds are better for softer materials. Overall, taking the time to properly set up and adjust the drill bit will lead to more accurate and efficient drilling.

Safety Precautions

When it comes to setting up a drill press, there are a few essential safety precautions that you need to take. First and foremost, you need to ensure that the drill press is positioned on a stable surface. This will prevent it from shaking or moving while in use, and reduce the risk of injury.

Additionally, you should always wear protective eye gear and clothing when operating a drill press, as metal shards and debris can fly off the machine during use. It’s also important to ensure that the workpiece is secure, as a loose or unstable piece can cause the drill bit to break or jam, leading to potential injury. By taking these simple safety precautions, you’ll be able to operate your drill press with confidence and minimize any potential risks.

Using the Manhattan Heavy Duty Drill Press

The Manhattan Heavy Duty Drill Press is a powerful and versatile tool for any workshop or DIY project. It’s a sturdy machine that can handle almost any drilling task with ease. To use the Manhattan Heavy Duty Drill Press, you need to start by securing your workpiece to the drill press table using clamps or a vice.

Adjust the depth, speed, and angle of the drill bit to match your needs, and then lower the drill bit to the desired depth. Once you’re ready, turn on the machine and start drilling, ensuring that you maintain proper posture and control the drill firmly. With its powerful motor and precise drilling capabilities, the Manhattan Heavy Duty Drill Press is the ideal choice for any heavy-duty drilling task.

Inserting the Material to Be Drilled

When it comes to drilling, inserting the material is a crucial step, and using the Manhattan Heavy Duty Drill Press can make the process much easier. First, it’s important to secure your material in place, ensuring it won’t move or shift during the drilling process. Next, set the drill bit in the chuck and tighten it securely.

Depending on the thickness of your material, you may need to adjust the speed of the drill. Once everything is in place, slowly lower the chuck towards the material and begin drilling. Remember to wear safety glasses and take breaks as needed to prevent overheating.

With the Manhattan Heavy Duty Drill Press, you can achieve precise and accurate results with ease.

Adjusting the Depth Stop

When it comes to precision drilling, it’s crucial to ensure that your drill bit is set at the right depth. This is where adjusting the depth stop comes in handy. If you’re using the Manhattan Heavy Duty Drill Press, it’s a simple process that you can do in just a few steps.

First, locate the depth stop rod, which is typically situated on the left-hand side of the drill press. Next, rotate the depth stop collar until it’s in line with the desired drilling depth. Once you’ve done that, you can proceed to lock the collar in place using the locking screw.

With that done, you can test the drill’s depth stop by lowering the drill bit and measuring the depth of the hole. If it’s too deep or not deep enough, you can adjust the collar accordingly and repeat the process until you achieve the desired depth. With the Manhattan Heavy Duty Drill Press, adjusting the depth stop is a breeze, ensuring accurate drilling with every use.

Adjusting the Table and Fence

Adjusting the Table and Fence on the Manhattan Heavy Duty Drill Press can be a bit confusing at first, but with a little practice and patience, anyone can master it. The first step is to ensure that the drill press is correctly anchored to the workbench. Once this is done, the operator can adjust the table and fence to suit the project they are working on.

The table can be raised or lowered using the crank handle, and it can also be tilted to an angle of up to 45 degrees. The fence, on the other hand, can be moved across the table to accommodate workpieces of different sizes. It can also be adjusted in height using the knob at the back of the drill press.

Take note that these adjustments should be done carefully, with the utmost attention paid to safety. Always wear protective gear such as eye and ear protection, and avoid wearing any loose clothing or jewelry that might get caught in the moving parts. With a little practice and careful attention to safety, anyone can become an expert at adjusting the table and fence on the Manhattan Heavy Duty Drill Press.

Starting the Drill Press

Starting the Manhattan Heavy Duty Drill Press can seem intimidating, but it’s actually quite simple once you get the hang of it. First, make sure the drill bit is securely tightened in the chuck. Next, adjust the height of the table to the appropriate level for your project.

Then, turn on the machine and adjust the speed to your desired level. Always make sure to wear protective gear, such as safety glasses, when using any power tool. Remember to start the drill with a slow speed and gradually increase to avoid damage to your materials or the machine itself.

With a little practice, you’ll be able to confidently start the Manhattan Heavy Duty Drill Press and tackle any project with ease.

Conclusion

In the world of drilling, the Manhattan heavy duty drill press stands as a titan among tools. Its powerful motor and sturdy construction allow it to effortlessly power through nearly any material put in its path. The smooth operation and precise control of this machine make it a favorite among professionals and DIY enthusiasts alike.

Whether you’re woodworking, metalworking, or any other kind of drilling, the Manhattan heavy duty drill press will make sure your work is a cut above the rest. So, if you’re looking to drill like a pro, the Manhattan heavy duty drill press is the only way to go.”

FAQs

What is the capacity of the Manhattan Heavy Duty Drill Press?

The capacity of the Manhattan Heavy Duty Drill Press is up to 1 inch drilling in steel.

How does the Manhattan Heavy Duty Drill Press generate power?

The Manhattan Heavy Duty Drill Press generates power through a heavy duty induction motor.

What is the maximum spindle speed of the Manhattan Heavy Duty Drill Press?

The maximum spindle speed of the Manhattan Heavy Duty Drill Press is 3200 RPM.

How is the drilling depth controlled on the Manhattan Heavy Duty Drill Press?

The drilling depth on the Manhattan Heavy Duty Drill Press is controlled through a depth stop.

What material can be drilled with the Manhattan Heavy Duty Drill Press?

The Manhattan Heavy Duty Drill Press can drill materials such as steel, wood, aluminum, and plastic.

What is the size of the table on the Manhattan Heavy Duty Drill Press?

The table on the Manhattan Heavy Duty Drill Press is 9.5 inches by 9.5 inches.

How easy is it to change the speeds on the Manhattan Heavy Duty Drill Press?

The speed on the Manhattan Heavy Duty Drill Press can be changed easily with the use of the pulley system.