If you’re someone who is new to welding, one of the questions you might be asking yourself is how much power does a welding machine use? This is an important question to ask because it can affect not only your electricity bill but also the quality of your welds. In general, the amount of power a welding machine uses depends on a few key factors, such as the type of welding process you’re using, the thickness of the metal you’re welding, and the size of the machine itself. In this blog post, we’ll explore these factors in more detail to help you understand how much power you can expect your welding machine to use.

Understanding Power Consumption in a Welding Machine

When it comes to understanding power consumption in a welding machine, there are several factors to consider. The amount of power a welding machine uses mainly depends on its size and type. Smaller machines typically use anywhere from 30-140 amps of power, whereas larger machines can require up to 500 amps or more.

Another crucial factor is the type of material being welded. Different materials require different levels of heat and power to achieve a successful weld. The thickness of the material also plays a significant role in determining the amount of power required.

Generally speaking, thicker materials need more power to weld effectively. Additionally, the length of time the machine is in use affects power consumption as well. The longer a welding machine is in use, the more power it will consume.

Therefore, it is essential to use the appropriate size and type of welding machine for the specific job to save on energy costs.

Factors Affecting Power Consumption in a Welding Machine

Power Consumption, Welding Machine If you’re curious about the amount of electricity a welding machine consumes, there are several factors to consider. First, the type of welding process being used has a significant impact on power consumption. For instance, more energy-intensive processes like stick welding require more power than MIG or TIG welding.

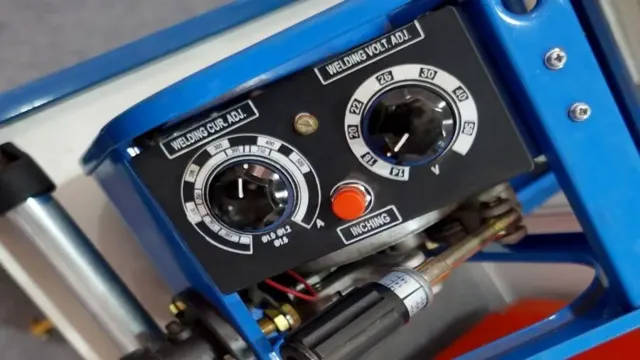

The voltage level selected also affects the amount of energy the machine uses, with higher voltages resulting in greater power consumption. Lastly, the thickness and composition of the metal being welded play a role, with thicker or more challenging metals requiring higher levels of power. It’s essential to choose a welding machine that suits your needs to ensure you use the appropriate amount of power for the task at hand.

By selecting the correct welding process, voltage level, and machine for the job, you can optimize your power usage and minimize waste while achieving the desired results.

Calculating Power Consumption in a Welding Machine

If you’re looking to purchase a welding machine, it’s important to understand how much power it will consume. The exact amount of power a welding machine uses will vary based on its size, type, and usage. Generally, a smaller welding machine will consume less power than a larger one.

Additionally, a machine with a higher amperage rating will consume more power than one with a lower amperage rating. When using the welding machine, the amount of power used will depend on the type of welding process used and the material being welded. For example, welding thick material will require more power than welding thin material.

All of these variables make it difficult to give a specific answer to the question of how much power a welding machine will use. However, many manufacturers provide an estimated power consumption for their machines on their websites or in their product manuals, which can be a helpful starting point for understanding the power requirements of your specific welding machine.

Formula for Calculating Power Consumption

Calculating power consumption of a welding machine can be done using a simple formula. First, you need to know the voltage and current rating of the machine. To get the power, you multiply the voltage by the current, that is, P = V x I.

For example, if your welding machine is rated at 220V and 30A, then the power consumption would be 220 x 30 = 6600 watts or 6 kW. This means that if you use the machine continuously for one hour, it will consume

6 kilowatt-hours (kWh) of electricity. It’s important to know the power consumption of your welding machine so that you can estimate how much electricity it will consume and plan your energy usage accordingly. This will help you save money on your electricity bill and reduce your carbon footprint.

Example Calculation for a 200 Amp Welding Machine

Calculating Power Consumption in a Welding Machine When it comes to welding machines, power consumption is a crucial factor to consider. To better understand this, let’s take a 200 Amp welding machine as an example. The first thing to note is that the power consumption of a welding machine is typically measured in kilowatts (kW).

In this case, a 200 Amp welding machine will typically require around 10 kW of power to operate at full capacity. However, it’s worth noting that the actual power consumption may vary depending on factors such as the duty cycle, the thickness of the materials being welded, and the length of time the machine is in use. To calculate the actual power consumption of a welding machine, you can use the following formula: Power Consumption = Voltage x Amperage So, for a 200 Amp welding machine operating at 230 volts, the power consumption would be: Power Consumption = 230 x 200 Power Consumption = 46,000 Watts (or 46 kW) It’s important to note that this is the maximum power consumption of the machine, and it may not always operate at full capacity.

To calculate the actual power consumption over a specific period of time, you’ll need to take into account the duty cycle of the machine. This is the percentage of time that the machine can operate at full capacity without overheating. For a 200 Amp welding machine, the duty cycle is typically around 60%, meaning that the machine can operate at full capacity for 6 minutes out of every

Overall, understanding the power consumption of a welding machine is essential for ensuring that it operates correctly and efficiently. By taking into account factors such as amperage, voltage, and duty cycle, you can calculate the actual power consumption of a machine and ensure that you’re using it safely and effectively.

Ways to Reduce Power Consumption in a Welding Machine

Welding machines are essential tools in many industries that require metal fabrication and repair work. As useful as they are, they can also be power-hungry and expensive to run. If you’re wondering how much power does a welding machine use, the answer is that it varies depending on the specific model.

Some machines may consume as little as 100 watts, while others use as much as 15,000 watts. To reduce power consumption, you can take several steps, including cleaning and maintaining the machine, using energy-efficient accessories, adjusting the welding voltage and amperage to the optimal levels, and choosing a machine with a high power factor. You can also consider using alternative welding methods like gas tungsten arc welding or plasma arc welding, which may consume less energy than traditional welding techniques.

By taking these steps, you can reduce the amount of power your welding machine consumes, lower your energy costs, and minimize your environmental impact.

Regular Maintenance and Repairs

If you own a welding machine, you know that it can consume a lot of energy, particularly if you use it frequently. However, there are several simple ways you can reduce the power consumption of your welder. One of the most effective methods is to maintain your machine regularly and repair it as needed.

By keeping your welding machine in peak condition, it will run more efficiently and use less energy. Another way to reduce power consumption is to use a machine that is appropriately sized for the job at hand. Using a machine that is too large will waste energy and money.

Additionally, turning off your welding machine when not in use and adjusting settings such as voltage and amperage to the minimum required will also help save power. By implementing these strategies and performing regular maintenance and repairs, you can reduce your welding machine’s power consumption and save energy and money in the process.

Proper Use and handling of the Welding Machine

When it comes to welding machines, power consumption is a major concern for users. However, there are some easy ways to reduce it. One effective solution is to adjust the voltage and amperage settings.

By doing so, you can prevent excess power usage and improve the efficiency of the machine. Another way to reduce consumption is to avoid leaving the machine running for long periods of time when it isn’t being used. This can be done by ensuring that the machine is turned off when it isn’t in use or by using a power-saving mode if available.

Additionally, using high-quality welding electrodes can result in less power usage and increase the lifespan of the machine. Practicing proper welding techniques such as not changing the polarity while welding and maintaining the machine regularly can also significantly reduce power consumption. By implementing these simple solutions, you can reduce power consumption without sacrificing the quality of your weld and decrease energy costs.

Choosing Energy-Efficient Welding Equipment

When it comes to welding equipment, energy efficiency is an important consideration. Not only can it reduce the power consumption of your machine, but it can also save you money on your energy bills. One way to reduce power consumption is by using an inverter-based welding machine.

These machines use high-frequency switching to provide a more stable arc while consuming less power. Another option is to choose a machine with a sleep mode feature. This feature will automatically turn off the power when the machine is not in use, reducing power consumption and saving you money.

Additionally, you can consider machines with advanced energy-saving technologies such as capacitive discharge, which stores and releases energy more efficiently, reducing power consumption and prolonging the life of the machine. With these options and more, it’s possible to choose an energy-efficient welding machine that will not only save you money, but also reduce your carbon footprint.

Conclusion

In conclusion, the power consumption of a welding machine can vary depending on the type and size of the machine, the welding process, and the thickness and type of metal being welded. However, one thing is certain – a welding machine has the power to transform raw materials into beautiful and functional works of art. So, when it comes to unleashing the power of a welding machine, the only limit is your creativity and imagination!”

FAQs

What is the average power consumption of a welding machine?

The average power consumption of a welding machine depends on its type and size. Typically, small to medium welding machines consume anywhere from 10 to 100 amps, while larger industrial models consume over 100 amps.

How much does it cost to run a welding machine?

The cost to run a welding machine depends on various factors, including electricity rates, the machine’s power consumption, and the duration of use. As an estimate, running an average welding machine for one hour would cost between $0.10 and $1.00.

Can welding machines run on a generator?

Yes, welding machines can run on a generator. However, it is essential to ensure the generator’s capacity is sufficient to power the machine, including any additional tools or accessories.

What is the power factor of a welding machine?

The power factor of a welding machine refers to the ratio between the electrical power consumed and the power used for welding. The power factor typically ranges from 0.3 to 0.7 for welding machines, with higher values indicating greater efficiency.

How can I reduce my welding machine’s power consumption?

You can reduce your welding machine’s power consumption by using a machine with a higher power factor, turning off any unnecessary accessories or functions, using the correct welding technique and settings, and maintaining your machine’s components regularly.

Can I weld with a low power welding machine?

Yes, it is possible to weld with a low power welding machine. However, the thickness and type of materials you can weld may be limited. Low power machines are typically suitable for thin sheets of metal or light-duty welding applications.

How long can I run a welding machine continuously?

The duration a welding machine can be run continuously depends on its size, type, and cooling system. Small to medium welding machines can typically run for 20 minutes to one hour before requiring a break to cool down. Larger industrial models may run for several hours or even continuously with proper cooling and maintenance.