As a mechanic or a DIY handyman, one of the essential tools in your arsenal should be a torque wrench. However, if you’re new to the game, some of the tool’s features might be perplexing. You might ask yourself, how big of a torque wrench do you need? Well, the answer is not a simple one.

It depends on the kind of work you plan on doing. Just like a runner requires different shoes for different terrains, a mechanic requires different torque wrenches for different angles and strengths. In this blog, we will explore the ins and outs of torque wrenches, their sizes, and their uses, helping you make an informed decision when it comes to purchasing the ideal wrench.

So, let’s dive in and burst the bubble around selecting the perfect torque wrench.

Understanding Torque Wrenches

When it comes to selecting the right torque wrench for your specific needs, the size of the wrench plays a critical role. The question of how big of a torque wrench you need depends on the type of task you’re undertaking. A general rule of thumb is that your wrench should have a torque rating that exceeds the maximum torque required for the job.

For example, if your job requires a maximum torque of 100 ft-lbs, you should choose a wrench with a torque rating of at least 120 ft-lbs. This buffer provides some flexibility and ensures that the wrench won’t be operating at its maximum capacity, which can cause inaccuracies. Additionally, consider the size and accessibility of the bolt or nut you’re tightening.

A larger wrench may be required if the bolt requires more force or if you have limited space in which to work. Taking the time to select the right size torque wrench will provide you with more accuracy and efficiency in completing your task.

Definition and Types

Torque wrenches are essential tools used to tighten bolts and nuts to a specific torque, ensuring accuracy and preventing damage to the material being fastened. These wrenches come in various types, including beam, click, and digital torque wrenches. Beam torque wrenches work by bending a metal bar as force is applied, with the user reading the torque from a scale on the wrench.

Click torque wrenches emit an audible click sound when the torque has been achieved, indicating that it’s time to stop. Digital torque wrenches, on the other hand, display the torque reading on a digital display, making them the most precise and easy to read. Each type of torque wrench has its own advantages and disadvantages, so it’s crucial to consider which one suits your needs when selecting a torque wrench for your project or profession.

But ultimately, regardless of the type, torque wrenches have become essential in the mechanical world, ensuring that every bolt or nut is precisely tightened to achieve optimal performance.

How They Work

Torque wrenches are amazing mechanical tools that are used to tighten nuts and bolts to a specified torque value. In simple terms, torque is the rotational force required to tighten a bolt or nut to a prescribed degree. That said, torque wrenches come in different types, including beam, click, dial, and digital torque wrenches, and each works uniquely.

For instance, a beam torque wrench has a simple design and operates by deflecting a beam to indicate the torque applied. On the other hand, click torque wrenches signal the application of torque by producing an audible “click” sound. Dial torque wrenches and digital torque wrenches indicate the torque applied on a dial or display, respectively.

By using torque wrenches, you can tighten bolts perfectly without damaging the thread or fastener. In addition, torque wrenches come in handy when working with car engines, heavy machinery, and any application involving tightening and loosening bolts requiring specific torque values.

Factors to Consider

Are you wondering how big of a torque wrench you need for your next project? There are several factors to consider when selecting the right size torque wrench. Firstly, you want to determine the torque specifications for the bolts you will be working with. Once you know the torque range, it is best to choose a torque wrench that covers the middle of that range.

For example, if your torque specifications range from 50-200 ft-lb, a 100-150 ft-lb torque wrench would be a good choice. Additionally, consider the size and accessibility of the bolts. A smaller torque wrench may be needed for tight spaces or small bolts.

However, for larger bolts, you may need to use a longer torque wrench to apply adequate force. Finally, consider the frequency of use. If you will be frequently using the torque wrench, it is best to invest in a high-quality tool that will last for years.

Remember, using the wrong size torque wrench can result in over or under-tightening, causing damage to your equipment or even risking injury. So take your time and choose the proper size torque wrench for the job at hand.

Application

When it comes to choosing an application to use, there are several factors to consider to ensure that you are getting the best fit for your needs. Firstly, you should evaluate the application’s user interface and design. The user interface should be easy to navigate, and the design should be visually pleasing.

Secondly, you should consider the application’s functionality. Does it offer all the features that you require? Will it work seamlessly with your operating system and other software applications? Thirdly, take note of the support and resources available for the application. Does the company offer regular updates and fixes for bugs? Fourthly, consider the cost of the application and its value for money.

Finally, user reviews and feedback can provide valuable insight into the application’s compatibility and effectiveness. Whether you’re choosing an application for personal or business use, taking the time to evaluate these factors can ensure that you make an informed decision and select the best application for your needs.

Bolt Size and Tightening Specification

When it comes to selecting the appropriate size and tightening specification for bolts, there are a few crucial factors to consider. The first factor is the load that the bolt will need to withstand. Depending on the load, a different size and specification may be needed.

It’s vital to select a bolt that is strong enough to handle the load but not too strong that it puts unnecessary pressure on other parts of the equipment. The second factor is the type of material that the bolt will be installed in. Different materials have different requirements when it comes to bolt size and tightening specification.

Lastly, the environmental conditions where the bolt will be installed need to be considered. If it’s going to be in a harsh environment, a stronger bolt with a higher tightening specification may be required. By considering these factors, you can choose the right bolt size and tightening specifications to ensure the safety and reliability of your equipment.

Material of Fasteners and Components

When it comes to selecting the right fasteners and components for your project, the material used is a crucial factor to consider. Different materials have varying properties that can affect the overall strength, durability, and performance of the fasteners and components. For example, if you need corrosion-resistant and high-strength fasteners, stainless steel or titanium may be the best options.

On the other hand, if you’re looking for a cost-effective option, carbon steel or brass may be suitable. Additionally, the environment and application of the fastener and component should also be considered. Are they exposed to high temperatures, corrosive chemicals, or high pressure? These factors can impact material choice as well.

Ultimately, taking the time to carefully consider the material of your fasteners and components can lead to a successful and long-lasting project.

Space Constraints and Torque Range

When it comes to selecting the right torque range, there are a few factors that engineers need to consider, one of which is space constraints. Depending on the size and shape of the application, there may only be a limited amount of space available for the torque tool. In such cases, it becomes crucial to choose a tool that can operate efficiently within those confined spaces.

Another crucial factor to consider is the required torque range. The range is essential because it determines the effectiveness and accuracy of the tool. The torque range needs to be precise enough to provide accurate results while also having enough flexibility to adjust to different applications.

Finding the right balance is crucial to ensure that the tool can handle a variety of tasks while delivering the desired results. Overall, selecting the right torque tool requires careful consideration of both space constraints and torque range to ensure that the tool can deliver the best performance for the intended application.

Choosing the Right Torque Wrench

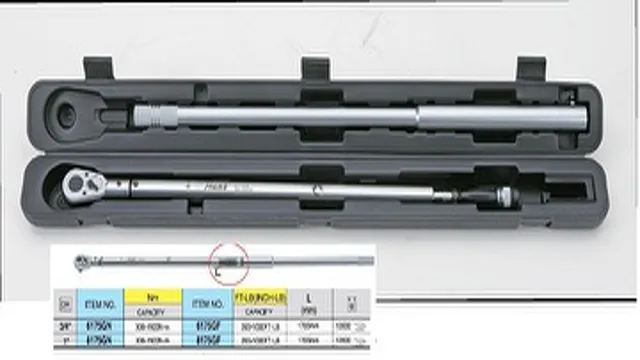

When looking for a torque wrench, one of the biggest questions you may ask is “how big of a torque wrench do I need?” The answer to this question depends on the specific application you will be using the wrench for. Typically, torque wrench sizing is determined by the maximum torque value required for the job. It’s essential to consider the size and strength of the bolts you will be working with as well as the torque specifications provided by the manufacturer.

If you choose a wrench that’s too small, you risk over-tightening the bolts, while a wrench that’s too big may not give you the precision you need. It’s essential to choose a torque wrench that’s appropriate for your needs to ensure that you have the necessary accuracy and torque strength to get the job done right.

Calculating Required Torque Range

When working with equipment that requires precise tensioning or loosening of bolts and nuts, choosing the right torque wrench is crucial. One of the main factors to consider when selecting a torque wrench is calculating the required torque range. This involves assessing the specific application and determining the maximum and minimum torque values required.

It’s important to keep in mind that using a torque wrench outside of its specified range can cause equipment damage or injury to personnel. Therefore, selecting a wrench with a suitable torque range is essential to ensure optimal performance and safety. By taking into account the application’s requirements and carefully calculating the necessary torque range, you can choose the right torque wrench for the job and carry out tasks with precision and confidence.

Types of Torque Wrenches

Choosing the right torque wrench can seem overwhelming with so many different types available. It’s important to consider the job you’re doing, the required torque setting, and the size of the bolts or nuts you’ll be tightening. A beam type torque wrench is a simple and affordable option that uses a calibrated rod to show the amount of torque being applied.

Click-type torque wrenches emit a clicking sound when the desired torque level is reached, making them popular for their accuracy and ease of use. For harder to reach areas, a crowfoot torque wrench with an extension bar may be necessary. Electronic torque wrenches are becoming more popular because of their digital display and ability to store data.

No matter which type of torque wrench you choose, remember to properly calibrate and maintain it for accurate and safe use.

Conclusion

In conclusion, choosing the right torque wrench is all about balance. You want a wrench that’s big enough to handle the task at hand, but not so big that you risk damaging your equipment. It’s like Goldilocks said: not too big, not too small, but just right.

So, go ahead and do your research, crunch those numbers, and find the torque wrench that will help you achieve that perfect balance. Just remember – when it comes to torque wrenches, size really does matter!”

FAQs

What is torque and why is it important for mechanical work?

Torque is a measure of rotational force that is necessary for tasks such as loosening or tightening bolts and nuts. It is crucial for ensuring the safety and functionality of machinery.

How do I determine the appropriate size of a torque wrench for a specific job?

The appropriate size of a torque wrench for a specific job depends on the size of the bolt or nut being tightened and the level of torque required. Consult a torque chart or a professional to ensure proper sizing.

Can I use a torque wrench for tasks other than adjusting nuts and bolts?

Yes, torque wrenches can be used for other tasks that require specific levels of rotational force, such as adjusting bike pedals or setting headspace on firearms.

What is the difference between a click-type torque wrench and a beam-style torque wrench?

A click-type torque wrench makes an audible click when the desired torque level has been reached, while a beam-style torque wrench uses a visual indicator, such as a pointer, to show when the desired torque level has been reached.

Is calibration necessary for torque wrenches?

Yes, torque wrenches should be calibrated regularly to ensure accurate readings. Consult the manufacturer’s instructions for recommended calibration intervals.

Can a torque wrench be damaged or broken?

Yes, misuse or mishandling of a torque wrench can lead to damage or breakage. Follow proper use and maintenance procedures to ensure the longevity of your tool.

What are some common mistakes to avoid when using a torque wrench?

Some common mistakes to avoid when using a torque wrench include using the wrong size wrench, applying too much force, or not checking calibration before use. Always consult the manufacturer’s instructions and use proper technique.