Have you ever struggled to find the right sized hose clamp for your project? It can be frustrating to try and measure a clamp that seemingly has no discernible measurements or markings. But fear not! Learning how to measure hose clamps is not as daunting as it may seem. In fact, it is quite simple and straightforward.

In this blog, we will walk you through the steps on how to accurately measure hose clamps so that you can confidently choose the correct size for your application. So let’s dive in and become experts on hose clamp measurements!

Introduction

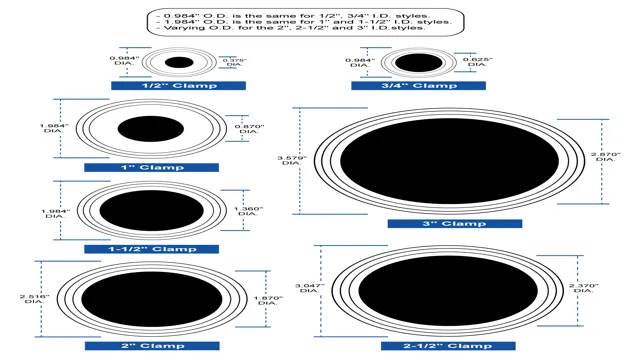

If you’re wondering how to measure hose clamps, you’ve come to the right place. Hose clamps come in various sizes, and determining the correct size is crucial for a secure and tight fit. To measure a hose clamp, you will need to know its diameter.

You can use a ruler or a measuring tape to measure the diameter of the hose you want to clamp. Then, use a hose clamp sizing chart to determine the appropriate clamp size. The chart will list the size range of clamps for the hose diameter, and you can choose the size that matches your hose’s diameter.

It’s important to remember that a clamp that’s too small won’t provide a secure fit, while a clamp that’s too big will be loose and ineffective. By measuring your hose clamps accurately, you can ensure that they fit perfectly and do the job they’re intended to do.

What are hose clamps?

Hose clamps are devices used to secure hoses onto fittings or connections, preventing leaks or disconnections. They come in various shapes and sizes, depending on the application and the type of hose being used. Their function is simple yet crucial, making them a staple in various industries such as automotive, plumbing, and agriculture.

At their most basic, hose clamps are made up of a band or strap that can be tightened around the hose with a screw or other mechanism. This band is typically made of metal or plastic, and the tightening mechanism can vary from a simple thumbscrew to a specialized tool. Hose clamps are easy to install and remove, making them a convenient solution for securing hoses in tight spaces or hard-to-reach areas.

Whether you’re working on your car or irrigating your crops, hose clamps are essential components that provide peace of mind and reliable performance.

Importance of proper measurement

Measurement is a critical component in every aspect of life. It helps us understand the world around us, track progress, and improve performance. Proper measurement ensures that we have accurate data that we can rely on to make informed decisions.

The importance of proper measurement cuts across different fields, from science and engineering to healthcare, sports, and business. By accurately measuring variables such as distance, time, weight, temperature, and pressure, we can develop models, draw conclusions, and identify patterns that would otherwise be difficult to see. The keyword, “proper measurement,” emphasizes the significance of accuracy and precision when recording data.

It highlights the need for attention to detail and the ability to obtain reliable results that can withstand scrutiny. Ultimately, proper measurement is essential in attaining excellence in any endeavor.

Tools needed

If you’re wondering how hose clamps are measured, there are a few tools you’ll need to get the job done. First things first, you’ll need a measuring tape or ruler. The most common type of hose clamp is the worm gear clamp, which typically ranges in size from about 7/32″ to 2-3/4″ in diameter.

To measure the diameter of your hose, you’ll want to wrap the measuring tape or ruler around the outside of the hose. Take note of the measurement in inches, and you’ll be able to select the appropriate size clamp for the job. Another tool that can come in handy when working with hose clamps is a screwdriver or wrench.

These tools will allow you to adjust the clamp as needed to ensure a secure fit around the hose. By using these simple tools, you’ll be well on your way to measuring and installing hose clamps like a pro.

Measuring tape or ruler

To accurately measure length, width, or height, you’ll need either a measuring tape or a ruler. Both tools are essential in any DIY or crafting project and ensure accurate measurements. Although these tools may seem similar, they have distinct features and are used for different tasks.

Let’s start with a measuring tape. This tool is flexible and usually made from cloth, plastic, or metal. It’s perfect for measuring curved or irregular surfaces since it can adapt to the shape of the object being measured.

A measuring tape is ideal for measurements such as circumference or diameter, and it’s also handy for taking quick and easy measurements. On the other hand, a ruler is a rigid and straight tool with evenly spaced markings that are usually in inches, centimeters, or both. It’s better suited for measuring straight lines and angles.

Rulers come in various lengths, including 12 inches, 18 inches, or even meters, allowing for precise measurements of larger objects. When it comes to choosing which tool to use, it depends on the task at hand. If you need to measure around a circular object or need to take quick measurements, a measuring tape would be perfect.

However, for precise measurements of straight lines and angles, a ruler is the tool for the job. In conclusion, both measuring tape and ruler are essential tools for any DIY or crafting project. They serve different purposes, but together they ensure accurate measurements, leading to successful projects!

Diameter tape

When it comes to measuring the diameter of trees, a diameter tape is an essential tool to have in your arsenal. This specialized tape measure typically features large, easy-to-read numbers and a unique design that allows you to wrap it around the tree trunk and obtain an accurate measurement of its circumference. To use a diameter tape, simply wrap it around the tree trunk at breast height and read the measurement on the tape.

Some diameter tapes even come with additional markings and tables that allow you to quickly convert circumference measurements into diameter measurements. When selecting a diameter tape, be sure to choose one that is durable and well-made, as it will likely see a lot of use over its lifetime. With a diameter tape in your tool bag, you’ll never have to guess the size of a tree again.

Measuring methods

If you’re wondering how hose clamps are measured, the process is straightforward and essential to ensure a proper fit. The first step is to measure the diameter of the hose you want to clamp. Then, you’ll need to determine the range of the clamp that will fit your hose.

This can be done by measuring the clamp’s inside diameter when it’s closed and comparing it to the hose’s outer diameter. You can find this information on the clamp’s packaging or by contacting the manufacturer. Keep in mind that there are different types of hose clamps, so be sure to choose the correct one for your application.

By measuring your hose and choosing the appropriate clamp, you can ensure a secure connection and prevent leaks. So, whether you’re working on a plumbing project or automotive repair, taking the time to measure your hose clamps correctly is crucial.

Method 1: Diameter measurement

When it comes to measuring the size of an object, especially one that has a circular shape, one of the most accurate methods is diameter measurement. This process involves measuring the distance from one end of the circle to the other, passing through the center. To do this, you need a measuring tool, such as a ruler or a caliper, that can accurately measure the diameter of the circle.

Once you have your measuring tool, place one end on the edge of the circle and extend it to the opposite edge while making sure that it passes through the center. Take note of the measurement and repeat the process to ensure accuracy. This method of measuring is commonly used in various industries, such as construction and engineering, where precise measurements are crucial for the success of a project.

By using the diameter measurement method, you can achieve accurate measurements that will help you achieve your desired outcomes.

Method 2: Circumference measurement

If you’re looking for a more accurate way to measure your body fat, the circumference measurement method may be right for you. This method involves measuring the circumference around specific parts of your body, including your waist, hips, and thighs. To start, wrap a measuring tape around your waist at your belly button and take note of the measurement.

Then, measure the widest point of your hips and divide that number by the waist measurement. This will give you your waist-to-hip ratio, which can be used to determine your level of body fat. For women, you can also measure the circumference of your thighs at the widest point and divide that number by your waist measurement.

This can give you additional insight into your body fat distribution. Overall, the circumference measurement method is a simple and effective way to monitor changes in your body fat levels over time. Just be sure to take accurate measurements and track your progress consistently to see the best results.

Tips for accurate measurement

If you are looking to purchase a new hose clamp, it is crucial to measure it accurately to ensure a proper fit. The most common method for measuring hose clamps is to measure the outside diameter of the hose they will be securing. It is essential to measure the diameter of the hose with precision, as even a small discrepancy in measurement can cause the hose clamp to not fit correctly.

To measure the outside diameter of the hose, you can use a caliper or a tape measure, depending on the hose’s size. It is recommended to take multiple measurements at different points of the hose to ensure accuracy. Additionally, it is important to consider the type of hose clamp needed for the job, as there are various types available, from worm gear clamps to spring clamps.

Taking accurate measurements and using the appropriate hose clamp type will ensure a secure and leak-free connection.

Avoid stretching the hose

When measuring a garden hose, it’s important to avoid stretching it. This might seem like common sense, but it’s an easy mistake to make. Stretching the hose can lead to inaccurate measurements and cause the hose to burst in the future.

To get an accurate measurement, start by laying the hose out straight on a flat surface. Make sure it’s not touching any objects that might interfere with the measurement. Then, use a tape measure or ruler to measure from one end of the hose to the other.

Keep in mind that the length of the hose can change slightly depending on the temperature, so it’s best to measure on a mild day. By taking the time to measure your hose accurately, you can ensure that you buy the right size replacement hose or nozzle and avoid any unexpected leaks or bursts in the future.

Measure multiple points

When it comes to accurate measurement, taking readings from just one point may not be enough. To ensure precision, it’s essential to measure multiple points. This is especially important when working with larger areas or diverse surfaces.

By measuring multiple points, you can identify inconsistencies and make adjustments accordingly. Some tips for taking measurements from multiple points include using a consistent technique and taking readings from evenly spaced areas. This will help ensure you get an accurate representation of the surface or area you are measuring.

Remember, when it comes to measurement, precision is key, and measuring from multiple points will help you achieve that goal.

Conclusion

In sum, measuring hose clamps is like playing a game of precision placement and tight fit. To get the right size, you need to know the diameter of your hose, the exact measurement of the space where the clamp will fit, and the degree of clamping force required. It’s all about finding that perfect match – not too big, not too small, but just right.

In other words, measuring hose clamps is a balancing act between science and fairy tale Goldilocks’ story!”

FAQs

What is the standard method of measuring hose clamps?

The standard method of measuring hose clamps is to measure the diameter of the hose and choose a clamp that matches that diameter.

What tools are needed to measure hose clamps?

A caliper or a tape measure can be used to measure the diameter of the hose, and then the appropriate clamp can be selected.

Can hose clamps be reused?

It is generally not recommended to reuse hose clamps as they may have become worn or damaged during their previous use.

How tight should a hose clamp be?

A hose clamp should be tightened just enough to create a secure seal, but not so tight that it damages the hose or restricts flow.

What materials are hose clamps made of?

Hose clamps can be made of various materials such as stainless steel, brass, or plastic, depending on the intended use and environment.

What is the maximum pressure that a hose clamp can withstand?

The maximum pressure that a hose clamp can withstand depends on the size and material of the clamp, but most are designed to handle pressures up to 60 PSI.

Are there different types of hose clamps for different hoses?

Yes, there are different types of hose clamps that are designed for use with specific types of hoses, such as automotive fuel hoses or industrial hoses.