Do you ever find yourself needing to cut through metal, but are unsure what tool to use? While many people turn to heavy-duty equipment such as plasma cutters or angle grinders, you may be surprised to learn that wire cutters have the potential to do the job just as effectively. Yes, you read that right – wire cutters. But the question remains: can wire cutters really cut through metal? This may seem like a simple yes or no question, but it’s important to understand the different types of wire cutters and the metals they are capable of cutting before drawing any conclusions.

In this blog, we’ll take a closer look at the world of wire cutters and their capabilities when it comes to cutting metal.

Understanding Wire Cutters

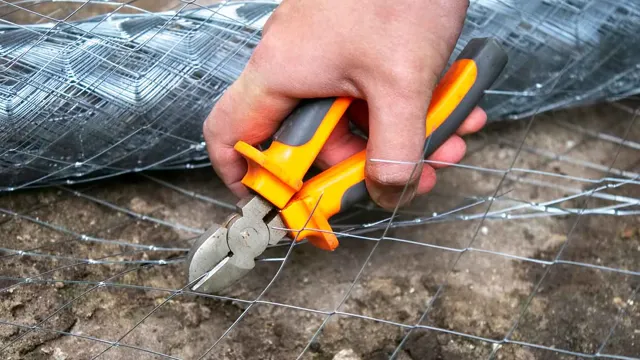

“Can wire cutters cut through metal?” is a common question asked by those who work with wires and other materials. The answer is that it depends on the type of wire cutters being used and the type of metal you’re trying to cut. Some wire cutters are designed specifically to cut through metal, such as those used in electrical work.

However, if you’re trying to cut through thicker or stronger types of metal, you may need to use a different tool, such as pliers or bolt cutters. It’s essential to choose the right tool for the job to ensure safety and efficiency. When using wire cutters, it’s important to wear gloves to protect your hands and to use them correctly to avoid injury.

In summary, wire cutters can cut through some types of metal, but it depends on the tool’s strength and the metal’s thickness. Always choose the appropriate tool for the job and use it correctly to ensure safety and efficiency.

Different Types of Wire Cutters and Their Uses

Wire cutters are an indispensable tool for any electrician, craftsman, or DIY enthusiast. They are used to cut wires, cables, and other tough materials with ease. However, not all wire cutters are the same, and understanding their differences can make a huge difference in the result of your project.

There are several types of wire cutters, including diagonal cutters, end cutters, and cable cutters. Each type of wire cutter is specifically designed for a particular use, and using the wrong type of cutter can result in damage to the tool, injury to the user, or poor quality cut. To choose the right wire cutter, consider the type of material you will be cutting, the thickness of the wire, and the level of precision required.

With the right wire cutter, you can ensure a clean, precise cut every time.

Types of Metals and Wire Cutter Compatibility

Wire cutters are designed to cut through wires and cables but they can also cut through some metal materials. The type of metal and the wire cutter compatibility are important factors to consider. There are different types of metals such as stainless steel, copper, aluminum, and iron.

Stainless steel is a popular metal but it can be challenging to cut. Wire cutters that are made of hardened steel can cut through stainless steel. Copper and aluminum are soft metals that are easy to cut.

Small and handheld wire cutters can be used to cut through these metals. On the other hand, iron is a hard metal and it requires strong wire cutters that are designed to cut through hard materials. It’s important to choose the appropriate wire cutter that suits the type of metal being cut to achieve efficient and quality results.

Can wire cutters cut through metal? The answer is yes, but it ultimately depends on the type of metal and the wire cutter compatibility.

Soft Metals that Wire Cutters can Cut Through

When it comes to wire cutters, not all metals are created equal. While some wire cutters can handle the toughest and thickest metals, others might struggle with softer, more malleable metals. As a general rule, wire cutters are compatible with metals that are easy to cut, such as copper, brass, and aluminum.

These metals are relatively soft and can be cut cleanly and easily with most wire cutters. However, if you are working with harder metals, such as steel or iron, you will need to choose a wire cutter specifically designed to handle these tougher materials. By understanding the types of metals you are working with and choosing the right wire cutter for the job, you can ensure that your cuts are clean and precise every time.

Hard Metals that Wire Cutters Cannot Cut Through

Wire cutters are a must-have tool for anyone working with wires. However, some metals are too hard for them to cut through. It’s important to know which types of metals are compatible with wire cutters before attempting any cutting.

For instance, titanium and tungsten are two types of metals that are tough to cut through with wire cutters. Not only are they hard, but they’re also very dense, which makes cutting through them even more challenging. In such cases, it’s better to use other tools like saws or grinders that can handle the hardness of these metals.

It’s crucial to use the right tool for the job to avoid damaging the wire cutters or getting injured while trying to cut through these hard metals.

Factors that Affect Wire Cutter Performance on Metals

Yes, wire cutters can cut through metal, but the effectiveness and performance depends on various factors. The hardness of the metal, the thickness of the wire, and the quality of the wire cutter can influence the ability to cut through the metal. Harder metals like steel and iron require more force and pressure to cut through, and wire cutters with a higher level of durability and strength are necessary for optimal results.

Additionally, the thickness of the wire can also impact the wire cutter’s performance. Thicker wires require greater cutting power and a sturdier grip. It is important to select a wire cutter that is appropriate for the specific wire thickness and metal type to ensure proper and efficient cutting.

In summary, when considering cutting metal with wire cutters, ensure that the cutter is compatible with the type of metal and wire thickness being cut to achieve effective and efficient results.

Thickness and Hardness of the Metal

When it comes to choosing the right wire cutter for metals, two factors to consider are the thickness and hardness of the metal being cut. Thinner and softer metals like aluminum and copper can be easily cut with basic wire cutters, whereas thicker and harder metals like steel can require heavy-duty cutters with specially designed blades. It’s important to choose the right cutter for the job to avoid damaging the tool or producing a poor-quality cut.

Think of it like using a regular pair of scissors to cut through cardboard versus trying to cut through a tough leather belt – the scissors may not hold up to the task and the cut may end up jagged and uneven. By taking the time to assess the thickness and hardness of the metal, you can select the appropriate wire cutter to achieve a clean and precise cut every time.

Quality and Sharpness of the Wire Cutter Blades

When it comes to wire cutters, the quality and sharpness of the blades are crucial factors that affect their performance on metals. High-quality wire cutter blades are made from durable materials and are designed to withstand the rigors of cutting through tough metals. The sharpness of the blades also plays an important role in how well they perform.

Dull blades can cause unnecessary strain on the tool and can make it difficult to cut through even the thinnest wires. To ensure optimal performance, it’s important to invest in a set of wire cutters that come with high-quality and sharp blades. With the right tool, cutting through metals can be a breeze, and you can be sure that your wires will be cut cleanly and precisely every time.

So, the next time you’re shopping for wire cutters, keep in mind the importance of quality and sharpness in the blades for optimal performance on metal wires.

Size and Strength of the Wire Cutter

When it comes to wire cutters, the size and strength of the tool can greatly impact its performance on different types of metals. The size of the cutter blades will determine the amount of force that can be applied to the metal being cut, with larger blades able to cut through thicker pieces with more ease. On the other hand, the strength and durability of the tool will determine how long it can last and how frequently it can be used before needing maintenance or replacement.

Other factors that can affect wire cutter performance on metals include the sharpness of the blades and the angle at which they are applied to the metal. With the right size and strength, a wire cutter can easily cut through even the toughest metals with precision and ease.

Conclusion

In the battle between wire cutters and metal, it is a tale of David vs. Goliath. While wire cutters may be mighty in their ability to slice through thin wires and cables, trying to take on metal with them is like trying to use a toothpick to clear a path through a forest.

So, can wire cutters cut through metal? The answer is no, my friends. Let’s leave that job to the big boys.”

FAQs

What type of metal can wire cutters cut through?

Wire cutters can cut through softer metals such as aluminum and copper, but may not be able to cut through thicker or harder metals like steel.

Can all wire cutters cut through metal or do I need a specific type?

Wire cutters come in different sizes and strengths, so it’s important to use the appropriate wire cutters for the type and thickness of metal you need to cut.

Are there any safety precautions I should take when cutting metal with wire cutters?

Yes, always wear safety goggles to protect your eyes from any metal shavings that may fly off during cutting. It’s also important to have a firm grip on the metal being cut and to be aware of any potential hazards in your surroundings.

Can wire cutters damage the metal being cut?

Depending on the type of wire cutters and the strength of the metal being cut, there is a possibility that wire cutters could leave marks or small indentations on the metal. Additionally, improperly cutting thicker or harder metals could cause damage to the wire cutters themselves.

What is the maximum thickness of metal that wire cutters can cut?

The maximum thickness of metal that wire cutters can cut varies depending on the strength and size of the wire cutters. Generally, wire cutters can cut through metals up to 1/8 inch thick.

Can wire cutters be used for other purposes besides cutting wire and metal?

Yes, wire cutters can be used for a variety of tasks including cutting plastic, trimming small plants, and even cutting fishing line.

Do I need to lubricate my wire cutters when cutting through metal?

It’s not necessary to lubricate wire cutters when cutting through metal, but doing so may help prolong the life of the cutters and make cutting smoother. Be sure to use a lubricant that is safe for use on both the metal being cut and the wire cutters themselves.