Screws are essential in the world of DIY for various home improvement projects. But what happens when a screw becomes stripped or needs to be removed? This is where the trusty wire cutter comes into play – known for its ability to cut through wires, but can it also handle cutting screws? If you’ve ever found yourself in this situation, you might have wondered, can wire cutters cut screws? Well, the answer isn’t as straightforward as a simple “yes” or “no.” In this blog post, we’ll explore the ins and outs of wire cutters, screws, and whether the two are a match made in heaven or a recipe for disaster.

So, let’s dive in and find out if wire cutters are up to the task of cutting screws.

Understanding Wire Cutters

Wire cutters are a handy tool to have for any DIY project or repair job. But can wire cutters cut screws? The short answer is no, wire cutters are not designed to cut through screws. While wire cutters have sharp blades that can easily snip through thin wires and cables, screws are made of harder metals that are difficult to cut through.

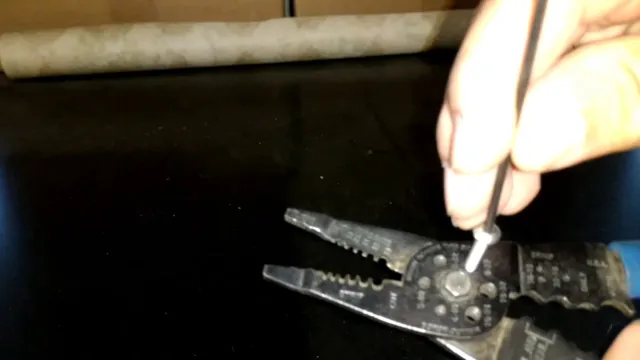

However, that’s not to say that wire cutters aren’t useful for working with screws. An example of where wire cutters can come in handy when working with screws is when trying to remove a stripped screw. By using the wire cutters to grip onto the screw head and turn it, you may be able to loosen it and remove it more easily.

It’s important to always use the right tools for the job to avoid damaging your tools or injuring yourself.

Types of Wire Cutters

Wire cutters are essential tools for anyone that’s working with electrical wires or similar material. While they may all look similar, there are actually various types of wire cutters designed for specific purposes. Understanding the different types can make a big difference in the precision and accuracy of your cuts.

One common type is the diagonal cutting pliers, which have a sharp edge that is at an angle to the handles, allowing it to cut wires close to a surface. Another type is the end cutting pliers, which have a flat cutting surface that can make flush cuts. If you’re working with thicker wires, you may need to use heavy-duty wire cutters, which have jaws that are designed to handle the added force required.

It’s important to note that not all wire cutters are created equal, so make sure you choose the right type for your specific task. Whether you’re a professional electrician or a DIY enthusiast, having the right tool for the job is crucial for getting the results you need.

How Wire Cutters Work

Wire cutters are an essential tool for anyone who works with wires, whether you’re an electrician or a DIY enthusiast. But have you ever wondered how wire cutters work? These pliers-like tools are specially designed to cut through wires of all thicknesses. Wire cutters have two sharp blades that are joined together in a pivot, allowing the jaws of the tool to open and close.

When the handles of the wire cutters are squeezed, the blades come together, snipping through the wire. The thickness of the wire determines the size of the wire cutters needed to cut through it. For instance, thicker wires require larger wire cutters.

It is important to choose the right pair of wire cutters for the job to ensure quality and efficient work. When choosing wire cutters, consider the type of wire you’ll be cutting, the size of the cutters you need, and the comfort and grip of the tool. A good pair of wire cutters should also be durable and made of high-quality materials to withstand frequent use.

With the right pair of wire cutters, you can effortlessly cut through wires with ease, saving time and energy on your projects. Whether you’re a professional electrician or a DIY enthusiast, understanding wire cutters and how they work is essential for improving your work efficiency.

Types of Screws

Yes, wire cutters can cut screws, but whether they can effectively do so depends on the size and type of screw. There are a variety of screw sizes and types, each with different threads and heads, and not all wire cutters will be able to cut through all of them. For example, wire cutters are typically not strong enough to cut through large metal screws, lag bolts, or deck screws.

However, they may be able to cut through smaller screws like wood screws or sheet metal screws. It’s also important to note that cutting screws with wire cutters may damage the tool, so it’s generally not recommended. Instead, it’s best to choose the appropriate cutting tool based on the specific type and size of screw.

So, if you’re ever unsure about whether your wire cutters can cut a particular screw, it’s always best to err on the side of caution and use a different cutting tool that has the necessary strength and durability to get the job done properly.

Different Shapes and Sizes

Screws come in many different shapes and sizes, each designed for a specific purpose. The most common types include wood screws, machine screws, and sheet metal screws. Wood screws are used for joining two pieces of wood and typically have a sharp point and coarse threads for a secure grip.

Machine screws are used in machinery and electronics and have a finer thread and flat or rounded head. Sheet metal screws are used for metal-to-metal connections and have a sharp point and threads that extend to the head. Other types of screws include lag screws, which are used for heavy-duty projects, and self-tapping screws, which create threads as they are screwed in.

It’s important to choose the right type of screw for your project to ensure a strong and secure hold.

Material and Hardness

Screws When it comes to screws, there are numerous types to choose from, each with their own unique advantages and disadvantages. One important aspect to consider when selecting screws is the material they are made from. Common materials include steel, aluminum, and titanium.

Steel is the most widely used material due to its strength and affordability. However, if corrosion is a concern, aluminum or titanium may be a better option as they are much more resistant to rust. Another crucial factor is the hardness of the screw.

Hardness often correlates with strength, so harder screws are generally stronger and more durable. However, they can also be more difficult to install and may cause damage to the material being screwed into if not carefully chosen. It’s important to consider both the material and hardness of screws when making your selection to ensure the best fit for your project.

The Importance of Proper Cutting Tools

When it comes to construction and DIY projects, choosing the right screws is crucial to ensure the durability and stability of your creation. Different types of screws are designed for different purposes and materials. For example, wood screws are ideal for attaching wood pieces, whereas a machine screw is designed for metal applications.

Sheet metal screws have sharp points and are used for attaching thin metal sheets. Self-tapping screws create their own threads and are ideal for attaching materials that don’t already have threads. The type of screw you choose also needs to match the head style you need, such as a slotted head or a Phillips head.

Choosing the wrong screw can lead to a weak connection and potentially cause your project to fail. So be sure to choose the right screw for the job, to keep your construction project strong and long-lasting.

Cutting Screws with Wire Cutters

Wire cutters are a versatile tool that can be used for a range of tasks, from cutting wires to snipping off nails and screws. But can wire cutters cut screws? The answer is yes, but with a few caveats. While wire cutters can technically cut through screws, it’s not always the best option.

For one, wire cutters are designed to cut through soft materials like wires, and may struggle with harder materials like screws. Additionally, wire cutters can dull quickly when used to cut through screws, which can make them less effective over time. If you need to cut screws, it’s usually best to use a specialized tool like a hacksaw or angle grinder.

However, in a pinch, wire cutters can be a handy tool to have on hand for small screws or projects where the screw is easily accessible.

Factors to Consider

Cutting screws with wire cutters may seem like a simple task, but it requires some considerations to ensure its success. First and foremost, it is essential to use the right type of wire cutters for the job. Opt for diagonal cutters as they are designed to cut through hard and thicker materials.

However, be mindful of the width of the screw head and the length of the cutter’s blades as using the wrong tool and size may damage both the screw and the cutter. Secondly, always wear protective gloves to avoid any injuries from the sharp cut edges of the screw. Finally, use enough pressure when cutting the screw to ensure a clean and precise cut.

Remember not to force the cutters, as this may cause them to break or malfunction. Overall, cutting screws with wire cutters can be done effectively with the right tools, technique, and safety measures.

Step-by-Step Guide

Wire Cutters Cutting screws with wire cutters can be a simple and effective way to shorten screws to the desired length. It’s important to select the proper wire cutters for the job, making sure they have strong, sharp blades that can cleanly cut through the screw. When cutting screws, it’s best to secure the screw in a vice or using pliers to keep it steady during the cutting process.

Place the wire cutters at the point where the screw needs to be cut and apply pressure to create a clean cut. Additionally, it’s important to file the cut end of the screw to eliminate any burrs or sharp edges that could cause injury. Using wire cutters to cut screws is an efficient and cost-effective solution for any DIY project or home repair.

Remember to always wear protective gloves and eyewear when working with wire cutters to ensure safety.

Conclusion

In the immortal words of Abraham Lincoln, “you can’t hammer a nail with a screwdriver.” Similarly, wire cutters are not designed to cut screws. So while you may be able to force them through with brute strength and determination, it’s best to stick to using the right tools for the job.

After all, you wouldn’t try to open a bottle of wine with a chainsaw, would you?”

FAQs

Can wire cutters cut screws?

No, wire cutters are not designed to cut screws. They are only meant for cutting wires.

What tool is best for cutting screws?

A hacksaw or a rotary tool with a cutting wheel is the best tool for cutting screws.

Can bolt cutters cut screws?

Yes, bolt cutters can cut screws as they are designed to cut through hard materials.

How do you remove a screw that is too long?

You can use a hacksaw to cut off the extra length of the screw. Alternatively, you can use pliers to bend the end of the screw and break it off.

Can a Dremel tool cut screws?

Yes, a Dremel tool with a cutting wheel can easily cut through screws.

Can scissors cut screws?

No, scissors are not strong enough to cut through screws.

How do you cut screws without damaging the material around them?

You can use a protective material like tape or a piece of cardboard around the area where you want to cut the screw to prevent any damage. You can also use a cutting wheel with a rotary tool to make precise cuts without damaging the surrounding material.