How to Remove a Broken Brake Bleeder Valve: Tips and Tricks for Easy Removal

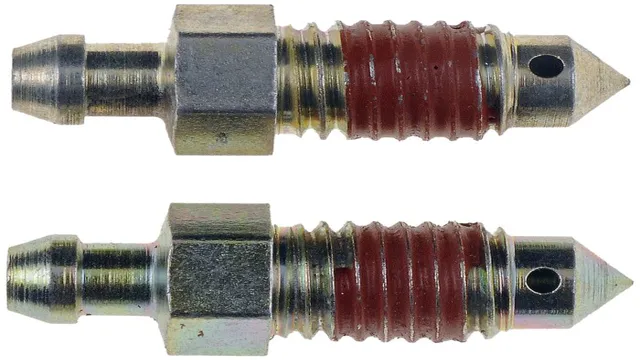

If you are a car owner, you know how important the brake system is when it comes to driving safely. However, even if you are thorough with maintenance, sometimes things might still go wrong, such as a broken brake bleeder valve. Brake bleeder valves are crucial components that facilitate the removal of air from the brake fluid, which helps to maintain the brake system’s efficiency.

A broken valve can lead to brake failure, which can be potentially dangerous. In this scenario, it is essential to know how to remove a broken brake bleeder valve properly. Don’t worry; we’ve got you covered!

Assess the Damage

If you’re dealing with a broken brake bleeder valve, assess the damage before attempting to remove it. Start by determining if the valve is completely broken or just the screw portion. If it’s just the screw, you can replace it with a new bleeder valve screw.

However, if the valve is completely broken, you’ll need to extract the remaining piece from the caliper or wheel cylinder. This can be done using a special tool called an extraction kit. The kit will allow you to remove the remaining portion of the valve without causing any further damage.

It’s important to approach this task with care to avoid damaging the surrounding components. Remember, safety should be your top priority when working on your vehicle’s braking system. Don’t hesitate to seek the help of a professional if you’re not confident in your abilities.

Check the Surrounding Components

When conducting an assessment of the damage to your electronic device, it’s important to check the surrounding components as well. For example, if you dropped your phone and cracked the screen, it’s possible that the internal components could also be damaged. Make sure to inspect the edges and corners of your device for any signs of impact or deformation.

You should also test all the functionalities of the device, such as the camera, speakers, and microphone, to ensure that they are all working correctly. It’s important to assess the overall condition of the device before deciding on any repairs or replacement. By doing so, you can prevent further damage and make informed decisions on how to proceed.

Don’t overlook the surrounding components, as they could also be contributing to the problem.

Inspect the Valve

When assessing valve damage, the first step is to inspect the valve thoroughly. Start by examining the surface for signs of corrosion, abrasion, cracks, or leaks. Then, check the valve body, stem, disc, and seat for any signs of wear and tear.

It’s crucial to be thorough in your assessment as any damage to a valve can lead to significant problems down the line. Look for signs of misalignment or distortion in the valve, as these can also cause problems. If you suspect any damage, take action immediately and address the issue before it worsens.

By assessing the damage to your valve early on, you can make timely repairs and avoid costly and hazardous consequences in the future. Remember, the key to ensuring the longevity and optimal performance of your valves is regular maintenance, inspection, and timely repairs.

Gather Necessary Tools

If you want to remove a broken brake bleeder valve, the first step is to gather all the necessary tools. You’ll need a few things to make the job easier and hopefully avoid further damage to your vehicle. Some of the tools you’ll need include a wrench set, a penetrating oil, a hammer, and a drill with a bit the size of your bleeder valve.

Once you have all the tools, it’s important to start by using a penetrating oil to soak the area around the bleeder valve. This will help to loosen any rust or debris that may have accumulated over time and make it easier to remove the valve. Now that you have everything you need and the area is sufficiently lubricated, it’s time to start removing the broken valve.

First, use a wrench to try to turn the valve counterclockwise. If that doesn’t work, try tapping it gently with a hammer to see if it will break loose. If it still won’t turn, you may need to drill a small hole in the center of the valve to loosen it.

Once you’ve drilled the hole, you should be able to use pliers or a wrench to turn the valve and remove it from the brake line. Remember to take your time and work carefully when removing a broken brake bleeder valve. This is a delicate job that requires patience and attention to detail.

If you’re not confident in your abilities, it’s always best to seek professional help from a mechanic or auto body specialist. With the right tools and approach, however, you can remove a broken brake bleeder valve and get your vehicle back on the road in no time.

Pliers

When it comes to using pliers for a project, it’s important to gather the necessary tools to ensure success. Of course, you’ll need a pair of pliers, but there are other items that can come in handy as well. Depending on the project, wire cutters, a ruler or measuring tape, and a marker or pencil may be necessary.

It’s also important to have a sturdy work surface and proper lighting to ensure safety and accuracy. Taking the time to gather these tools will make the process smoother and more efficient. Remember, having the right tools for the job is essential to getting the results you want.

Vise-Grip

When it comes to using a vise-grip, it’s important to gather the necessary tools before getting started. Of course, you’ll need a vise-grip, but you’ll also want to make sure you have a pair of gloves to protect your hands, especially if you’re working with metal. Additionally, you may need a few other tools, depending on the specific task at hand.

For example, if you’re using a vise-grip to remove a stubborn bolt, you might need a socket set or a wrench to help you turn it. Alternatively, if you’re using a vise-grip to hold a piece of wood while you drill, you might need a drill bit and drill. Whatever tools you need, make sure you gather them all before starting your project.

This will help you work more efficiently and effectively, and reduce your risk of injury. So, take the time to gather your tools and prepare yourself properly, so you can tackle your vise-grip project with confidence.

Drill Bits

When it comes to drilling, having the right tools is crucial for getting the job done efficiently and effectively. One of the most important tools in any drill kit are drill bits. These cylindrical cutting tools are designed to create holes in a variety of materials, from wood and metal to plastic and concrete.

To gather the necessary drill bits for your projects, it’s important to determine the size and type of holes you’ll be drilling. This will help you choose the best bits for the job. Some common types include twist, spade, and auger drill bits.

Each of these bits is designed to work with specific materials and hole sizes, so it’s important to choose the right ones to avoid making mistakes or damaging your materials. By taking the time to gather the necessary drill bits for your project, you’ll be able to work with precision and confidence, knowing your tools are up to the task.

Extractor Kit

If you’re planning on making your own essential oils at home, you’ll need an extractor kit. But what tools are necessary for this process? First and foremost, you’ll need a distiller. This is the most important tool in your kit, as it’s what will extract the essential oils from the plant material.

You’ll also need a hydrosol collector, which collects the water that comes out of the distiller. Other tools you might need include a thermometer, a strainer or cheesecloth, a funnel, and storage bottles for your finished product. It’s important to gather all of the necessary tools before you begin, as this will save you time and frustration later on.

With your extractor kit fully stocked, you’ll be on your way to creating high-quality essential oils in no time.

Prepare Your Workspace

Removing a broken brake bleeder valve can feel like a daunting task, but with the right preparation, you can tackle the job with confidence. The first step is to gather all the necessary tools and materials. You’ll need a set of pliers or a wrench, a penetrating oil, a drill, a tap and die set, and a new brake bleeder valve.

Once you have everything ready, it’s essential to create a workspace that is clean and well-lit. Find a flat surface where you can easily access your vehicle’s brake system and protect the surrounding area with a drop cloth or cardboard. It’s also a good idea to wear protective gear like gloves and safety glasses to reduce the risk of injury.

By taking the time to prepare your workspace, you’ll be able to focus on the task at hand and have everything you need within reach to successfully remove the broken brake bleeder valve and replace it with a new one.

Jack up the Car

Before jack up your car, you need to prepare your workspace for the job. It’s important to start by choosing a flat and level location for your car. You don’t want it to roll away or shift while you’re working on it.

Once you’ve found the perfect spot, make sure there’s nothing around that could get in your way. If you have to work on a busy street, put up cones or other warning signs to let others know you’re working there. You should also clear any debris away from the area, as you wouldn’t want to trip or fall while working.

Now it’s time to gather all the equipment that you’ll need for the job, including the jack, jack stands, and lug wrench. Make sure that all your equipment is in proper working order, and that it’s in good condition before you start using it. Check that the jack stands are sturdy and won’t collapse under your car’s weight.

You don’t want to get under the car and have the jack stands fail on you, which could be disastrous. When you’re setting up for the job, always remember to put safety first. Even if it takes a little longer to prepare, it’s worth it to avoid accidents and injury.

Double-check everything before you begin jacking up your car, and never cut corners or take risks with your safety or the safety of others. Overall, preparing your workspace is a crucial step in jacking up your car. You want to choose a safe, level location, gather all the necessary equipment, and make sure that everything is in good working order.

By being careful and taking the time to prepare properly, you can avoid accidents and complete the job safely.

Remove Tire and Wheel

When it comes to removing a tire and wheel, the first thing you need to do is prepare your workspace. This means finding a flat and level surface to work on, such as a garage floor or a paved driveway. Make sure the area is well-lit and free from any debris, as this will help to prevent accidents and make the process easier.

It’s also important to gather all the necessary tools and equipment before you begin, such as a lug wrench and jack. Keep in mind that this process can be quite physically demanding, so it’s important to take breaks and stay hydrated throughout. By taking the time to prepare your workspace, you’ll be able to remove your tire and wheel safely and efficiently, without any unnecessary complications.

Remove the Broken Valve

Removing a broken brake bleeder valve can be a tricky process, but with the right tools and some patience, it can be done. Begin by soaking the valve in penetrating oil to help loosen it up. Then, use a wrench or needle-nose pliers to try and twist the valve counterclockwise.

If it still won’t budge, try tapping it gently with a hammer to free it up. If all else fails, you may need to use a specialized tool called an easy out to extract the valve from the caliper. Be sure to take your time and not force anything, as breaking off any part of the valve in the caliper can lead to more costly repairs.

With a little perseverance and the right tools, however, you should be able to successfully remove the broken brake bleeder valve and get back on the road.

Apply Penetrating Oil

When it comes to removing a broken valve, one of the first things you can try is applying penetrating oil. This type of oil is designed to seep into small spaces and loosen up any rust or debris that may be causing the valve to stick. To apply, simply spray or drip the oil onto the stuck valve and let it sit for a few minutes.

Then, try turning the valve with pliers or a wrench. If it still won’t budge, you may need to repeat the process a few times or try a different method. Remember, patience is key when it comes to removing a broken valve.

Rushing the process could cause even more damage and make the situation worse. By taking your time and using the right tools and techniques, you can successfully remove a broken valve and get back to your regular plumbing routine in no time.

Use Pliers to Loosen Valve

If you find yourself with a broken valve, the first step to removing it is to loosen it with pliers. This can be a bit tricky, as the valve can be tightly in place. The key is to use the right amount of pressure – too much, and you risk damaging the surrounding area.

Start by using the pliers to grip the valve as tightly as possible. Then, gently turn it back and forth, using a small amount of force. With some persistence, the valve should start to loosen up.

Once it’s loose enough, you can then remove it completely using your hands or a wrench. Remember to be careful throughout the process, and don’t hesitate to call in a professional if you need extra help. By removing the broken valve carefully and responsibly, you can ensure the continued smooth functioning of your plumbing system.

Use Vise-Grip for Added Torque

When it comes to fixing your car, there are few things more frustrating than a broken valve. Fortunately, with the right tools and techniques, you can remove a broken valve without too much trouble. One tool you should definitely have on hand is a Vise-Grip.

This handy tool will give you the extra torque you need to twist the valve free. Simply use the Vise-Grip to clamp onto the broken valve, and then apply pressure as you turn it counterclockwise. With the added grip strength, you should be able to free the broken valve easily.

Of course, it’s important to make sure you have a replacement valve before you start working. As long as you have the right parts and tools, though, removing a broken valve is a manageable task. Just stay calm, take your time, and use the Vise-Grip to your advantage.

Your car will be back up and running smoothly in no time!

Drill a Small Hole in the Center of the Valve

If you have a broken valve that needs removal, you can start by drilling a small hole in the center of the valve. This hole serves as a guide for the extraction process and should be just enough to fit a screw extractor. To do this, first, clamp down the broken valve securely using a pair of pliers or a vice grip.

Take a drill with a small drill bit and center it over the top of the valve, creating a small guide hole. Be careful not to drill too deep, or you may damage the surrounding area. Once you have a guide hole, take a screw extractor that is slightly larger than your guide hole and place it into the hole.

Firmly tap the extractor handle with a hammer until it is securely attached to the broken valve. Slowly turn the extractor counterclockwise to loosen and remove the valve. You may encounter resistance, so practice patience and continue to turn the extractor until the valve breaks free.

It’s important to note that if the valve continues to resist removal, applying heat using a torch or heat gun can help loosen the valve and make the removal process easier. By drilling a small hole in the center of the valve and using a screw extractor, you can remove a broken valve without causing further damage to the surrounding area. Remember to take your time, be patient, and wear protective gear when working with tools.

Use Extractor Kit to Remove Valve

If you’re dealing with a broken valve, an extractor kit can come in handy to remove it. Broken valves can cause significant damage if not dealt with promptly, so it’s essential to address the issue as soon as possible. First, you’ll need to gather the necessary tools, including an extractor kit, safety glasses, and gloves, then turn off the water supply to the area.

Next, you’ll need to remove the cap of the broken valve and insert the extractor tool into the valve body. Turn the extractor counterclockwise until it reaches the bottom of the broken valve, then continue to turn it until the valve is entirely removed. If you encounter any resistance, be sure to stop and regroup before proceeding.

After removing the valve, inspect the surrounding area for any damage, and replace the valve with a new one. Using an extractor kit can make the process of removing a broken valve significantly easier and safer, allowing you to address the issue promptly and without causing additional damage.

Replace the Valve

If you’re experiencing difficulty removing a broken brake bleeder valve, no need to fret because this is a common issue that mechanics encounter. One of the safest and most reliable ways to remedy this situation is to replace the valve altogether. To begin the process, you’ll need a valve replacement kit, a wrench, and some penetrating fluid like WD-40.

Firstly, you’ll want to completely drain the brake fluid reservoir, so it doesn’t leak out during the replacement process. Afterward, you can apply the penetrating fluid on the valve to help loosen it and then use the wrench to unscrew both the broken valve and the surrounding nut. Once you’ve removed them, it’s time to install the new valve while being careful not to over-tighten it.

Finally, don’t forget to refill the reservoir with the correct amount of brake fluid and bleed the brake lines to clear any air pockets. By following these steps, you can easily replace your broken brake bleeder valve and get back on the road in no time.

Install New Valve

When it comes to fixing plumbing issues in your home, changing a valve can be a relatively simple but important task. Before you begin, make sure to turn off the water supply and drain any standing water in the pipes. Then, you’ll want to remove the old valve by loosening the nuts and taking it off the pipe.

Next, clean the pipe and replace any old or damaged parts. Finally, attach the new valve onto the pipe and tighten the nuts, making sure everything is secure and leak-free. It’s important to choose the right size and type of valve for your specific plumbing needs.

Remember, taking the time to replace a faulty valve can prevent costly water damage and ensure the longevity of your plumbing system.

Bleed the Brake System

If you’re experiencing spongy brakes, one possible culprit could be a faulty valve. In such cases, replacing the valve might be necessary for restoring your car’s braking system to its optimum functionality. To replace the valve, you first need to bleed the brake system, which entails removing any air bubbles that have accumulated in the system.

Start by connecting a tube to the brake bleeder valve and placing the other end in a container of brake fluid. Then, pump the brake pedal several times until clean brake fluid starts coming out of the bleeder valve, indicating that all the air has been purged from the system. Once the brake system has been bled, you can proceed to replace the valve by first disconnecting the brake line from the valve and then using a wrench to unscrew the valve and remove it from the brake assembly.

Be sure to install the new valve securely, connect the brake line, and refill the brake fluid before testing your brakes to ensure they’re working properly. By replacing a faulty valve and bleeding your brake system, you can improve your car’s stopping power and ensure a safer driving experience.

Conclusion

It may seem like a daunting task to remove a broken brake bleeder valve, but with the right tools and a little patience, it’s definitely doable. Just like any problem in life, sometimes it takes a little extra effort to fix things that seem broken beyond repair. So roll up your sleeves, grab some PB blaster and a pair of vice grips, and show that broken brake bleeder valve who’s boss!”

FAQs

What happens if a broken brake bleeder valve is not replaced?

If a broken brake bleeder valve is not replaced, air may enter the brake system, compromising brake performance and potentially leading to dangerous situations on the road.

Can a broken brake bleeder valve be repaired?

Typically, a broken brake bleeder valve cannot be repaired and must be replaced entirely to restore proper brake function.

How can I tell if my brake bleeder valve is broken?

Signs of a broken brake bleeder valve may include a spongy or soft brake pedal, decreased braking power, or visible leaks around the valve.

Can I remove a broken brake bleeder valve myself, or should I seek professional help?

It is recommended to seek professional help when removing a broken brake bleeder valve, as the process can be tricky and potentially cause further damage to the brake system if not done correctly.

How long does it usually take to replace a broken brake bleeder valve?

The length of time it takes to replace a broken brake bleeder valve can vary depending on the make and model of your vehicle and the severity of the issue. However, it typically takes between 1-2 hours.

What materials do I need to replace a broken brake bleeder valve?

Some materials you may need to replace a broken brake bleeder valve include a new valve, a brake bleeder wrench, a flare nut wrench, and brake fluid.

Can I drive with a broken brake bleeder valve?

It is not safe to drive with a broken brake bleeder valve, as doing so can cause a loss of brake function and potentially lead to accidents or injury on the road.