So you’re ready to install a 220-volt outlet in your home, but you’re not sure what wire to use. Choosing the right wire is crucial for safety, performance, and longevity of your electrical system. It can seem overwhelming with all the options available and technical specifications to consider.

But don’t worry, we’ve got you covered! In this blog post, we’ll help you navigate the process of selecting the appropriate wire for your 220 outlet, so you can power your heavy-duty appliances with confidence. Let’s dive in!

Understanding electrical codes

When it comes to installing a 220 outlet, choosing the right type of wire is crucial. Generally, you will need to use a 10-gauge or 12-gauge wire, depending on the specific requirements of the electrical code in your area. The wire should be made of copper, as it is a reliable and efficient conductor of electricity.

It is important to note that using aluminum wire for a 220 outlet is not recommended, as it can lead to issues such as overheating and corrosion. Additionally, it is essential to ensure that the wire is rated for the correct voltage and amperage, as using wire that is not rated appropriately can also pose dangerous risks. Keep in mind that consulting with a licensed electrician is always recommended before attempting any electrical work to ensure you are meeting all applicable codes and safety standards.

What is a 220 outlet?

A 220 outlet is a type of electrical outlet that is capable of handling higher voltage than a standard outlet. The term “220” refers to the voltage level, which is typically used to power heavy-duty appliances such as washing machines, dryers, and air conditioners. Understanding electrical codes is essential when dealing with a 220 outlet because they are subject to specific safety requirements and installation guidelines.

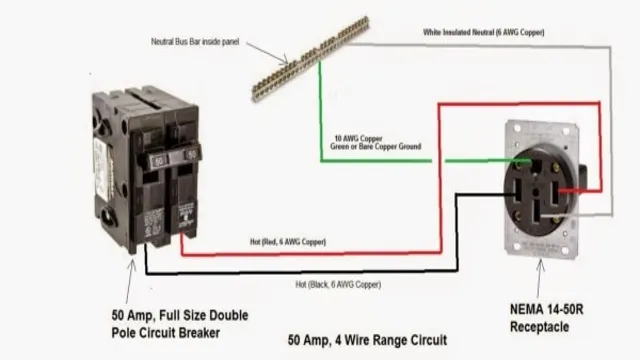

For instance, a 220 outlet must be wired with thicker gauge wires and protected by dedicated circuit breakers to prevent overloading and electrical fires. It’s essential to hire a licensed electrician to install a 220 outlet to ensure that it’s done safely and correctly. By following electrical codes and guidelines, you can ensure that your 220 outlet functions correctly and safely, providing reliable power for your high-voltage appliances.

Electrical codes and safety requirements

Electrical codes play a critical role in ensuring safety when working with electricity. These codes provide a set of rules, standards, and guidelines that must be followed when installing, repairing, and maintaining electrical systems. The ultimate goal of these codes is to protect people and property from the dangers of electricity.

Electrical codes cover various aspects of electrical work, including the types of materials that can be used, the methods of installation, and the spacing of wires and cables. One of the most critical aspects of electrical codes is the requirement for grounding. Grounding helps to prevent electrical shocks by providing a safe path for electric current to follow in an emergency.

To stay up-to-date with electrical codes, it is essential to have a good understanding of the latest rules and regulations. Whether you are a professional electrician or a DIY enthusiast, taking the time to learn about electrical codes is an investment in your safety and the safety of those around you.

Selecting the correct wire type

When it comes to the question of what type of wire for a 220 outlet, there is no one-size-fits-all answer. The wire type you choose will depend on a variety of factors, including the amperage needed for your application and the distance the wire needs to travel. For example, if you need to power a high-amperage appliance like an electric water heater or air conditioner, you will likely need a larger gauge wire to handle the current.

Similarly, if your outlet is located far away from your electrical panel, you may need a thicker wire to compensate for voltage drop over distance. It’s also important to check local codes and regulations to make sure you select a wire type that is approved for use in your area. Overall, choosing the correct wire type is a critical part of ensuring a safe and reliable 220 outlet installation.

Wire size and amperage requirements

When it comes to wiring your electrical system, selecting the correct wire type is crucial to ensuring safety and preventing electrical fires. One important factor to consider is wire size and amperage requirements. The wire size you need will depend on the amperage of the circuit.

Using a wire that is too small for the amperage can cause overheating and potentially a fire. It’s essential to understand the electrical load of your system and choose a wire that can handle that load safely. Copper wire is a common option for most applications due to its excellent conductivity and durability.

However, it’s important to note that different types of wire may be required for different situations. For example, if you’re wiring a car, you may need to use a specific type of wire that is designed to handle vibrations and other harsh conditions. Always consult with an electrician or an expert in electrical wiring to ensure you choose the right wire for your specific needs.

Copper vs aluminum wires

When selecting the correct wire type for your electrical project, one crucial factor to consider is whether to use copper or aluminum wiring. Copper wiring has been the standard material for electrical wiring for decades due to its conductivity and durability, but aluminum wiring is also an option that can be cost-effective. However, it’s important to keep in mind that aluminum wiring is more vulnerable to corrosion and overheating issues, which can lead to electrical fires.

Copper wiring, on the other hand, has a lower risk of these issues but is generally more expensive. Ultimately, the decision between copper and aluminum wiring will depend on your specific project needs and budget. It’s always important to consult with an expert electrician or electrical engineer to ensure that you’re using the right wire type for your specific application.

Types of wiring insulation

When it comes to wiring, selecting the correct wire type is crucial. There are various types of wiring insulation available, each with its own unique set of properties and capabilities. The most common type of insulation is PVC, which is widely used due to its low cost and high durability.

It’s also resistant to moisture, chemicals, and abrasion, making it ideal for many applications. On the other hand, if you require a wire that can withstand extreme temperatures, Teflon insulation may be the best choice. Teflon also has high resistance to chemicals and is non-flammable.

Another type of insulation is rubber, which is ideal for wires that are exposed to mechanical stress. It’s also heat resistant and withstands exposure to oils and solvents. When selecting wire insulation, it’s also important to consider the wire’s intended use and environment.

Ultimately, choosing the correct wire insulation is crucial to ensure the safe, reliable, and efficient operation of your electrical systems.

Installation process

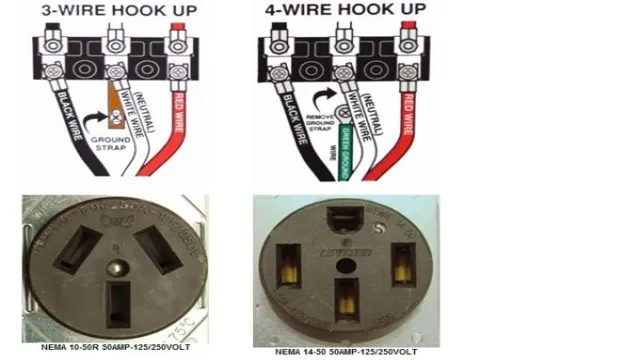

If you’re installing a 220-volt outlet, it’s important to use the right type of wire. The most common type of wire used for a 220 outlet is 10/3 cable, which consists of three wires and a ground wire. This cable is capable of carrying up to 30 amps of current, which is what you’ll need for most appliances that require a 220-volt outlet.

The wire you use should also be rated for 600 volts to ensure it can handle the voltage safely. It’s important to follow all local building codes and regulations when installing a 220-volt outlet, and if you’re not comfortable doing it yourself, it’s best to hire a licensed electrician. By using the right type of wire and following the proper installation process, you can ensure that your 220-volt outlet is safe and effective for all your electrical needs.

Tools and materials needed

When it comes to installing a new flooring option in your home or office, there are a few tools and materials you will need to get the job done right. First, you will need a measuring tape to determine the size of the area you wish to cover with your new flooring. You will also need a utility knife and a straight edge for cutting the flooring to size.

If you plan on installing hardwood flooring, you will need a nail gun, and if you opt for tile flooring, you will need a tile cutter. In addition to these tools, you will need a pry bar, a hammer, a knee pad, and safety glasses to ensure safety during the installation process. Once you have all the necessary tools and materials, you can begin the installation process.

The first step is to remove any existing flooring and prepare the subfloor for the new flooring. This may involve sanding, sweeping, or filling any cracks or holes in the subfloor. Next, you will need to lay down an underlayment to provide a smooth surface for the flooring to rest on.

After the underlayment is in place, you can begin laying down the new flooring. It’s best to start in one corner of the room and work your way across, using spacers to ensure a consistent gap between planks or tiles. As you go, trim any pieces that need to fit around doorways or other obstacles using your utility knife and straight edge.

Once the flooring is in place, you can add any finishing touches such as baseboards or trim. With proper installation, your new flooring will be a beautiful and functional addition to your home or office for years to come.

Step-by-step instructions

When it comes to installing a new software, web application, or even a plugin, the process can seem daunting if you don’t know where to begin. Fortunately, many installation processes are straightforward and easy to follow. To get started, the first step is to download the installation files from the provider’s website.

Once the download is complete, locate the downloaded file and double-click on it to begin the installation process. Follow the on-screen instructions carefully, making sure to select the appropriate options as you go. Depending on the software, you may need to choose the installation location, agree to terms and conditions, or customize settings.

Once the installation is complete, you may need to restart your computer or web browser for the changes to take effect. With these simple steps, you’ll be well on your way to installing new software and enjoying its benefits in no time!

Final thoughts and safety tips

When setting up a 220 outlet, it’s important to choose the right wire to ensure safety and efficiency. The type of wire you use will depend on the amperage required by your appliance. For example, a 30-amp appliance will need 10-gauge wire, while a 50-amp appliance will require 6-gauge wire.

It’s important to consult an electrician or reference a wire sizing chart to ensure you select the correct wire. Additionally, be sure to use a proper conduit for the wire, and always turn off the power when performing any electrical work. Taking these precautions will help ensure the safety of you and your home.

Conclusion

So, there you have it – the answer to the age-old question of what type of wire to use for a 220 outlet. And though it may seem obvious to some, it’s always best to heed the sage advice of a qualified electrician to ensure a safe and efficient electrical setup. After all, as they say, it’s better to be wired for safety than sorry!”

FAQs

What type of wire should be used for a 220 outlet?

A 10-gauge copper wire with a black, red, and green conductor should be used for a 220 outlet.

Can I use a lower gauge wire for a 220 outlet?

No, using a lower gauge wire can be dangerous and lead to wire overheating and potential electrical fires.

Can I use aluminum wire for a 220 outlet?

It is not recommended to use aluminum wire for a 220 outlet as it has a lower capacity for carrying electrical current and can lead to overheating.

Can I use a 3-conductor wire for a 220 outlet?

Yes, a 3-conductor wire with black, white, and green conductors can be used for a 220 outlet as long as it is a 120/240-volt outlet and not a 120/208-volt outlet.

What is the maximum distance between a 220 outlet and the circuit breaker?

The maximum distance between a 220 outlet and the circuit breaker varies depending on the wire gauge. For a 10-gauge wire, the maximum distance is approximately 30-40 feet.

Can I use a 220 outlet for a dryer?

Yes, a 220 outlet is typically used for dryer installations.

Do I need a special outlet for a 220v welder?

Yes, a special 220v outlet, typically a NEMA 6-50 outlet, is required for a welder installation.