If you’re planning to build something using 2x4s, one of the most important things to consider is finding the right screws. The right screws can make the difference between a sturdy, long-lasting creation and one that falls apart at the slightest touch. But with so many types of screws on the market, how do you know which ones to choose? It can be overwhelming to try and navigate the different options and find the ones that will work best for your project.

Luckily, we’ve got you covered. In this blog, we’ll break down the different types of screws available and help you find the perfect ones for your 2×4 project. From flathead to roundhead, self-tapping to lag bolts, we’ve got all the information you need to make an informed decision.

So let’s get started and find the right screws for your next project!

Understanding Screw Lengths

When it comes to building with 2x4s, it’s important to choose the right screw length to ensure a strong and secure structure. Generally, the ideal screw length for a 2×4 is around 2 1/2 inches to 3 inches long. This length is long enough to provide good gripping power, but not so long that it will poke through the other side of the board or damage the wood.

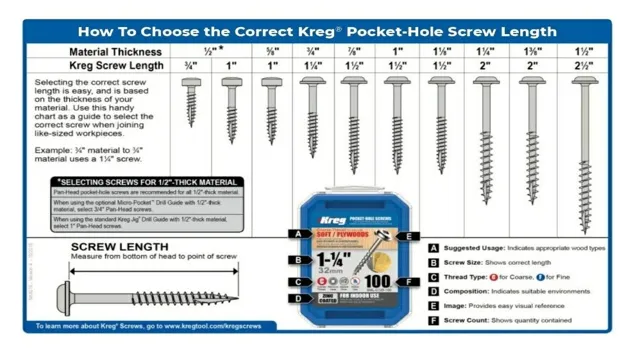

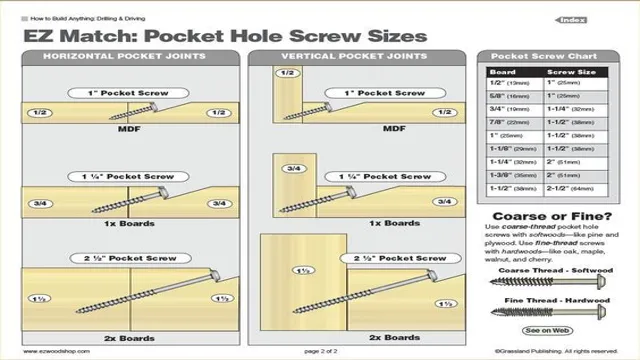

Remember that the length of the screw can also vary depending on the type of wood you’re using, the thickness of your boards, and the overall weight your structure will need to support. If you’re still unsure about the ideal screw length, it’s always a good idea to consult with a professional or reference a screw sizing chart to avoid any costly mistakes or safety hazards.

Standard Screw Lengths

When it comes to screws, understanding the different lengths available is crucial for any project. Standard screw lengths can vary depending on the type of screw and its intended use. For example, interior wood screws come in lengths from 1 inch to 3 inches, while exterior wood screws can range from 1 5/8 inches to 6 inches.

It’s important to choose the right length for your project to ensure that the screw is securely holding the material in place. Using a screw that is too short can result in loose or wobbly connections, while using a screw that is too long can damage the material or create a hazard. So, take the time to measure and choose the appropriate length for your screws to ensure a successful and safe project.

Recommended Length for 2x4s

When it comes to building with 2x4s, it’s essential to consider the recommended length for optimal structural integrity. The length of screws used is a crucial factor in determining the recommended length of the 2x4s. As a general rule of thumb, the screw length should be at least twice the thickness of the board being attached.

For example, for 2x4s with a thickness of 5 inches, the screw length should be at least 3 inches. This ensures that the screws penetrate deep enough to provide a secure hold and prevent the boards from pulling apart.

However, it’s also important to take into account the type of project you’re working on and the weight that it will hold. For heavier structures, longer screws and longer 2x4s may be necessary. Always follow manufacturer recommendations and consult with a professional if you have any doubts.

Factors to Consider

When it comes to using screws for a 2×4, there are several factors to consider. The length of the screw is crucial, as it needs to penetrate the 2×4 effectively without going too far or not far enough. Typically, a 2 1/2 inch to 3 inch screw is optimal for a 2x

However, it’s essential to also consider the type of screw, the material being attached to the 2×4, and the weight it needs to support. For example, if you’re attaching a heavy load to the 2×4, you may want to opt for a longer and sturdier screw. Conversely, if you’re attaching lightweight material, a shorter screw may suffice.

Ultimately, the best advice is to consult with a professional or reference a comprehensive screw chart to ensure you’re using the appropriate screw length while keeping safety and stability in mind.

Purpose of the Project

The purpose of any project is to achieve a specific goal or set of objectives within a given timeframe. However, there can be several factors that need to be considered before embarking on a project. The first factor is the scope of the project, which involves identifying the needs, requirements, and expectations of stakeholders.

The second factor is the available resources, including personnel, finances, equipment, and technology. The third factor is the feasibility of the project, which considers the risks, benefits, and constraints that could impact the project’s success. The fourth factor is the timeline and scheduling of tasks to ensure that the project is completed on time and within budget.

Finally, the fifth factor is the communication and collaboration among team members, stakeholders, and partners. By considering these factors, project managers can ensure that their projects are successful and deliver real value to their stakeholders.

Location of the Project

When it comes to real estate projects, choosing a location can make all the difference. There are several factors that developers should consider when deciding where to build their project. One important factor is the proximity to amenities and transportation.

Buyers are often looking for easy access to public transportation, as well as nearby grocery stores, restaurants, and other conveniences. Additionally, the local school district and crime rates can impact a buyer’s decision to invest. Developers should also consider the demographic they are targeting, with factors such as age, income, and lifestyle all impacting location preferences.

The cost of land and construction in the area should also be taken into account. Ultimately, choosing the right location can make a property more desirable and lead to better returns on investment.

Strength Requirements

When thinking about strength requirements, there are a few factors to consider. Firstly, the intended use of the material is crucial. Different applications will dictate different strength requirements.

For example, a material used in construction will need to have a higher strength than a material used in packaging. Additionally, environmental factors should be taken into account. Exposure to harsh conditions such as extreme temperatures or corrosive substances can weaken a material over time, so the strength requirements must factor in the material’s ability to withstand these conditions.

It’s also essential to consider the load-bearing capacity needed. The weight and pressure exerted on the material will determine the level of strength required. Ultimately, the strength requirements will depend on the specific application and conditions the material will be exposed to.

By understanding and considering these factors, the appropriate strength specifications can be established.

Choosing the Right Screws

When it comes to building with 2x4s, choosing the right screws can make all the difference. So, what length screws should you use for 2x4s? Generally, you’ll want to use screws that are at least 5 inches long to ensure a secure connection.

This will allow the screw to penetrate both pieces of wood, with enough length to hold steady and prevent any wobbling or shifting during use. However, if you plan on installing thicker or heavier items, such as cabinets or shelves, you may want to consider using 3-inch screws or longer to provide added stability. Remember, the length of your screws will depend on the specific project and the weight load it will be supporting, so be sure to do your research and select the right screws for the job.

Selecting Screw Lengths

When it comes to selecting screw lengths, there are a few factors to consider to ensure that you choose the right screw for your project. The most important factor is the thickness of the material you will be attaching. If the material is thin, the screw should be shorter, and if it’s thick, the screw should be longer.

It’s also important to consider the type of material you’ll be working with, as some materials, such as hardwood, require longer screws than softer materials like pine. Additionally, if you’re using screws to attach two pieces of material, make sure the length of the screw is long enough to penetrate both materials without poking out the other side. By taking these factors into consideration, you can choose the right screw length for your project and ensure that your finished product is secure and sturdy.

Matching Screw Diameter

When it comes to choosing the right screws for any project, one important consideration is the matching screw diameter. This is because using the wrong diameter screw can result in a lack of stability and security, and the screw may not be able to hold the weight or withstand the force it is intended to. To ensure that you are choosing the right diameter screw, you will want to measure the hole or opening where the screw will go and choose a screw with the same diameter as that measurement.

This will help ensure that the screw fits properly and is able to provide the necessary support and stability for your project. So, remember to carefully measure and match the screw diameter to the hole or opening, and you will be well on your way to choosing the right screws for your project.

Materials Used for the Screws

When it comes to choosing the right screws for your project, one of the most important factors to consider is the materials they are made of. There are various materials used to make screws, including stainless steel, carbon steel, brass, and aluminum. Each material has its pros and cons when it comes to strength, durability, and resistance to corrosion.

Stainless steel is the most popular choice as it provides excellent strength and corrosion resistance. Carbon steel is also a strong option, but it is more susceptible to rust and corrosion. Brass and aluminum are often used for specific projects that require non-magnetic or lightweight properties.

It’s important to carefully consider the specific needs of your project to make the best choice of screw material. By selecting the right screws, you can ensure the longevity and stability of your project.

Conclusion and Final Tips

In conclusion, determining the appropriate length of screws for your 2×4 project requires careful consideration and a solid understanding of the thickness and composition of the materials being used. Whether you are a seasoned carpenter or a novice DIY-er, remember the age-old adage: measure twice, screw once! And if all else fails, just wing it and hope for the best – after all, isn’t that how most home improvement projects go anyway?”

FAQs

Example:

What type of screw should I use for a 2×4 stud wall?

For a 2×4 stud wall, you should use #8 wood screws that are 2.5 inches long.

Can I use drywall screws for a 2×4 framing?

No, it is not recommended to use drywall screws for framing as they are not strong enough. Use wood screws instead.

How many screws do I need for a 2×4 stud?

Typically, you should use two screws per stud for securing it to the bottom plate and top plate.

What is the maximum length of a wood screw for a 2×4?

The maximum length of a wood screw for a 2×4 is 3 inches.

Can I use decking screws for a 2×4 framing?

Yes, you can use decking screws for a 2×4 framing. However, make sure they are long enough and have the appropriate thread pattern.

Can I use screws instead of nails for framing?

Yes, you can use screws instead of nails for framing. However, make sure they are long enough and have the required tensile strength.

What is the recommended spacing between screws for a 2×4 stud?

The recommended spacing between screws for a 2×4 stud is 12 inches on center.