Laser welding machines have revolutionized the welding industry, overlapping traditional welding methods. This innovative technology has shown significant growth in applications across several industries, including automotive, aerospace, medical, and many more. Laser welding machines join two or more metal parts with incredible accuracy, speed, and efficiency, resulting in welds with zero defects.

Want to know more about laser welding machines? This blog post will give you every detail you need to know, from the basics to the advanced technology that makes laser welding machines a game-changer in the welding industry. So, let’s dive right into it!

What is Laser Welding?

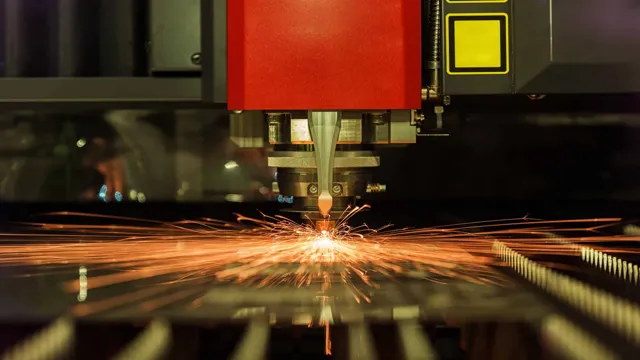

If you’re wondering what a laser welding machine is, it’s a state-of-the-art equipment utilized in many manufacturing industries. Laser welding is a technique that joins materials by heating them to the point of fusion with a laser. Unlike traditional welding methods, laser welding offers many additional advantages such as precision, speed, and versatility.

The laser beam can be directed precisely at the point of welding, which reduces the amount of heat generated and makes it possible to weld small and complex workpieces without damaging other parts of the objects. Additionally, the laser welds at high speeds, and it produces high-quality joints with minimal distortion and porosity. Laser welding machines are frequently employed in the production of electronic devices, automotive parts, and aerospace components, among other things.

If you need a fast, efficient method for welding applications, then a laser welding machine might be a perfect solution for your business.

Defining Laser Welding

Laser welding is a process of joining two materials using a concentrated beam of high energy light. The laser beam melts the surface of the materials, causing them to fuse together. This type of welding is typically used for precise and small welds, as it allows for greater control and accuracy than traditional welding methods.

Laser welding is commonly used in the manufacturing of electronic devices, medical equipment, and even jewelry. One major benefit of laser welding is that it creates a minimal amount of heat-affected zones, reducing the risk of damage to the surrounding materials. So if you’re looking for a precise and efficient welding method, laser welding may be the perfect solution for you.

How Does Laser Welding Work?

Laser welding is a process of joining two materials together using a focused beam of high-powered laser light. The laser beam generates intense heat, which melts the material and fuses the pieces together. The process is highly precise and is commonly used in the manufacturing industry for bonding metals and plastics.

In laser welding, the laser beam is directed onto the surface of the material to be welded. The beam then melts the material, creating a molten pool that cools and solidifies to form a joint. The key advantage of laser welding is its ability to create a strong, permanent bond without the need for additional materials such as rivets or adhesives.

Due to the precision and speed of the laser, it is possible to achieve very small welds in very precise locations on a component. This makes laser welding ideal for applications where accuracy and consistency are essential, such as in the aerospace and medical device industries.

Types of Laser Welding Machines

If you’re wondering what a laser welding machine is, it’s a device that uses a high-powered laser beam to fuse two materials together. There are several types of laser welding machines, including solid state, fiber, CO2, and pulsed laser welding machines, with each type designed for specific welding applications. Solid state laser welding machines are known for their precision and typically found in the medical industry.

Fiber laser welding machines are perfect for joining materials like steel and aluminum, while CO2 laser welding machines are ideal for industrial welding jobs. Pulsed laser welding machines provide the right amount of energy for welding materials without overwhelming them with heat. No matter which type of laser welding machine you choose, it’s important to select one that meets your specific needs, whether you’re welding small medical devices or large-scale manufacturing components.

Fiber Laser Welding Machines

Fiber laser welding machines are widely used in industries due to their precision and efficiency. There are different types of these machines available, each with its own unique features. One type is the fiber optic laser welding machine, which uses a fiber optic cable to deliver the laser beam.

This type of machine offers high beam quality and excellent stability. Another type is the galvanometer laser welding machine, which uses a high-speed mirror to deflect the laser beam. This machine is ideal for welding small and intricate parts with high precision.

Another type is the robotic laser welding machine, which is operated by a robot arm. This machine is suited for welding large and heavy parts that require a lot of precision. Regardless of the type, fiber laser welding machines offer higher precision and efficiency compared to traditional welding methods.

They can also provide cost savings due to their faster welding speeds and lower material waste.

CO2 Laser Welding Machines

CO2 laser welding machines are highly efficient and versatile tools in the manufacturing industry. They are used in various applications such as welding, cutting, drilling, and engraving. These machines use a high-powered CO2 laser to generate a beam that is focused and directed towards the material being welded.

There are four main types of laser welding machines: continuous wave, pulsed, hybrid, and quasi-continuous wave. The continuous wave machine produces a constant beam that can weld continuously. Pulsed machines create intermittent bursts of energy that are ideal for welding thin materials.

Hybrid machines combine the characteristics of both continuous wave and pulsed machines. Lastly, the quasi-continuous wave machine provides a balance between the two, offering a higher power output than pulsed machines, but with more control over the heat input. Each type of machine is unique in its own way, and the choice typically depends on the specific application.

Ultimately, CO2 laser welding machines are a powerful and cost-effective solution for any business looking to improve its manufacturing processes.

YAG Laser Welding Machines

YAG laser welding machines. When it comes to laser welding machines, there are various types available, each with its unique features and benefits. One popular type is the YAG laser welding machine.

This machine is ideal for welding metals like steel, aluminum, and titanium. One of its unique features is that it uses a crystal as a lasing medium to produce a highly concentrated beam of light. The YAG laser welding machine is highly effective in producing high precision and high-quality welds.

It is also versatile and can be used for welding a variety of metals and alloys. This machine is perfect for applications that require clean and precise welds, as well as for mass production where high-speed welding is needed. Overall, the YAG laser welding machine is a reliable and efficient tool for the welding of metals and offers numerous benefits over traditional welding techniques.

Applications of Laser Welding Machines

A laser welding machine is a tool that uses a high-intensity laser beam to join two pieces of metal or other materials together. These machines are commonly used in manufacturing, particularly in the automotive, aerospace, and medical industries. They are highly precise and produce a high-quality weld, making them an ideal choice for joining intricate parts or pieces that require a high level of accuracy.

Additionally, laser welding machines are versatile and can be configured to weld a wide range of materials, from metals and plastics to ceramics and even glass. Their ability to make small, precise welds also makes them useful for repairing electronics and other delicate devices. Overall, laser welding machines are a valuable tool that offer a wide range of applications for modern manufacturing processes.

Automotive Industry

The automotive industry regularly uses laser welding machines for a variety of applications, including body construction and component joining. Laser welding technology is crucial in automotive manufacturing because it delivers a fast, strong, and precise weld with minimal heat impact. In body construction, laser welding machines create strong bond spots in various positions, ensuring that the car body withstands forces during impact.

In component joining, laser welding machines weld intricate and thin parts, such as connecting rods, sprockets, and cylinder sleeves. These parts require a precise, stable, and distortion-free weld, which is achievable with laser welding technology. Additionally, laser welding machines facilitate high-volume production, offering automotive manufacturers a cost-effective and efficient solution.

Laser welding technology also reduces the number of manual processes required, thereby minimizing the car’s assembly time. In summary, laser welding machines bring immense benefits to the automotive industry, including precision welding, minimal distortion, cost-effective welding solutions, and high-volume production. It is a critical technology that has revolutionized automotive manufacturing.

Aerospace Industry

Laser welding machines have revolutionized the aerospace industry with their ability to make precise and high-quality welds. One of the primary applications of laser welding machines in aerospace is the manufacturing of aircraft engine components. These machines can be used to join complex shapes and thin materials that would be difficult or impossible to weld using traditional welding techniques.

With laser welding, joints can be created with minimal heat and distortion, which is essential for maintaining the integrity of the component. Furthermore, laser welding machines allow for automated manufacturing, which increases productivity and reduces the risk of human error. The use of laser welding machines has resulted in stronger and more reliable aircraft engines, making air travel safer and more efficient.

As the aerospace industry continues to evolve, it is clear that laser welding machines will play an essential role in advancing technology.

Benefits of Laser Welding Machines

A laser welding machine is a modern piece of technology that uses a highly concentrated beam of light to fuse two or more materials together. With this process, high-quality welding with minimal distortions can be achieved, providing numerous benefits to industries such as automotive, aerospace, medical and electronics. The laser welding machine has a very high power output that can deliver deep penetration into materials while maintaining a high accuracy and speed.

This results in extremely strong welds that are highly resistant to cracking and have uniformity. Additionally, laser welding machines are highly versatile and can weld materials of different thicknesses and shapes, making them suitable for use in a wide range of applications. They are also more efficient than traditional methods, producing fewer emissions and allowing for easier control over the weld location.

Overall, the precision, efficiency, and strength of laser welding machines make them an essential tool for modern manufacturing industries.

Conclusion

In conclusion, a laser welding machine is like a superhero of bonding materials. Using its concentrated beam of light, it can join materials together with precision and speed, making it a popular tool for industries such as automotive and aerospace. Whether you’re looking to melt, vaporize, or just straight-up fuse materials, a laser welding machine is the go-to solution.

So next time you see a laser welding machine, remember – it’s not just a tool, it’s a high-tech joining force to be reckoned with!”

FAQs

What is a laser welding machine?

A laser welding machine is an industrial tool that uses a high-powered laser beam to form a precise and controlled weld between two materials.

What are the advantages of using a laser welding machine?

Laser welding machines offer high quality welds with minimal distortion, no physical contact between the tool and workpiece, and faster cycling time compared to traditional welding techniques.

What materials can be welded with a laser welding machine?

Laser welding machines can be used to weld a variety of materials, including metals, plastics, and ceramics.

How does a laser welding machine work?

A laser welding machine generates a high-powered laser beam that is focused onto the workpiece to melt and fuse the materials together.

What industries use laser welding machines?

Laser welding machines are used in a variety of industries, including automotive, aerospace, medical device manufacturing, and jewelry making.

How expensive are laser welding machines?

The cost of a laser welding machine depends on its capabilities and the materials being welded, but they typically range from tens of thousands to hundreds of thousands of dollars.

Can laser welding machines be automated?

Yes, laser welding machines can be automated using robotics and computer control to increase precision and efficiency in the welding process.