Have you ever tried starting an electric motor and instead of the sweet sound of a successful start you hear an annoying hum? It seems like your motor is telling you it wants to do something but…

just can’t. So what’s the deal? This blog post will dive into the reasons why an electric motor may hum but not fully start. We’ll discuss the common causes of this issue and provide some solutions for fixing it so that you can get your motor up and running again.

Introduction

Have you ever tried to switch on an electric motor but all you hear is a humming sound with no signs of it starting? It can be frustrating when your machine fails to cooperate despite all your efforts. There are several reasons why this could be happening. One likely cause is that the motor’s capacitor may be defective.

This component provides the necessary burst of energy to overcome the inertia and set the motor in motion. If it’s not working correctly, the motor may be unable to start. Another possibility could be that a fault has developed in the motor windings, which can cause them to short-circuit, leading to a humming noise.

Another common cause of a humming motor could be an electrical overload, causing the machine to trip the circuit breaker or blow a fuse. Whatever the reason may be, it’s always better to seek help from a qualified electrician to avoid further damage to the motor.

Explaining what an electric motor is and how it works

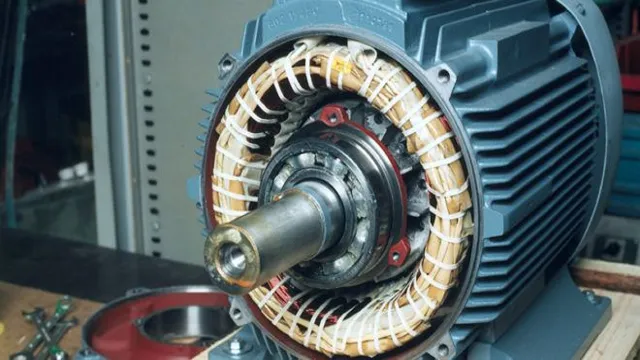

An electric motor is a device that converts electrical energy into mechanical energy to produce motion. It consists of two main parts, a stationary part, and a rotating part. The stationary part is called the stator, which contains a series of windings that generate an electromagnetic field when an electric current flows through them.

The rotating part is called the rotor, which is mounted on a shaft and contains a series of magnets that are attracted to the electromagnetic field generated by the stator. When an electric current is introduced to the stator windings, it creates a magnetic field that causes the rotor to rotate, producing mechanical energy. The speed and direction of the motor can be controlled by varying the amount and direction of the electric current supplied to the stator windings.

Electric motors are used in a wide range of applications, from powering industrial machinery to operating electric vehicles. Understanding how an electric motor works is crucial in modern technology and innovation.

Reasons Why an Electric Motor Will Hum and Not Start

When an electric motor hums but doesn’t start, it can be frustrating. However, understanding the reasons why this can happen will help in troubleshooting the issue. The most common cause is a faulty starting capacitor.

This small electrical component is responsible for initiating the motor’s spinning motion and if it fails, the motor will simply hum and not start. Another possible cause is a defective centrifugal switch. This switch is responsible for stopping the capacitor once the motor reaches a certain speed, but if it fails, the motor won’t start at all.

Other potential culprits include a stuck rotor, a jammed bearing, or a damaged motor winding. Troubleshooting and fixing these issues may require the expertise of an electrician or motor repair specialist, but with the right knowledge, it’s possible to diagnose and resolve the problem.

Troubleshooting the power source

When an electric motor hums and fails to start, it could be due to several reasons related to the power source. One common culprit is a faulty capacitor, which is an electronic component that stores energy and helps provide the initial boost of current to start the motor. If the capacitor is weak or damaged, it can cause the motor to hum or get stuck, even though it may appear to be functioning.

Another possible issue is a problem with the start or run windings of the motor, which are coils of wire that create the magnetic field needed for movement. If these windings are damaged or have poor connections, the motor may hum or produce a clicking sound instead of running. In some cases, the problem may be as simple as a tripped circuit breaker or a loose connection in the power supply.

By troubleshooting these common issues, you can determine the cause of the humming and take the necessary steps to fix the motor. Remember to always use safety precautions when handling electrical components to avoid injury or damage to the equipment.

Faulty Capacitor

If you notice your electric motor humming but not starting, there could be a variety of reasons why. One of the most common culprits is a faulty capacitor. The capacitor plays an important role in providing the motor with the initial jolt of energy it needs to start running.

If it’s not working properly, the motor won’t be able to get that initial boost and will simply hum instead. Another potential issue could be a faulty start switch or wiring issue, which can prevent the motor from receiving the necessary power. In some cases, the problem may even be linked to the power source itself, such as a blown fuse or tripped circuit breaker.

In any case, it’s essential to troubleshoot the problem and address it promptly to prevent further damage to the motor.

Defective Start Switch

If you’ve ever turned on an electric motor only for it to hum and not start, you might be wondering what’s causing the problem. One of the most common culprits is a defective start switch. This small component is responsible for sending power to the motor’s windings, which get it moving.

However, if the start switch is faulty or worn, it may not be able to engage properly, which can cause the motor to hum without starting. In some cases, the switch may need to be cleaned or replaced in order to restore proper function. If you’re experiencing this issue, it’s important to properly diagnose the problem before attempting any repairs, as working with electrical components can be dangerous.

Bring in a qualified technician to help you get your electric motor up and running again.

Worn Bearings

When you turn on your electric motor and it just hums instead of starting up, you might have worn bearings. These are a common cause of electric motor malfunction, and they can be caused by a range of factors. Over time, the lubricant in the bearings can break down, causing the metal surfaces to rub against each other.

This can lead to pitting, scoring, and eventually, wear. Worn bearings can cause the motor to hum, but they can also cause other issues like overheating, vibration, and reduced efficiency. If you suspect that your electric motor has worn bearings, it’s important to address the issue as soon as possible to avoid further damage.

A professional technician can assess the situation and provide guidance on how to repair or replace the bearings. By taking care of your electric motor and keeping an eye out for signs of wear and tear, you can keep it running smoothly and efficiently for years to come.

Preventive Maintenance Tips

If you ever notice that your electric motor is humming but not starting, there could be several reasons for this issue. It could be caused by a broken or loose connection, a faulty capacitor, or a faulty motor winding. Additionally, the motor may not be receiving sufficient power due to a malfunctioning electrical panel or circuit breaker.

When an electric motor doesn’t receive adequate power, it will attempt to turn, causing a humming sound. If left unchecked, it can lead to damage to the motor or cause it to burn out completely. Preventive maintenance is key to avoiding such scenarios.

To prevent the motor from humming and not starting, check all connections and wires periodically, replace any damaged or worn components, and verify that your electrical panel and circuit breakers are functioning properly. By following these simple steps, you can ensure your electric motor runs smoothly and efficiently.

Regular Lubrication

Regular lubrication is essential for maintaining the longevity of your equipment and machinery. It can help reduce friction and wear and tear on moving parts, which can ultimately lead to costly repairs and equipment downtime. But how do you ensure you’re performing regular lubrication correctly? First and foremost, it’s important to refer to your equipment’s owner manual for guidelines on the type and frequency of lubrication.

Typically, it is recommended to lubricate every 250 hours of operation or once a month. Secondly, ensure you’re selecting the appropriate lubricant for the specific application and avoid over-lubricating, which can cause excess buildup and hinder performance. Finally, make sure to clean and inspect the equipment before lubricating to ensure no debris or contaminants are present.

Remember, regular lubrication may seem like a small task, but it can have a big impact on the overall health and performance of your equipment, so don’t skimp on this essential maintenance step.

Checking Electrical Connections

Checking electrical connections is an essential part of preventive maintenance to ensure maximum safety and functionality of your electrical systems. It’s crucial to inspect your electrical connections regularly and fix them immediately if there are any signs of wear or damage. Loose connections can cause intermittent power issues or even lead to electrical fires.

You can check your connections by turning off the power supply, removing the cover plates, and checking for loose wires or corrosion. Additionally, you can invest in high-quality connectors and terminals that offer long-lasting performance. So, don’t take any chances when it comes to your electrical connections and ensure that you keep them in good condition for a safer and more reliable electrical system.

Conclusion

In essence, an electric motor humming but failing to start can be likened to a musician tuning their instrument but forgetting to play the song. Whether it’s due to a faulty capacitor, low voltage, or insufficient torque, something is preventing the motor from transforming electrical energy into mechanical power. In such cases, it’s important to troubleshoot and identify the root cause of the issue before it takes a toll on the motor’s health.

Remember, just like a musician needs the right conditions to perform, an electric motor requires the right conditions to start humming and doing what it does best – powering machinery and devices with ease.”

FAQs

Why is my electric motor humming but not starting?

The most common cause for this issue is a faulty capacitor, which can prevent the motor from receiving enough power to start up.

Can a clogged air filter cause an electric motor to hum and not start?

Yes, if the air filter becomes clogged with dirt and debris, it can restrict the flow of air to the motor and cause it to struggle to start up, resulting in a humming sound.

What is the role of the centrifugal switch in an electric motor and could its failure cause humming and starting issues?

The centrifugal switch helps to engage the starting winding in the motor and disengage it once the motor reaches a certain speed. If it fails, the motor may not start up properly and emit a humming sound.

How can I tell if the bearings in my electric motor are causing it to hum and not start?

You can listen for a grinding or clicking sound when you try to start the motor, which can indicate that the bearings are damaged and preventing the motor from operating smoothly.

Can low voltage or inadequate wiring cause electric motor humming and starting issues?

Yes, if the motor is not receiving enough power due to low voltage or improper wiring, it may struggle to start up and hum instead.

What is the importance of regular maintenance for electric motors and how can it prevent humming and starting issues?

Regular maintenance, such as cleaning, lubricating, and checking electrical connections, can help prevent issues that can cause humming and starting problems in the motor.

How can I troubleshoot electric motor humming and starting issues on my own?

You can check for loose or damaged wiring, test the capacitor, and inspect the bearings and other components to determine the cause of the issue and take appropriate action. If you are unsure, it is best to consult a professional.