Have you ever wondered how to check the compression of your snowmobile’s engine? It’s an essential part of maintenance that can prevent costly repairs and keep your ride in peak condition. A compression tester is a tool used to measure the pressure inside the engine cylinders, which can indicate if there are any underlying issues with the engine’s internal components. Like a stethoscope for your snowmobile, a compression tester can reveal what’s going on beneath the surface and help you diagnose and prevent problems before they become more serious.

In this blog, we’ll explore how to use a compression tester on a snowmobile and why it’s an essential part of snowmobile maintenance. Let’s dive in and get started!

Gather Tools and Materials:

If you want to know how to use a compression tester on a snowmobile, the first thing you need to do is gather the tools and materials required for the job. You will need a compression tester, typically available at any automotive parts store, as well as a set of open-end wrenches. You will also need to drain the oil from the snowmobile’s engine before proceeding with the compression test.

Make sure you have a container ready to collect the drained oil. Once you have everything ready, you can begin the compression test. It’s important to follow the instructions for using the tester carefully, as the procedure may vary depending on the model of the snowmobile.

A compression test can be a useful tool in diagnosing engine problems, so don’t hesitate to use it if you’re experiencing performance issues with your snowmobile.

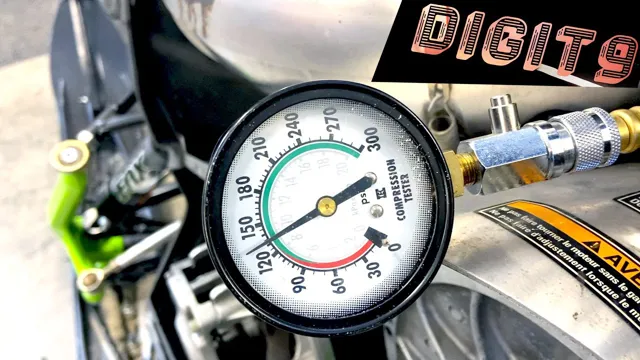

Compression tester

If you want to keep your car running smoothly, a compression tester is an essential tool for diagnosing engine problems. Before you start, make sure you have everything you need: a compression tester kit, a ratchet wrench, a spark plug wrench, and a set of replacement spark plugs. It’s best to work on a cold engine, so wait a few hours after running your car before beginning.

Start by removing one of the spark plugs with the spark plug wrench and attaching the compression tester to the hole. Ask a friend to turn the key and crank the engine a few times while you read the gauge on the compression tester. Repeat this for each cylinder in your car’s engine.

By comparing results, you’ll be able to diagnose any problems with your engine – such as low compression due to damaged valves or piston rings. With the right tools and a little know-how, you can keep your car in top shape.

Screwdriver

When it comes to fixing things around the house, having the right tools is essential. One tool that is an absolute must-have for any toolbox is a screwdriver. To gather the tools and materials needed for a screwdriver, first, you will need to purchase one or locate one in your existing collection.

There are various types of screwdrivers available, each with a different head size and shape. Make sure to choose the appropriate type of screwdriver for the job you need to perform. You will also need to have screws or bolts that need to be tightened or loosened and a flat surface to work on.

Keep in mind that a screwdriver is not just a tool for repairs, but can also be used for opening paint cans, prying open lids, and more! So, always make sure to have one handy in your toolbox. With a screwdriver in your arsenal, taking on any repair task becomes a breeze.

Wrench

When it comes to fixing things, having the right tools is essential. And one of the most important tools you can have in your arsenal is a wrench. Before you start any project that requires the use of a wrench, you’ll want to make sure you have the right tools and materials on hand.

The first thing you’ll need, of course, is a wrench. There are many different types of wrenches out there, so be sure to choose the one that’s best suited to the job you’re doing. You’ll also want to have some kind of lubricating oil on hand, as this can help make the job easier and prevent damage to the wrench and the object you’re working on.

Other useful tools to have include pliers, a socket set, and a torque wrench. With these tools and materials by your side, you’ll be well-equipped to handle just about any job that comes your way.

Steps to Follow:

If you’re wondering how to use a compression tester on a snowmobile, you’ve come to the right place. Firstly, remove the spark plug and screw in the compression tester. Next, give a few pulls on the cord to gather readings.

Repeat this process for each cylinder. Generally, two-stroke snowmobiles require a compression test reading between 120 to 130 psi, while four-stroke should fall between 140 to 150 psi. If your snowmobile’s compression is significantly lower than the recommended range, there could be underlying engine issues that need to be addressed.

Conducting this test regularly helps ensure that your snowmobile’s engine is performing optimally so you can avoid breakdowns in the middle of snowy terrain. Keep in mind that compression testing should be carried out when your snowmobile is cold, otherwise, you may get an inaccurate reading due to the expansion of the heated air.

Remove the spark plugs from the cylinders

When it comes to maintaining your vehicle, there are a few tasks that can seem intimidating, but are actually easily doable with the right instructions. One of these is removing the spark plugs from the cylinders. By doing so, you can check the condition of your plugs and replace them if necessary.

To get started, make sure your engine is cool and the ignition is turned off. Locate the spark plug wires and carefully remove them by pulling them away from the plug. Use a spark plug socket and ratchet to loosen the plug by turning it counterclockwise.

Once you have removed the plug, inspect it for any signs of wear such as cracking or discoloration. If you notice any damage or if the electrode is worn down, it’s time to replace the plug. You can find the appropriate replacement plugs in your vehicle’s owner’s manual or by consulting with a professional mechanic.

Once you have your new plug, insert it into the cylinder and tighten it by turning it clockwise. Repeat this process for each of the cylinders, being sure to keep track of which plug goes where. Finally, reattach the spark plug wires to their corresponding plugs, making sure they are securely connected.

Removing and replacing your spark plugs may seem like a daunting task, but with a little bit of knowledge and some elbow grease, you can keep your vehicle running smoothly and efficiently. Remember to always follow proper safety procedures and consult with a professional mechanic if you have any concerns.

Connect the compression tester to the first cylinder

If you want to check the engine’s compression, the first step is to connect the compression tester to the first cylinder. This procedure is simple, but it requires some preparation. First, switch off the engine and let it cool for a while.

Then locate the spark plug and remove it using a socket wrench. Attach the compression tester’s hose to the cylinder’s spark plug hole and secure it with a threaded fitting. Ensure that the gauge’s valve is closed and start cranking the engine with the starter or by hand.

The gauge’s needle will move, indicating the cylinder’s compression. Check the value against the manufacturer’s specifications for your engine model. Repeat this procedure for each cylinder, and don’t forget to reconnect all the spark plugs after you’ve finished.

This simple step is crucial to obtaining accurate results and ensuring your engine’s optimal performance, so make sure you follow the manufacturer’s instructions correctly.

Crank the engine

When it comes to getting your engine started, you need to know the proper steps to follow to avoid any mishaps. The first step is to turn on the ignition switch, which will activate the electrical system. From there, you’ll need to step on the clutch pedal (if you have a manual transmission) and press the brake pedal.

Next, you’ll need to shift your car into neutral and turn the key to start the engine. Don’t hold the key for too long if the engine doesn’t start the first time. Repeat the process a couple more times until the engine cranks.

Once it does, you can release the clutch pedal and take your foot off the brake. Remember to always be aware of your surroundings and check that your car is in good condition before you hit the road.

Read the compression level on the gauge

When checking the compression level of your engine, the gauge is the best tool to use. The gauge will provide you with an accurate reading of how well your engine is functioning, and if there are any possible issues to address. To begin, place the gauge into the spark plug hole and turn the engine over a few times.

Then, read the compression level on the gauge. A reading between 100-140 psi is normal, but it’s important to consult your engine’s manual for the specific range for your engine. If the reading is too low, it could indicate a problem with the piston rings, valves, or head gasket.

On the other hand, a reading that’s too high could also point to issues with the engine’s overall performance. Therefore, you should always pay attention to the gauge’s reading and take necessary actions to maintain the compression level for better engine performance and longevity.

Repeat the process on all cylinders

When you’re working on your vehicle’s engine, it’s imperative to follow the steps correctly, especially when it comes to servicing the cylinders. After finishing the first step of loosening the spark plug, you should remove it carefully and double-check to ensure that it is not damaged. Then, you can take the compression gauge and thread it into the spark plug hole, making sure that it is tightly sealed.

Next, you need to turn the engine over by either starting it or using a hand crank to get a compression reading. Repeat this process on all cylinders of your vehicle to ensure all of them are functioning correctly. It’s essential to be patient and take your time with each step to avoid any potential mishaps during the servicing process.

By following these steps, you can keep your vehicle’s cylinders in good condition and avoid any potential issues down the road.

Interpreting Results:

If you’ve used a compression tester on your snowmobile, the next step is to interpret the results. The compression reading is an important diagnostic tool that helps you determine the engine’s overall condition and identify potential issues. A healthy engine should have a compression reading that falls within the manufacturer’s recommended range, typically between 90-150 psi.

If the reading is lower than the recommended range, this indicates a compression loss and potential problems such as worn piston rings or a leaking head gasket. On the other hand, unusually high compression readings can point to issues like carbon buildup or a stuck valve. Remember that a compression test alone doesn’t tell the whole story, and you should combine it with other diagnostic tests to get a complete picture of your engine’s health.

In summary, using a compression tester on a snowmobile is a valuable step towards diagnosing engine problems, but understanding and interpreting the results is equally important in maintaining your machine’s performance.

Compare readings between cylinders

When comparing readings between cylinders in an engine, it’s essential to understand what the numbers mean and how they can help you diagnose problems. Generally, each cylinder should have similar readings in terms of compression, vacuum, and fuel pressure. If there’s a significant difference between the readings of two or more cylinders, it could indicate an issue with the engine’s internal components.

For example, low compression in a cylinder could indicate worn or damaged piston rings, while high vacuum could signal a bad intake or exhaust valve. On the other hand, if the readings are consistently low across all cylinders, it could mean there’s a problem with the fuel system, such as a clogged fuel filter or a faulty fuel pump. Whatever the issue may be, comparing readings between cylinders can provide vital clues to help you troubleshoot and resolve engine problems.

So, if you notice a discrepancy, it’s best to investigate further to prevent additional damage and costly repairs.

Check readout against your snowmobile’s manufacturer specifications

After obtaining the readout from your snowmobile’s diagnostics tool, it’s essential to interpret the results accurately. Firstly, ensure that the values obtained meet your snowmobile manufacturer’s specifications. This step guarantees the accuracy of your readout and that no underlying issues affect your snowmobile’s performance.

There are numerous figures to examine when interpreting your results, such as engine temperature, battery voltage, and fuel economy. Understanding these values and the relationship between them can help identify any inefficiencies in your snowmobile’s system, aiding in better maintenance and performance. Additionally, some diagnostic tools provide troubleshooting recommendations and code interpretations to help you narrow down a problem’s source.

Therefore, it’s critical to comprehend your diagnostics readout to maintain your snowmobile’s optimal functioning for a long period, reducing pricey repairs and making your journey more enjoyable.

Conclusion:

In conclusion, using a compression tester on a snowmobile isn’t rocket science, but it can be the difference between a smooth ride and a disaster on the slopes. The key is to make sure the engine is warm, the spark plugs are removed, and the throttle is wide open. From there, simply attach the tester, crank the engine a few times, and voila – you’ll be able to measure the pressure and diagnose any issues that may be lurking under the hood.

So if you want to keep your snowmobile running like a dream this winter, remember to grab a compression tester and give your engine the TLC it deserves!”

Using a compression tester is a simple process that can help diagnose issues with a snowmobile’s engine.

After using a compression tester to diagnose issues with your snowmobile’s engine, it’s important to properly interpret the results. Generally, a healthy engine should have a compression reading of around 100 psi, though this can vary depending on the make and model of your snowmobile. A compression reading below 90 psi could indicate a problem with the piston rings, cylinder walls, or valves, while a reading above 110 psi could suggest problems with carbon buildup or a damaged gasket.

It’s best to consult your snowmobile’s manual or a professional mechanic to determine the specific cause of any compression issues. Overall, using a compression tester is a simple yet effective way to diagnose problems with your snowmobile’s engine and ensure it’s running at its best.

FAQs

What is a compression tester and how does it work on a snowmobile?

A compression tester is a tool used to measure the compression in each cylinder of a snowmobile’s engine. It works by screwing into the spark plug hole and then using a gauge to measure the pressure.

Why is it important to use a compression tester on a snowmobile?

Snowmobile engines rely heavily on compression to generate power, so it’s important to regularly test the compression to make sure the engine is running at its best. Low compression can lead to poor performance and eventually engine damage.

How do I prepare my snowmobile for a compression test?

Before using a compression tester, make sure the snowmobile is warmed up and the battery is fully charged. Remove the spark plugs and throttle set screws, and then screw in the compression tester.

What is a good compression reading for a snowmobile?

A good compression reading for a snowmobile engine is typically between 100-150 PSI.

What should I do if I get a low compression reading on my snowmobile?

If you get a low compression reading, it may be necessary to do further diagnostic testing to determine the cause. Common causes of low compression include worn piston rings, damaged valves, and cylinder wear.

Can I use a compression tester on any snowmobile engine?

Compression testers can be used on most snowmobile engines, but make sure to consult the owner’s manual for specific instructions and any engine-specific requirements.

How often should I use a compression tester on my snowmobile?

It’s recommended to test the compression on your snowmobile’s engine at least once a year, or more frequently if you notice any performance issues. Regular compression testing can help catch potential issues early and avoid costly repairs down the road.