So, you’ve recently bought a new scope and you’re excited to mount it on your rifle. But, you don’t have a torque wrench to ensure that your scope rings are tightened to the appropriate amount. Don’t worry, we’ve got you covered.

Tightening your scope rings without a torque wrench may seem daunting, but it’s actually a fairly simple process. Firstly, ensure that you have the correct sized hex key or screwdriver for your scope rings. Using the wrong sized tool can damage the screws or cause the rings to become misaligned.

Secondly, tighten the screws a little bit at a time in a criss-cross pattern. This helps to distribute pressure evenly and prevent warping or bending the scope or rings. It’s important to note that you don’t need to tighten the screws too much.

Over-tightening can damage the scope, affect accuracy, and cause the screws to strip. Use your best judgement when tightening and listen to the sound of the screws. They should be snug, but not excessively tight.

While a torque wrench can provide more precision and reassurance, it’s not always necessary for mounting a scope. With a little bit of knowledge and care, you can achieve a secure and stable mount for your scope without the use of a torque wrench. Happy shooting!

Gather Necessary Materials

Tightening scope rings can be a tricky process, especially if you don’t have a torque wrench on hand. However, fear not! With a few essential materials, you should be able to do it easily. First, you’ll need a screwdriver that fits the screws on your scope rings.

Additionally, a thread locker is crucial to ensure the screws don’t come loose over time. Finally, you’ll want a level to make sure your scope is mounted correctly. While not necessary, a padded vice can also be helpful for securing your gun while you work.

With these materials, you’ll be able to tighten your scope rings without a torque wrench in no time.

Materials list: screwdriver, pliers, gun oil, thread locking compound (optional)

Before beginning any gun cleaning or maintenance task, it is crucial to gather all necessary materials. The most basic tools required are a screwdriver and pliers to disassemble and reassemble the firearm. Additionally, gun oil is essential for lubrication and protecting metal surfaces.

Thread locking compound is an optional material that can be used to ensure screws and bolts stay in place during use. Failure to have the right tools on hand can compromise the safety and effectiveness of firearm maintenance efforts. Therefore, it is always recommended to check materials lists beforehand and make sure everything is readily available.

Think of it as preparing for battle, but instead of a sword and shield, it’s a screwdriver and gun oil. So, gather your materials and get ready to keep your firearm in top-notch condition!

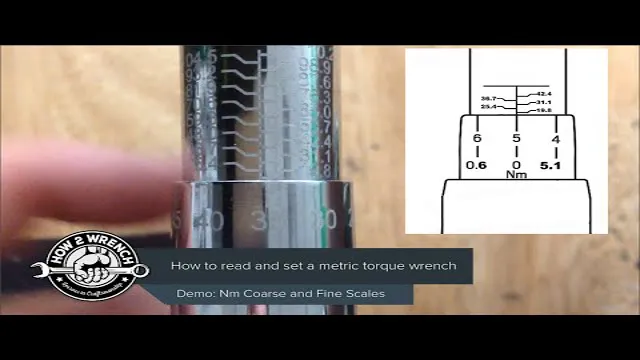

Understand Proper Torque Values

If you want to know how to tighten scope rings without a torque wrench, the first thing to understand is the importance of proper torque values. Torque is the force used to tighten screws or bolts, and it’s vital to achieving the right amount of pressure required to hold your scope securely in place. Without a torque wrench, it can be challenging to get the tension just right, but there are a few tricks you can use.

One method is to use a small amount of thread locking compound on the screws to ensure they stay in place. Another is to hand-tighten the screws, then use a screwdriver to tighten them just a bit more. Remember to use a crisscross pattern when tightening the screws to distribute the pressure evenly.

It may take some practice to get the hang of it, but with a little patience and attention to detail, you can tighten scope rings without a torque wrench and ensure your scope stays put.

Refer to manufacturer’s instructions or contact customer service

When it comes to tightening bolts, understanding the proper torque values is essential. Every manufacturer has specific specifications to follow when it comes to tightening bolts, and it’s crucial to follow these instructions to avoid damaging the components. Some people tend to overtighten bolts, which can lead to broken parts or stripped threads, creating more problems than before.

On the other hand, undertightening can cause critical components to come loose, leading to significant failures and safety hazards. To prevent such issues, always refer to the manufacturer’s instructions or contact their customer service for guidance on the proper torque values for their products. A simple phone call or email can save you from expensive repairs or potential safety risks later on.

So next time you’re tightening a bolt, remember always to follow the directions and use the recommended torque values.

Hand-Tighten Screws

If you’re looking to mount a scope onto your rifle, you may be wondering how to tighten scope rings without a torque wrench. One option is to hand-tighten the screws. This may sound like a simple solution, but it can actually be quite effective.

The key is to make sure you don’t overtighten the screws, which can cause damage to your scope or rifle. To hand-tighten the screws, you’ll need to first place the scope rings onto the rifle. Then, starting with the top screw, use a screwdriver or Allen wrench to tighten the screw until it feels snug.

Repeat this process with the bottom screw and then move on to the second set of screws. Again, tighten the top screw first, followed by the bottom, until they feel snug. Keep in mind that you don’t want to use too much force or tighten the screws too much.

Instead, use a gentle hand to tighten the screws just enough to hold the scope in place. With a little practice, you’ll be able to master the art of hand-tightening scope rings and mounting your scope like a pro.

Use screwdriver to hand-tighten screws until they are snug

When it comes to assembling furniture or fixing something around the house, it’s important to tighten screws properly. One of the first steps in this process is to hand-tighten screws until they feel snug. This means you should use a screwdriver and apply just enough pressure to ensure the screw is secure but not overtightened.

Over-tightening screws can cause damage to the material and even strip the threads, making it difficult to use in the future. Think of it like shaking someone’s hand – you want to grip firmly, but not so tight that it becomes uncomfortable. This process is crucial because it sets the foundation for the rest of the project and ensures that everything is secure.

By hand-tightening screws, you’re taking the first step towards a successful DIY project.

Check Alignment

If you want to tighten your scope rings without a torque wrench, there are a few steps to follow. The first step is to check the alignment of the rings. Make sure they are level with each other and that they are not crooked or tilted in any way.

You can do this by looking at the rifle from different angles and making sure the scope is not leaning in any particular direction. Once you have determined that the rings are aligned, you can begin tightening them. Start by turning each screw a little bit at a time until they are snug.

Don’t overtighten, as this can damage the scope or the rings. Finally, check the alignment again to make sure it hasn’t shifted during the tightening process. By following these steps, you can tighten your scope rings without a torque wrench and ensure that your scope is properly secured to your rifle.

Look down the scope to ensure proper alignment before final tightening

When mounting a scope on your rifle, proper alignment is crucial for optimal accuracy. Before finalizing the tightening process, it’s important to check the alignment through the scope. Otherwise, you may experience bullet drift and inaccurate shots.

To check the alignment, first, securely mount the scope on the rifle and then look through the scope at a distant object. Next, rotate the rifle to ensure the crosshairs stay on the object and don’t go off-center. If the crosshairs move away from the target, adjust the scope until the crosshairs align with the object.

This may involve adjusting the windage and elevation knobs on the scope. Once you’re satisfied with the alignment, you can begin the final tightening of the scope rings. By taking the time to check alignment before final tightening, you’ll ensure that your rifle is as accurate as possible, allowing you to hit targets with greater precision.

Use Pliers for Additional Tightening

If you find yourself needing to tighten scope rings without a torque wrench, don’t worry – there’s a solution. One method is to use pliers for additional tightening. Start by securing your rifle in a vice, being careful not to damage any of its components.

Next, use an appropriately sized pair of pliers to grip the exposed portion of the scope ring and twist it until it feels secure. Keep in mind that you want to tighten the scope rings just enough to prevent the scope from moving, but not so much that you risk damaging it. Once you’re satisfied with the fit and security of the scope, you’re ready to take aim and fire away! While it might not be as precise as using a torque wrench, using pliers can be a simple and effective solution for tightening scope rings when you need it most.

Use pliers to tighten screws a little at a time

When it comes to tightening screws, many people rely on their trusty screwdriver. However, sometimes even the tightest grip with a screwdriver isn’t enough to get the job done. That’s where pliers come in handy.

By using pliers to provide additional torque, you can tighten screws more securely. But don’t just grab the pliers and crank away; it’s important to tighten the screw a little bit at a time to prevent stripping or damaging the screw or the surrounding material. Simply grip the screw with the pliers and turn it a little bit, then release and adjust your grip to do it again.

Repeat until the screw is tight and secure. Whether you’re working on a project at home or performing maintenance on a vehicle, using pliers for additional tightening can make all the difference. So, next time your screwdriver just isn’t cutting it, try using pliers instead for that extra bit of torque.

Test Fire and Recheck Tightness

If you’re wondering how to tighten scope rings without a torque wrench, don’t worry, it’s possible! The key is to test fire and recheck the tightness until you achieve the desired level of stability. First, ensure that the bases are securely attached to the rifle. Next, apply a small amount of thread locker to the screw threads before securing the scope rings to the bases.

Use a screwdriver to tighten the screws until they are snug, but be careful not to overtighten as this can cause damage to your rifle or scope. Finally, test fire the rifle to check the stability of the scope. If there is any movement or looseness, recheck the screws and adjust until your scope rings are tight and secure.

By following these steps, you can tighten your scope rings without the need for a torque wrench and ensure that your rifle is accurate and stable for your next shooting session.

Ensure screws remain tight after firing a few shots

When it comes to using power tools, safety is always a top priority. That’s why it’s important to regularly check the tightness of screws on your tools. After firing a few shots, it’s easy for screws to become loose due to the tool’s vibrations.

This can be dangerous, making it essential to always test fire and re-check tightness. While it may seem like an inconvenience, it only takes a few seconds to do and can prevent the risk of injury or damage. Think of it like tightening the bolts on a car wheel – if they’re loose, you wouldn’t drive around without fixing them first.

So, whether you’re using a power drill or an impact driver, always remember to test fire a few shots and check the tightness of your screws for added safety and peace of mind.

Conclusion

When it comes to tightening your scope rings, you don’t always need a torque wrench to get the job done. Instead, you can use some tried-and-true techniques that will ensure a tight fit for your scope. Whether it’s using thread locking compound, alternating tightening patterns, or using a simple hand tool, there are many ways to get the job done.

So next time you need to tighten your scope rings, remember that a little ingenuity can go a long way! Just be sure to take your time and don’t overdo it – after all, you want your equipment to stay snug and secure, not damaged and loose. Happy shooting!

Tightening scope rings without a torque wrench is possible with proper technique

Scope Rings Tightening scope rings without a torque wrench is possible with the proper technique. When mounting a riflescope, it’s essential to ensure that the scope rings are tightened correctly, as loose rings can cause harm to the firearm or even lead to accuracy issues. A torque wrench might not be available to everyone, but it’s still possible to determine the required tightness for the ring screws manually.

The trick is to start by tightening the screws slightly, followed by checking for the level of tightness and then further tightening them until they’re snug. It’s important not to over-tighten the screws as it can cause unnecessary stress on the firearm’s finish. After the ring screws are at the right tightness, testing the firearm through a few shots will ensure that everything is in order and to recheck the screws’ tightness afterward.

Using the manual tightening technique is particularly useful in remote areas without access to torque wrenches and is a great alternative for gun enthusiasts who are passionate about firearm maintenance.

FAQs

Can I tighten scope rings without a torque wrench?

Yes, you can use a regular screwdriver or Allen wrench to tighten the screws until they are snug but not over-tightened.

What if I over-tighten my scope rings?

Over-tightening your scope rings can damage your scope or cause it to not function properly. It is best to use a torque wrench if possible to prevent damage.

How do I know when my scope rings are tight enough?

Use a torque wrench to tighten the screws to the recommended torque settings. If you don’t have one, tighten the screws until they are snug but not over-tightened.

What if one of my scope ring screws is stripped?

If one of your scope ring screws is stripped, it’s best to replace the screw with a new one to ensure a secure and safe fit.

Can I use threadlocker on my scope ring screws?

Yes, using threadlocker on your scope ring screws can help prevent them from coming loose over time. But make sure to use a threadlocker that is safe for use on firearms.

What should I do if my scope rings keep coming loose?

Check to make sure that your scope rings are properly aligned and that the screws are tightened to the recommended torque settings. If they continue to come loose, you may need to replace the screws or the rings themselves.

Can I reuse scope ring screws if I take them out?

It depends. If the screws are in good condition and not stripped, you can reuse them. However, it’s always best to err on the side of caution and replace them with new ones if in doubt.