Are you tired of dealing with warped lumber? Straightening a warped 2×6 may seem like a daunting task, but with the right tools and a little bit of patience, you can get it looking good as new in no time. Whether it’s for a DIY project or a larger construction job, having straight lumber is essential for achieving a professional finish. In this article, we’ll walk you through step-by-step on how to straighten warped 2x6s, leaving you with straight, sturdy wood that’s ready for whatever project you have in mind.

So let’s dive in and get started!

Assessing the Warping

If you are working on a DIY project and have found that your 2×6 boards are warped, fixing the issue is crucial if you want to achieve a satisfactory final result. The first step is to assess the warping, which involves laying the board flat on the ground and inspecting for any bends or curves. If the warping is relatively minor, you may be able to correct it by using clamps to hold the board in place while applying heat from a heat gun.

However, if the warping is more severe, you may need to use a jointer or planer to remove the uneven areas before attempting to straighten the board. Regardless of the method you choose, it’s crucial to take your time and ensure that you don’t damage the board or compromise its structural integrity in the process. With patience and careful attention to detail, you should be able to straighten your warped 2×6 boards and achieve the desired final result.

Measuring the Warping

Assessing the warping of materials is an important step in ensuring their quality and durability. There are various ways to measure the warping, including visual inspection and advanced technologies such as laser scanning. Visual inspection involves looking for signs of bending, twisting, or other forms of deformation on the surface of the material.

Meanwhile, laser scanning provides a more accurate and detailed measurement, capturing the precise dimensions and shape of the material. This helps to identify any inconsistencies or irregularities in the material and can aid in predicting potential issues that may arise in the future. Properly assessing the warping of materials is crucial in a variety of industries, including construction, manufacturing, and engineering.

It allows for the identification and prevention of potential defects, ultimately increasing the overall quality and longevity of the material.

Determining the Cause of Warping

When it comes to assessing warping, the first step is to determine the cause of the issue. Warping can be caused by a range of factors, including uneven cooling, excessive heating, poor material quality, and incorrect printing settings. By carefully examining the printed object, you can identify the specific areas that are affected and assess the severity of the warp.

Additionally, it’s important to consider the size and shape of the object, as certain geometries may be more prone to warping than others. Once you’ve assessed the warping, you can begin taking steps to address the underlying cause and prevent it from occurring in future prints. By carefully monitoring your printer settings and taking steps to address any issues as they arise, you can ensure high-quality, warp-free prints every time.

Straightening Techniques

If you have a warped 2×6 board, there are several techniques you can use to straighten it. One simple method is to use moisture to your advantage. First, soak the board in water for several hours to allow the wood fibers to swell.

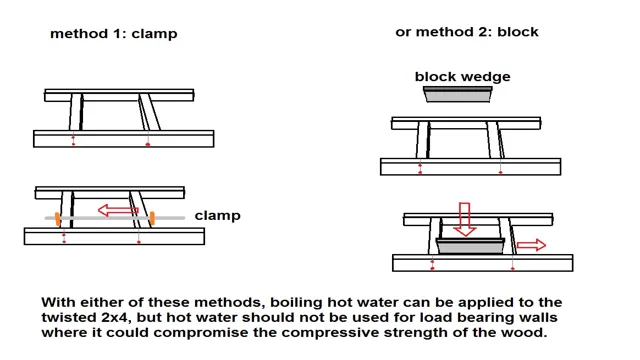

Then, place the board on a flat surface and clamp it down tightly, applying equal pressure to all sides. Leave it to dry completely before releasing the clamps and checking for straightness. Another option is to use heat to soften the wood fibers and straighten the board.

You can do this by placing the warped section of the board directly over a heat source, such as a stove burner or torch, until the fibers become pliable. Use clamps to straighten the board and hold it in place until it cools and the fibers retain their shape. These methods can be effective in fixing a warped 2×6, but it is important to note that they may not work in all cases.

It is always best to inspect the board carefully and determine the cause of the warp before attempting to fix it.

Using a Jointer

When it comes to woodworking, a jointer is an essential tool for straightening and smoothing out rough and uneven lumber. But how exactly does it work? One technique for using a jointer to achieve perfectly straight edges is called the “jointer jiggle.” This involves applying slight pressure to the board as it passes over the cutter head, causing it to flex just enough to even out any high or low spots.

Another technique is to use a straight edge to guide the board as it passes over the cutter head, ensuring a perfectly straight cut. Whether you’re a seasoned woodworker or just starting out, mastering these straightening techniques with a jointer can take your projects to the next level.

Using an Iron

As simple as it may seem, using an iron to straighten hair can be a little daunting. Even for the experts, knowing the right techniques can make the whole process smoother. Firstly, use a heat protectant spray on your hair before ironing to prevent any damage.

Divide your hair into manageable sections and use hair clips to keep them separated. Take small portions of hair at a time and glide the iron from the roots to the tips, keeping it in a slow and steady motion. Avoid pressing down too hard as it may cause damage or create unwanted bends.

The most important thing is to maintain a consistent temperature throughout the process to avoid overheating it. And voila, you’re left with beautifully straight hair that looks salon-fresh! Remember, the key to achieving perfect straight hair with an iron is to be patient and take your time.

Using Moisture

Moisture has long been known to play a crucial role in achieving sleek and straight hair. There are several techniques you can use to take advantage of this natural element to achieve that coveted straightened look. One popular approach is using the “wet-to-dry” method, which involves applying a heat protectant to damp hair before blow-drying with a natural-bristle brush.

This technique can help preserve moisture as you straighten your locks, ensuring they stay healthy and shiny. Another approach is using a steam straightener, which helps lock in moisture while flattening unruly strands. When using this technique, it’s important to ensure your hair is completely dry and to apply a heat protectant beforehand.

By harnessing the power of moisture, you can achieve a sleek, straight style while keeping your hair healthy and hydrated.

Tips for Preventing Warping

If you’re dealing with a warped 2×6, it can be frustrating to figure out how to straighten it out. Fortunately, there are a few tips and tricks you can use to prevent warping in the first place. Firstly, make sure to store your lumber in a dry, well-ventilated area.

Wood can absorb moisture from the air, which can lead to warping over time. Additionally, consider using a sealant or finish on your wood to help protect it from moisture and other environmental factors. Another option is to apply a weight to the wood while it’s drying to help keep it flat.

Finally, choose the right wood for your project, as some species are more prone to warping than others. By taking these steps, you can help ensure that your 2×6 stays straight and sturdy.

Proper Storage Techniques

Warping can be a frustrating problem to deal with when it comes to storage, as it can damage your items and make them unusable. However, there are some tips you can follow to prevent warping and keep your items in good condition. First, it’s important to make sure your storage area is properly ventilated to prevent moisture buildup, which can lead to warping.

You can also store your items flat or on their ends rather than standing them on their sides, which can cause uneven pressure and distortion. Additionally, using the right type of storage containers like plastic bins can help prevent warping in certain items by providing a sturdy and uniform environment. By taking these simple precautions, you can keep your items in great shape for years to come.

Choosing the Right Moisture Content

When working with wood, choosing the right moisture content is crucial to preventing warping. Wood is a natural material that can absorb and release moisture, causing it to expand and contract. If the moisture content is too high, the wood can warp or twist as it dries, leading to structural issues.

Ideally, the moisture content should be between 6% and 8%. To achieve this, you may need to dry out the wood slowly before use or use a moisture meter to check the levels. It’s also essential to store wood in a dry, well-ventilated area to prevent it from absorbing excess moisture.

By taking these steps, you can ensure that your wood stays in good condition for years to come, without any unsightly warping or twisting.

Conclusion

In conclusion, straightening a warped 2×6 requires a little bit of muscle and a lot of patience. But fear not, with the right tools and techniques, the process can be smooth sailing. Just remember to never force the board, take your time, and employ some creative thinking to get the job done.

And who knows, maybe you’ll even come out of it with a newfound appreciation for the art of woodworking. So go ahead, tackle that warped 2×6, and become the master carpenter you were always meant to be!”

FAQs

1. How does wood become warped? A: Wood can become warped due to changes in temperature, humidity, and moisture content. When exposed to high levels of moisture, boards can expand, causing them to warp or twist. 2. Can a warped 2×6 be straightened? A: Yes, a warped 2×6 can be straightened using various techniques such as clamping, steaming, or using weights to hold it in place while it dries. 3. Is it possible to prevent 2×6 boards from warping? A: While it is not always preventable, there are steps you can take to minimize the likelihood of your 2×6 boards warping. This includes storing them properly, applying a finish, and choosing the right type of lumber. 4. Can a warped 2×6 still be used for construction purposes? A: It depends on the severity of the warp and what the board will be used for. Minor warping may be acceptable for certain projects, but if the warp is too severe, it can compromise the strength and stability of the board, making it unsuitable for construction. 5. What are some common causes of warping in treated lumber? A: Treated lumber is more prone to warping due to the chemicals used in the treatment process, which can cause the wood to dry out unevenly. Additionally, if the boards were not properly dried before treatment, they may warp as they dry out over time. 6. How often should you check for warping in your lumber? A: It is a good idea to check your lumber periodically for warping, especially if it is being stored in an area with fluctuating temperature or humidity levels. Checking once every few weeks or months should be sufficient. 7. Do different types of wood warp differently? A: Yes, different types of wood have varying levels of susceptibility to warping. For example, softer woods like pine are more prone to warping than harder woods like oak or maple. Additionally, the way the wood is cut and dried can also affect its tendency to warp.