How to Shape Eva Foam Without a Heat Gun: Techniques and Tips

Are you looking for an alternative to using a heat gun when shaping EVA foam? You’re in luck! There are actually several methods that can be used to mold EVA foam without the use of a heat gun. In this blog post, we’ll break down some of the most effective techniques, so you can get started on your foam crafting without any extra tools or equipment. From using a household iron to boiling water, we’ll cover it all.

So, whether you’re a beginner or a seasoned foam crafter, keep reading to learn how you can shape EVA foam without a heat gun.

Introduction

When it comes to creating costumes or props, EVA foam is one of the most versatile and cost-effective materials you can use. However, shaping it without a heat gun can be quite a challenge. Don’t worry, though.

There are a few methods you can use to shape EVA foam without a heat gun. One of the easiest ways is to use a sharp pair of scissors or a craft knife to carefully cut and shape the foam. You can also use a Dremel rotary tool with a sanding attachment to sand and shape the foam.

Another popular method is to use a heat source such as a hairdryer or a stove to soften the foam and shape it to your desired form. With a little bit of creativity and patience, you can shape EVA foam without a heat gun and still achieve the look you’re after.

What is EVA Foam?

EVA foam is a versatile and popular material used for a wide range of products, from shoe soles to yoga mats. EVA stands for ethylene-vinyl acetate, a copolymer compound that is soft, flexible, and durable. This material has excellent shock-absorbing properties, making it perfect for use in footwear and sports equipment.

It is also lightweight, waterproof, and resistant to exposure to UV radiation. EVA foam can be customized for various applications, as it is available in different densities, thicknesses, and colors. This means that it can be used for anything, from padding and insulation to crafting and cosplay.

So, whether you need a cushioned floor tile or a foam sword, EVA foam can provide a reliable and affordable solution.

Why Shape EVA Foam without a Heat Gun?

EVA foam, heat gun, shaping Introduction: EVA foam is an incredibly popular material for a wide variety of DIY projects, cosplay, and other crafting ventures. One of the biggest challenges when working with EVA foam is shaping it to fit the desired design. Many people assume that a heat gun is necessary to shape EVA foam, but this is not always the case.

There are a variety of other methods you can use to shape EVA foam, each with its own unique benefits and drawbacks. In this blog post, we’ll take a deep dive into why you might choose to shape EVA foam without a heat gun and explore some of the alternative options available to you. One of the primary reasons someone might want to shape EVA foam without a heat gun is safety.

Heat guns can be incredibly dangerous if not used properly and can cause severe burns, fires, or other accidents. By choosing an alternative method for shaping EVA foam, you can minimize the risk of accidents and keep yourself safe. Additionally, using a heat gun can be time-consuming, especially if you are working on a large project.

By utilizing other shaping techniques, you can save time and energy while still achieving great results. Another reason to shape EVA foam without a heat gun is the level of precision it allows. For example, if you are trying to create intricate details or small shapes, using a heat gun can be challenging.

Alternative shaping techniques, such as using a Dremel rotary tool or a hot knife, can give you a lot more control and allow you to shape small areas with greater accuracy. Additionally, using alternative methods can give your EVA foam a unique texture or finish, which can be difficult to achieve with a heat gun. In conclusion, while using a heat gun is a popular way to shape EVA foam, it is not the only option available to you.

Shaping EVA foam without a heat gun can be safer, quicker, and more precise, and can result in a unique finished product. So next time you are working with EVA foam, consider trying one of the alternative shaping techniques available and discover a whole new world of possibilities!

Methods of Shaping EVA Foam without a Heat Gun

If you’re using EVA foam for cosplay or crafting, you may not have a heat gun on hand to shape it. Luckily, there are several alternative methods you can use. One option is to use a hair dryer on high heat to warm the foam and make it more pliable.

Another is to use hot water – simply heat up a pot of water and dip your foam in for a few seconds at a time, then shape it however you like. You could also try using a clothes iron on a low heat setting – just be sure to protect the foam with a layer of parchment paper or cotton fabric. If none of these options work for you, you can always try shaping the foam by hand with a bit of elbow grease and some scissors or a craft knife.

While a heat gun may be a convenient tool for shaping EVA foam, it’s certainly not the only option you have!

Cutting and Carving with a Knife

When it comes to crafting with EVA foam, there are a few methods to shape it without the use of a heat gun. One key technique is cutting and carving with a knife. Using a sharp utility knife, you can easily create clean edges and precise shapes.

It’s important to use a sharp blade and work slowly and carefully, especially when cutting intricate designs or details. Another tip is to make sure your work surface is protected to prevent damage to both the foam and the workspace. With a bit of practice and patience, cutting and carving with a knife can be a highly effective way to shape EVA foam for your next cosplay or crafting project.

Just be sure to take all necessary safety precautions, as knives can be dangerous if not used properly.

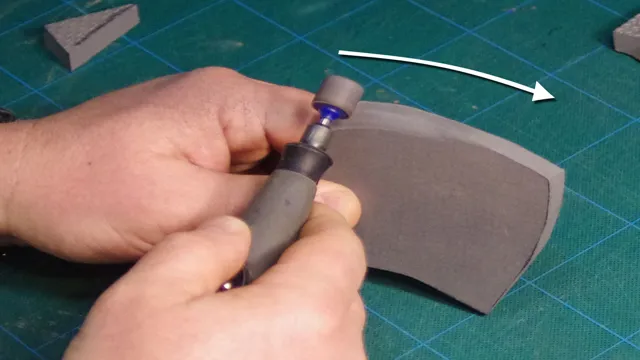

Shaping with a Dremel

Dremel If you’re looking to shape EVA foam without a heat gun, a Dremel is a fantastic tool to have. One method of shaping foam with a Dremel involves using a sanding drum attachment to remove larger amounts of material quickly. Another technique is to use a sanding disc or rotary rasp to shape and carve more intricate details.

However, it’s important to wear protective gear such as goggles and a mask to avoid inhaling foam dust. Before you start shaping, it’s recommended to sketch out your design on the foam and make a rough cut with a utility knife. From there, you can use the Dremel to refine the shape and create fine details.

With a little practice, you can achieve professional-looking results that will impress even the most discerning cosplayers.

Bending with Boiling Water

EVA foam is an excellent material for creating cosplay costumes, props, and other DIY projects. While a heat gun is usually the go-to tool for shaping EVA foam, there are other methods that you can use if you don’t have one on hand. One such technique involves boiling water.

By immersing your foam in hot water, you can make it pliable and bend it into the desired shape. Just be careful not to use boiling water or keep the foam immersed for too long, as this may cause it to lose its shape or even melt. Once you’ve bent your foam, you can then shape it further by using objects such as a rolling pin, a bowl, or a rounded surface to mold it into the desired shape.

With a little bit of patience and experimentation, you can create amazing shapes without the need for a heat gun!

Molding with a Vacuum

If you are looking to shape or mold EVA foam without a heat gun, vacuum molding may just be the solution you need. This method of shaping involves using a vacuum to suck the foam down onto a shape or form, creating a molded piece of foam that conforms perfectly to your desired shape. This process is efficient, effective, and produces high-quality results.

What’s more, vacuum molding can be ideal for cases where heat may damage the foam, making it a valuable technique to have in your arsenal. By using this technique, you can experiment with different shapes and designs without worrying about compromising the structural integrity of the foam. So, give vacuum molding a try and enjoy the limitless possibilities it provides for shaping EVA foam.

Tips and Techniques for Shaping EVA Foam

If you don’t have a heat gun, there are still plenty of ways to shape EVA foam to suit your needs. One technique involves using hot water. Simply heat up a pot of water and remove it from the stove.

Then, dip your foam into the hot water, holding it there for a few seconds until it softens. Once it’s pliable, you can shape it however you’d like. Another way to shape EVA foam without a heat gun is to use a flat iron or hair straightener.

Just set it to a low heat, clamp it onto the foam, and slowly move the iron back and forth until the foam softens enough to be shaped. Be sure to use a pressing cloth to protect the foam from direct heat. With these easy techniques, you can shape EVA foam without relying on a heat gun.

Safety First

As with any craft or project, safety should always be a priority when working with EVA foam. Before you start, make sure you have the necessary protective gear, including eye protection, gloves, and a dust mask. It’s also important to work in a well-ventilated area to avoid breathing in any fumes or chemicals.

When cutting and shaping EVA foam, use a sharp blade and take your time to avoid any accidental slips. It’s helpful to use a cutting mat to protect your work surface and keep your cuts precise. And remember, always follow manufacturer instructions and guidelines when working with any new materials.

By prioritizing safety, you can ensure a successful and enjoyable foam shaping experience!

Choose the Right Tools

When working with EVA foam, having the right tools can make all the difference in achieving the desired shape and finish. Firstly, a heat gun is a critical tool in shaping EVA foam. It allows you to soften and mold the foam, making it easier to shape into the desired form.

A sharp utility knife is also essential for cutting the foam cleanly and accurately. However, it is important to be cautious while using a sharp knife as it can cause injury. Another useful tool is a Dremel tool, which can be used for sanding and smoothing the foam.

Additionally, having a hot wire cutter is ideal for creating intricate curves and shapes. With these tools, you can manipulate EVA foam to create incredible works of art, costumes, and props that will impress anyone who sees them.

Use Templates and Patterns

When it comes to working with EVA foam, using templates and patterns is an essential technique to master. Not only does it save time and increase efficiency, but it also ensures accuracy and consistency in your projects. Templates and patterns can be created by tracing the outline of the desired shape onto a paper or cardboard, or by using computer software to design and print out templates.

These templates can then be used to trace the outlines onto the foam, providing a guide for cutting, shaping, and gluing. By using templates and patterns, you can also easily replicate a design for multiple projects, ensuring a cohesive and professional look. So next time you’re working with EVA foam, don’t forget to utilize this helpful technique for a smoother and more successful project.

Make Strategic Cuts

When it comes to working with EVA foam, one of the most important skills to master is making strategic cuts. This means taking a thoughtful approach to trimming the material in order to create the desired shape and structure. It’s essential to have a sharp cutting tool, such as a box cutter or precision knife, and to work slowly and carefully to avoid mistakes.

You may also want to use a template to guide your cuts and ensure consistency across multiple pieces. Remember, practice makes perfect when it comes to EVA foam cutting, so don’t be afraid to experiment and try different techniques until you find what works best for you. By mastering this skill, you’ll be able to create a wide variety of stunning and professional-looking projects that showcase the versatility and beauty of this amazing material.

Sand and Smooth the Edges

When working with EVA foam, one of the most important steps in shaping your creation is to sand and smooth the edges. This not only makes your piece look more professional and polished, but it also prevents any rough or sharp edges from potentially harming the user. Start by using a medium-grit sandpaper to shape and contour the edges, focusing on removing any rough spots or bumps.

When you’re happy with the shape, move onto a finer-grit sandpaper to smooth out the surface and create a seamless finish. Don’t forget to pay attention to any intricate details or hard-to-reach areas! Alternatively, you can also use a rotary tool with sanding attachments for more precise and efficient sanding. Always wear a dust mask and work in a well-ventilated area to avoid any potential health hazards.

With these tips and techniques, you’ll be able to sand and smooth the edges of your EVA foam creation to perfection.

Conclusion

So, to summarize, shaping Eva foam without a heat gun is possible and not as intimidating as it may seem. By utilizing basic household items like an iron or boiling water, you can achieve the desired shape for your foam project without breaking the bank. It may take a bit of trial and error, but with persistence and creative thinking, you can get the job done.

After all, as they say, where there’s a will, there’s a way – and where there’s foam, there’s always a solution!”

FAQs

Can I shape Eva foam without a heat gun?

Yes, you can use a hairdryer or hot water to shape Eva foam.

How do I shape Eva foam with a hairdryer?

Hold the hairdryer on the highest setting and over the foam, move it around until it becomes pliable, then use your hands or tools to shape it.

Is hot water a good option for shaping Eva foam?

Yes, hot water can help make Eva foam flexible, dip it into the water for a few seconds, remove it, and shape it.

How long does it take Eva foam to cool down after shaping?

It typically takes about 10-15 minutes for Eva foam to cool down completely after shaping.

Can I sand Eva foam after shaping it?

Yes, you can sand Eva foam after it cools down, but use fine-grit sandpaper and be gentle to avoid damaging the foam.

What kind of tools can I use to shape Eva foam?

You can use a craft knife, scissors, a heat cutter tool, or even a Dremel tool to shape Eva foam.

Can I reshape Eva foam after it has cooled down?

Yes, you can reheat Eva foam and reshape it several times.