Are you planning to take up woodworking as a hobby? If so, one of the essential tools that you should learn to use is a jointer. It’s a versatile machine that helps to create flat, smooth, and straight edges on lumber, which is critical for making any woodworking project successful. But setting up a jointer can be intimidating, especially if you’re a novice.

Don’t worry; in this article, we’ll guide you through the process of setting up a jointer step by step. We’ll cover everything from assembling the machine to adjusting the knives’ height and fence alignment. By the end of this guide, you’ll have the confidence to set up your jointer and start your woodworking project with ease.

Whether you’re building a bookshelf, a coffee table, or a rocking chair, a jointer can be immensely helpful. So why not master the art of using a jointer and take your woodworking skills to the next level? Let’s dive in!

Introduction

How to Set Up a Jointer If you want to achieve a smooth and flat surface for your woodworking projects, a jointer is a must-have tool in your arsenal. But before you start using it, you need to know how to set it up properly. First, make sure the jointer is on a stable surface and leveled.

Then adjust the infeed and outfeed tables to the correct height and parallel to each other, ensuring that the blades do not touch the tables. Next, adjust the blade height to the correct depth and make sure they are aligned with the outfeed table. Finally, set the fence to the desired angle and position and lock it in place.

Once you have completed these steps, you’re good to go. Always remember to wear the appropriate safety gear, such as goggles and ear protection, and be careful when handling the blades. With a well-set-up jointer, you can now create precise and professional-looking woodwork projects.

Why set up a jointer?

Jointer If you’re new to woodworking, you may wonder why you need to set up a jointer. A jointer is an essential tool for ensuring your wood pieces are square and flat, which is crucial for making quality projects. When wood is not flat or square, it can be difficult to get tight joints, leading to instability and weak spots in your final project.

By setting up a jointer, you can ensure your wood pieces are straight and level, allowing you to achieve a polished finished product. Keep reading to find out more about why setting up a jointer is an essential part of any woodworker’s arsenal.

Tools and Materials

If you’re looking to set up a jointer, there are a few tools and materials you’ll need to get started. First and foremost, you’ll need the jointer itself, though the exact type may vary depending on your specific needs. You’ll also need a set of knives for the jointer, as well as a wrench for changing them out.

Additionally, it’s a good idea to have a power strip or surge protector nearby to ensure you can power the jointer safely. You’ll also need a set of safety goggles and hearing protection for your own safety. Finally, you may want to invest in a jointer push block to help keep your fingers away from the blades while you work.

With these tools and materials in hand, you should be well-equipped to set up your jointer and start working on your projects.

Jointer machine

A jointer machine is an essential tool for any woodworker or carpenter. It is used to straighten and flatten rough lumber, making it perfect for creating furniture, cabinetry, and other wood products. The jointer features a flat table and a cutting head that rotates at high speeds, which allows it to remove high spots and straighten crooked boards.

To use a jointer, you need some essential materials like rough lumber, a planer, and a dust mask to protect you from the sawdust. Without these materials, the jointer machine won’t be as effective. The key to using a jointer machine is to make sure you have a stable surface to work on and that the board is held in place firmly.

Overall, a jointer machine is an indispensable tool that can help woodworkers transform rough lumber into beautiful, flat boards, making their projects look stunning.

Push blocks

When it comes to building structures with push blocks, having the right tools and materials is crucial to ensure a quality finished product. Firstly, you’ll need push blocks – these are typically made of wood or plastic and are used to apply pressure to the blocks being pushed. You’ll also need a mallet or hammer to help drive the blocks into place, as well as a spirit level to ensure the structure is level.

It’s important to have good quality building blocks as well, so make sure to source these from a reputable supplier. Additionally, having a trowel handy is a good idea, as this will allow you to smooth out any rough spots. With the right tools and materials, building with push blocks can be a fun and rewarding experience, resulting in a durable, long-lasting structure that you can be proud of.

Safety goggles

As a DIY enthusiast or professional tradesman, there are certain tools and materials that are essential for a safe and successful working environment. One of the most crucial items that should always be on your list is a pair of safety goggles. These protective eyewear devices are designed to shield your eyes from flying debris, harmful chemicals, and other hazardous materials that are commonly found in workshop or construction sites.

They come in different types and sizes to suit different tasks and are made from materials that can withstand impact, heat, and corrosion. Without safety goggles, your eyes could be at risk of injury or irreversible damage, which could affect your health and productivity in the long run. Therefore, investing in a pair of quality safety goggles is not just a matter of compliance with safety regulations; it is also a necessary safeguard for your wellbeing and performance.

Do you use safety goggles when working? If not, what are your reasons for not using them?

Setting up the Jointer

Setting up a jointer might seem intimidating, but with the right steps, it can be a breeze. First, make sure the jointer is placed on a level surface and all screws and bolts are tightened. Next, adjust the infeed table to be parallel with the outfeed table by using a straightedge and adjusting the screws underneath the table.

After that, adjust the fence to be 90 degrees perpendicular to the table by using a square and adjusting the bolts or knobs on the fence. Once everything is set up and aligned, turn on the jointer and make a few test passes to ensure everything is working smoothly. Remember to wear safety goggles and keep your hands away from the cutterhead.

With these simple steps, you can confidently set up your jointer and make clean, precise cuts with ease.

Unboxing and assembling the jointer

Setting up the jointer can be a bit intimidating, especially for those who have never used one before. But fear not! With a little bit of patience and attention to detail, you can have your jointer up and running in no time. The first step is unboxing and inspecting all of the parts to make sure everything is present and accounted for.

Once you’ve done that, it’s time to start assembling the jointer. Follow the instructions carefully, making sure to tighten all screws and bolts securely. It’s also important to make sure the jointer is level, using a level tool to ensure it’s not wobbly or uneven.

Once you’ve completed the assembly, it’s time to test it out. Turn it on, and feed a piece of wood through it to make sure everything is working properly. Remember to always wear the appropriate safety gear, such as eye and ear protection, when using your jointer.

With these simple steps, you’ll be well on your way to using your jointer with confidence and ease.

Step by step guide to setting up the jointer blade

When it comes to setting up a jointer, getting the blades just right is crucial for a smooth and precise performance. Here’s a step-by-step guide on how to do it. First, make sure the jointer is unplugged and turned off before proceeding.

Then, remove the old blades and clean the cutterhead. Check for any nicks or dents that might affect the new blades. Install the new blades one at a time, making sure they’re seated snugly and securely.

Use a straightedge to check for any gaps between the blade and cutterhead, adjusting the height until there’s no visible light between the two. Once both blades are installed and properly adjusted, test the jointer on a piece of scrap wood to ensure everything is working smoothly. Don’t forget to tighten the blade mounting screws and be sure to wear safety equipment throughout the process.

With these tips in mind, setting up your jointer’s blades should be a breeze!

Adjusting the infeed and outfeed tables

When it comes to setting up a jointer, one of the most critical steps is adjusting the infeed and outfeed tables. The infeed table is the surface where the wood enters the jointer, while the outfeed table is where it exits. These tables need to be set up correctly to ensure the wood passes evenly through the blades and comes out straight and smooth.

To do this, carefully adjust both tables until they are level with each other and the jointer’s cutterhead. You can use a straight edge or a level to check for straightness. Once you’ve achieved the correct angle, lock both tables in place.

It’s important to note that you may need to adjust these tables periodically as they can shift over time and with use. Paying close attention to these details will ensure you get the best results from your jointer and keep your woodworking projects looking their best.

Using the Jointer

Setting up a jointer is essential for creating flat and straight boards, and the process can seem daunting for beginners. However, with a little practice, it can be easily done. First, ensure that the jointer is secured to a stable surface and that the knives are sharp.

Make use of the manual that came with the tool for specific instructions on how to adjust the infeed and outfeed tables. Start by adjusting the height of the infeed table, making sure that it is equal to the height of the outfeed table. Then, adjust the outfeed table to ensure that it is perfectly parallel to the jointer knives.

Use a straight edge to check the alignment of both the tables and the knives. Once the tables and knives are set up, you can start feeding the wood through the jointer. With the jointer configured properly, you will achieve an even and smooth cut every time, resulting in a perfect project.

Basic jointing techniques

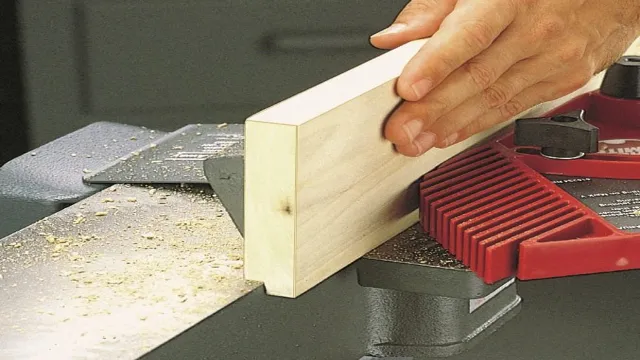

When it comes to basic jointing techniques, using a jointer is one of the most fundamental and efficient methods. A jointer is a woodworking tool designed to create a flat surface edge on a board’s face, allowing for seamless and sturdy connections between pieces. To use a jointer, start by adjusting the machine’s blade height to match the wood’s thickness.

Once the blade is set, feed the wood through the machine, keeping it pressed firmly against the guide fence. The key to making a perfect joint is to take small, shallow cuts, moving the board back and forth until the desired flatness is achieved. Remember to wear protective gear and to never try to take too much off at once.

With some practice and patience, the jointer can become your go-to tool for creating smooth and even edges on your woodworking projects.

Troubleshooting tips

When using a jointer, there are a few troubleshooting tips that can make the experience smoother. Firstly, if you notice that the wood is not sitting flat on the jointer bed, it could be due to an uneven bed. The solution is to adjust the bed until it’s level and parallel to the cutter head.

Another common issue is tear-out, where the cutter head pulls out chunks from the wood instead of creating a smooth cut. In this case, it’s recommended to adjust the cutter head’s depth of cut until you can get a smoother result. Finally, if you notice that you’re not getting a straight edge, it could be due to uneven pressure or alignment.

Make sure that you’re applying consistent pressure throughout the cut and adjust the fence until it’s perpendicular to the jointer bed. By following these simple tips, you can ensure that your jointer will work smoothly and efficiently, without any unexpected surprises.

Conclusion

To set up a jointer is to embark upon a journey of precision and craftsmanship that requires patience, attention to detail, and a sharp eye for symmetry. Like a surgeon preparing for a delicate operation, one must carefully read the manual, adjust the blades and tables with care, and test, test, test until the perfect alignment is reached. And in the end, after all the fine tuning, the jointer will stand as a testament to the power and beauty of human ingenuity – a machine that can transform rough lumber into a smooth, perfectly flat surface that is ready for whatever creative vision one wishes to bring to life.

“

FAQs

What is a jointer and what is it used for?

A jointer is a woodworking tool used to flatten and straighten edges of boards before joining them together.

What are the different types of jointers available in the market?

The different types of jointers include benchtop jointers, floor-standing jointers, helical head jointers, and spiral head jointers.

How to properly set up a jointer before use?

To properly set up a jointer, one needs to ensure the blades are sharp and properly aligned, the fence is square to the table, and the infeed and outfeed tables are level and at the proper height.

What safety precautions should be taken when using a jointer?

Safety precautions when using a jointer include wearing eye and ear protection, keeping hands and clothing away from the blades, and using a push stick to feed the boards through the jointer.

Can a jointer be used to create angled cuts?

Yes, a jointer can be used to create angled cuts by tilting the fence to the desired angle.

How often should the blades on a jointer be sharpened?

The frequency of sharpening the blades on a jointer depends on the usage, but it is recommended to sharpen them at least once a year.

How to troubleshoot common problems that occur while using a jointer?

Common problems that occur while using a jointer include snipe, uneven cuts, and tearout. Troubleshooting involves adjusting the infeed and outfeed tables, tweaking the blade alignment, and using better quality boards.