How to Set My Torque Wrench: A Comprehensive Guide for Accurate Results

If you’re new to working with torque wrenches, you might be wondering how to properly set it to get a precise measurement. It may seem confusing at first, but with a bit of guidance, you’ll be able to use your torque wrench like a pro. Imagine that a torque wrench is like a lock.

You need to turn the dial to the correct combination to unlock it. The same goes for your torque wrench. You’ll need to adjust the settings to match the specifications of the job you’re doing.

The first step is to identify the torque specifications for the fastener you’re working with. This information can be found in the owner’s manual for your equipment or by contacting the manufacturer directly. Once you have these specifications, you can set your torque wrench to the correct level.

Think of your torque wrench like a muscle. You want to set it to the appropriate level so that it can perform its task effectively without exceeding the maximum amount of force it’s capable of. Too much force can lead to over-tightening, while too little force can result in equipment failure.

So, how do you actually set your torque wrench to the right level? First, make sure the wrench is at its lowest setting, then turn the handle until you reach the desired level. Once you’ve set it, lock it in place to prevent any accidental adjustments. With these simple steps, you’ll be able to confidently set your torque wrench to the correct level for any job.

Just remember to always check the specifications beforehand, treat your wrench like a lock and muscle, and lock it in place once it’s set. Happy tightening!

Understand Your Torque Wrench

Setting the torque wrench properly is essential to ensure accurate and safe use. Here’s how to set your torque wrench correctly. First, look for the torque specifications provided by the equipment manufacturer.

Then, adjust the wrench to the desired torque setting by rotating the handle or hand grip until the desired torque value is indicated. It’s always a good practice to test the calibration of the wrench and make adjustments if necessary before use. Always keep in mind that over-tightening or under-tightening can damage the equipment, cause accidents, and result in costly repairs.

So, investing some time and effort in understanding your torque wrench and setting it correctly is undoubtedly worth it in the long run.

Types of Torque Wrenches

If you’re a DIY enthusiast or working in the industry, you know how essential a torque wrench is. It’s a tool that measures and applies the correct amount of torque on nuts and bolts to prevent under or over-tightening, which could cause damage or even danger. There are three primary types of torque wrenches available on the market: click-type, beam-style, and digital.

The click-type torque wrench uses a clicking sound to indicate when the desired level of torque is achieved. The beam-style torque wrench, on the other hand, uses a calibrated beam and pointer to show how much torque is applied. Finally, a digital torque wrench provides a reading as a digital display that is more accurate than the other two types.

Understanding the differences between these wrenches is crucial in choosing the right one for a particular job. Additionally, it’s crucial to keep your torque wrench clean, well-oiled, and calibrated so that it can maintain its accuracy for many years to come.

Why Torque is Important

Torque Without a proper torque wrench, understanding how important torque is may be a challenge. Torque refers to the amount of force used to turn an object or tighten a bolt, and it is essential for ensuring that your tools, machines, and vehicles function correctly. Using too little torque will result in an incomplete connection, increasing the risk of parts coming loose.

On the other hand, using too much torque can cause damage to parts and even cause them to break. In essence, torque is an essential part of the safety and function of the things we use every day. If you are not familiar with how to use a torque wrench, it is time to do some research and learn, so you can ensure that your tools and machines work effectively and safely.

So, remember, torque is essential, and the right amount of it is crucial.

Calibrating Your Torque Wrench

Calibrating your torque wrench is an essential part of keeping it in good working condition and ensuring accurate measurements. If you’re not familiar with how to calibrate your wrench, it may seem like a daunting task at first. However, with some practice and patience, you can become a pro at it in no time.

Understanding your torque wrench is crucial, as it’s used to determine the amount of force required to tighten bolts and nuts on a specific piece of equipment. It’s essential to know what range of torque values you need to achieve and how to adjust your wrench to reach those values accurately. By doing so, you can prevent damage to your equipment and ensure that it functions at optimal levels.

Remember that not all wrenches are made equal, and each one comes with its specific calibration instructions. Therefore, it’s vital to read the manual carefully and follow the manufacturer’s instructions when calibrating your torque wrench. By taking the time to understand your tool and calibrating it correctly, you can rest assured that you’re getting accurate and reliable results every time.

Setting Your Torque Wrench

If you’re wondering how to set your torque wrench, don’t worry, it’s not as complicated as it may seem. First, determine the desired torque value based on the manufacturer’s specifications or a reference chart. Next, adjust the torque wrench to the correct setting by turning the handle or knob to the desired value.

It’s important to ensure that the calibration is accurate before use to avoid under or over-tightening bolts or nuts. To do this, use a torque tester and check the readings against the settings on the wrench. Once you’re confident that the torque wrench is set correctly, you’re ready to use it.

Remember to always use the right torque for the application and regularly calibrate your wrench to maintain accuracy. With a little bit of practice and know-how, you’ll be able to set your torque wrench like a pro in no time.

Find the Torque Specification

Setting your torque wrench can be a daunting task, but finding the proper torque specification is the first step. Most manufacturers provide torque specifications for various fasteners in the owner’s manual or service manual. If you don’t have a manual handy, you can try searching online for the specification specific to your make and model of vehicle.

Once you’ve found the specification, make sure you are using the correct type and size of torque wrench for the job. It’s also important to double-check that you’re using the appropriate socket or bit for the fastener you’re tightening. Taking the time to properly set your torque wrench will not only save you time and headaches down the road, but it will also help ensure the safety and reliability of your vehicle.

Set the Torque Value

Setting the torque value on your torque wrench is a crucial step to ensure the correct tightness of the bolts or nuts. The first thing you need to do is to check the torque specification of the task you’re working on. Once you know this, adjust the torque value on your wrench accordingly.

To do so, use the adjustment mechanism located on the handle and turn it in the desired direction until you reach the designated value. Keep in mind that over-tightening or under-tightening bolts can lead to damage or failure. As a simple comparison, imagine driving a car with overtightened lug nuts.

It would feel like you’re dragging the anchor of a ship behind you. On the other hand, loose lug nuts can cause the wheels to fall off while driving, which is a catastrophic event. Therefore, always ensure that your torque wrench is set to the correct value before you start tightening bolts or nuts.

Use the Locking Mechanism

When it comes to using a torque wrench, it’s important to make sure you’re setting it properly before use. One key step in this process is utilizing the locking mechanism. This ensures that the torque you set stays consistent throughout your task, reducing the risk of over-tightening or under-tightening.

Setting your torque wrench can be done with ease by using the locking mechanism, which helps keep the wrench at the desired setting while you work. This is important to pay attention to, as many professionals in the automotive industry have seen improperly set torque wrenches cause costly damage to valuable equipment. So, to avoid unnecessary repairs and ensure proper functionality, make sure to use the locking mechanism when setting your torque wrench.

Using Your Torque Wrench

If you’re working on a project that requires you to use a torque wrench, it’s important to know how to set it. The first step is to determine the correct torque setting for the particular bolt or nut you’re working on. This information can usually be found in your owner’s manual or online.

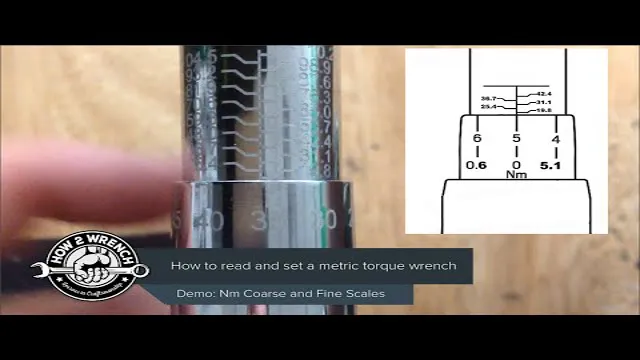

Once you have the correct torque setting, set your torque wrench to that level. Make sure the wrench is properly calibrated and set to the correct unit of measure, whether that be pounds per square inch (PSI), newton-meters (NM), or foot-pounds (ft-lbs). Then, attach the socket to the torque wrench and apply even pressure to the bolt or nut until you hear or feel a click.

This indicates that you’ve reached the correct torque level. Finally, double-check your work and ensure that everything is properly tightened. By following these steps, you’ll be able to use your torque wrench with ease and precision, ensuring that your project is completed accurately and safely.

Correctly Tightening Bolts

Correctly tightening bolts is essential for keeping equipment and machinery running smoothly and for preventing accidents. One of the best ways to ensure proper bolt tightness is to use a torque wrench. A torque wrench is a specialized tool that measures the amount of force used to tighten a bolt.

By using a torque wrench, you can apply a specific amount of torque to a bolt, ensuring that it is tightened to the manufacturer’s specifications. This is particularly important in industries such as construction and manufacturing, where heavy machinery is used and safety is a top priority. By using a torque wrench, you can also prevent bolts from becoming over-tightened, which can cause them to break or strip.

So, if you want to make sure your equipment and machinery are running smoothly, consider using a torque wrench to correctly tighten your bolts.

Cleaning and Storing Your Torque Wrench

When it comes to using your torque wrench, it’s essential to follow the manufacturer’s instructions carefully. Not using it correctly can lead to inaccurate torque readings, and you’ll end up with bolts that are either too loose or too tight. Before using the wrench, ensure that the bolts and nuts are clean and free of any debris or rust.

When it’s time to clean and store your torque wrench, it’s crucial to remove any dirt or grime that may have accumulated on its surface. A clean wrench will not only perform more accurately, but it will also last longer. When storing your wrench, always store it in a dry and cool place away from heat and direct sunlight.

Using a torque wrench might sound intimidating for someone who has never done it before, but it’s pretty straightforward. Follow the manufacturer’s instructions, keep it clean, and store it properly, and you’ll be able to use it efficiently for years to come.

Conclusion

In conclusion, setting your torque wrench is a critical step in ensuring accurate and consistent results. With precision being the name of the game, make sure to consult your manufacturer’s manual and triple-check your settings before applying any torque. Remember: a loose bolt might lead to disaster, while an overtightened nut might lead to a headache.

So, find that sweet spot and tighten like a pro with your trusty torque wrench. Happy tinkering!”

FAQs

What is a torque wrench and why is it important to use one?

A torque wrench is a tool that measures and applies a specific amount of torque to a bolt or nut. It is important to use a torque wrench to ensure proper tightening and prevent damage to parts or equipment.

How do I determine the correct torque setting for my wrench?

The correct torque setting can usually be found in the equipment’s manual or by contacting the manufacturer. Alternatively, online torque specification databases can be useful for finding the right setting.

What are the different types of torque wrenches and how do they work?

There are several types of torque wrenches, including beam wrenches, click wrenches, dial wrenches, and digital wrenches. They all work by measuring the amount of force applied to the wrench and alerting the user when a specific torque value is reached.

How do I calibrate my torque wrench?

Torque wrenches should be calibrated regularly to ensure accurate readings. Calibration can usually be done using a torque calibration tool or by sending the wrench to a qualified calibration lab.

Can I use a torque wrench for loosening bolts or nuts?

No, torque wrenches are designed for tightening bolts or nuts to a specific torque value. Using a torque wrench to loosen bolts or nuts can damage the tool and compromise accuracy in future use.

How can I tell if my torque wrench needs to be replaced?

Signs that a torque wrench needs to be replaced include inconsistent readings, difficulty in using the tool, or physical damage to the wrench.

What safety precautions should I take when using a torque wrench?

Always use the correct torque setting, wear personal protective equipment, and make sure the wrench and equipment are properly secured to prevent accidents or injuries.