Have you ever had to replace a brake bleeder screw on your vehicle but didn’t know where to start? Don’t worry, you’re not alone. Many car owners struggle with this task, but with the right tools and some patience, it can be done easily. In this step-by-step guide, we’ll take you through the process of removing a brake bleeder screw and replacing it with a new one.

Whether you’re a seasoned mechanic or a newbie, you’ll find this guide useful and straightforward. So, grab your tools and let’s get started!

Introduction

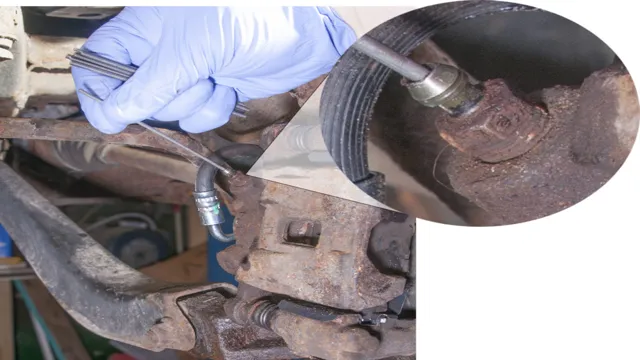

Removing a brake bleeder screw is a relatively simple process, but it is important to do it right to avoid damaging your braking system. First, you need to locate the brake bleeder screw, which is usually located at the top of the brake caliper. You will need to use a proper set of wrenches to remove the screw.

Make sure to choose the correct size of wrench to avoid rounding off the screw. It is also important to use the correct technique when turning the wrench, as excessive force can damage the brake caliper. Once the screw has been loosened, be sure to catch any brake fluid that may leak out using a container.

It is also important to replace the brake bleeder screw with a new one to ensure a proper seal. By following these steps, you can safely and effectively remove a brake bleeder screw without causing any damage to your braking system.

Why You Might Need to Remove a Brake Bleeder Screw

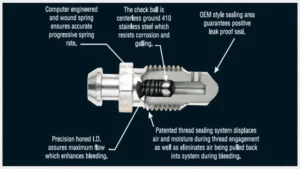

Brake Bleeder Screw Introduction: Brake Bleeder Screw is an essential part of any vehicle. This screw is a threaded valve that helps in removing the air bubbles from the brake lines to achieve better braking efficiency. But sometimes, due to wear and tear or improper maintenance practices, the brake bleeder screw may need to be removed.

In this blog post, we will discuss why you might need to remove a brake bleeder screw and how to do it safely and efficiently to avoid any damage to your vehicle’s braking system. Possible Blog Section h3: “Signs That Indicate The Need to Remove A Brake Bleeder Screw” Signs that Indicate The Need to Remove A Brake Bleeder Screw: Some warning signs may indicate that you need to remove a brake bleeder screw. One of the most common signs is when there is air trapped in the brake lines, making the brake system feel spongy or weak.

In this case, removing the bleeder screw can help get rid of the trapped air, allowing the brake system to function correctly. Another sign is when the brake pedal feels unresponsive or soft, indicating a fluid leak or blockage in the brake lines. Removing the brake bleeder screw can help in identifying the exact location of the problem and finding a suitable solution.

Finally, if the brake bleeder screw is damaged, rusted, or corroded, it may be necessary to remove and replace it to prevent any further damage to the brakes or the entire vehicle’s hydraulic system. In conclusion, removing a brake bleeder screw is not something that should be taken lightly. If you notice any signs of damaged or blocked brake lines, it is crucial to have your vehicle inspected by a professional mechanic or do it yourself using the correct equipment.

Remember to exercise caution and follow the proper safety practices to avoid any accidents or damage to your brake system. By doing this, you can ensure that your vehicle’s braking mechanism functions correctly and provides a safer driving experience.

Materials Needed

When it comes to starting a new DIY project, one of the first things you need to consider is the materials you will need. The specific materials required will depend on the project at hand, but there are a few basics that are necessary for almost every task. These include items like measuring tools (such as a ruler or tape measure), cutting tools (like a handsaw or power saw), and fasteners (like screws, nails, and bolts).

Other materials you may need depending on your project include wood, metal, plastic, paint, hardware, and adhesives. It’s important to plan ahead and make a list of everything you’ll need before you start to ensure you have everything necessary to complete your project.

Step 1: Prepare Your Car for the Job

When it comes to removing a brake bleeder screw from your car, there are a few steps you need to take in order to prepare your vehicle properly. First, make sure you have all the necessary tools on hand, including a wrench or socket that fits your bleeder screw, as well as a brake bleeder kit if needed. Next, jack up your car and secure it on jack stands to ensure stability and safety while working.

It’s also important to remove the wheels from the affected brake system to gain access to the bleeder screw. Finally, use an appropriate penetrating oil, such as WD-40 or Liquid Wrench, to soak the bleeder screw for several hours before attempting to remove it with your wrench or socket. By taking these steps, you can ensure that you are properly prepared to remove the brake bleeder screw from your car without causing any damage or injury in the process.

Locate the Brake Bleeder Screw

To begin the process of bleeding your car’s brakes, the first step is to prepare your vehicle for the job. This involves locating the brake bleeder screw, which is usually found on the brake caliper or wheel cylinder. The brake bleeder screw is a small valve that, when opened, allows air to escape from the brake lines.

It’s important to identify the correct screw, as there may be multiple screws or valves on your vehicle that look similar. A good way to locate the brake bleeder screw is to consult your car’s owner manual, which should include diagrams and instructions. When preparing your car, ensure that the brake system is cool and that you have all necessary tools and safety gear, such as a brake bleed kit, a wrench, protective gloves, and eye goggles.

By taking time to prepare properly, you’ll be able to complete the brake bleeding process safely and effectively, ensuring optimal braking performance.

Protect Surrounding Areas

When it comes to detailing your car, it’s important to take steps to protect the surrounding areas. You don’t want overspray or splatter from cleaning products to damage your paint job or get on adjacent cars. The first step in this process is to prepare your car for the job at hand.

Start by washing your car thoroughly to remove any dirt or debris that could interfere with the detailing process. Once your car is clean, tape off any areas you don’t want to get wet or coated with cleaning products. This could include your windows, rubber trim, and other delicate areas.

By taking these precautions, you can ensure that your detailing job is a success and that you don’t accidentally damage your car or any nearby surfaces.

Step 2: Loosen the Bleeder Screw

Removing a brake bleeder screw can be done in a few simple steps. Step two involves loosening the bleeder screw, which is located near the brake caliper. Using a wrench, turn the bleeder screw counterclockwise until it is loose enough to turn by hand.

Be careful not to force it too much or it may break off. The purpose of loosening the bleeder screw is to allow air and brake fluid to escape from the brake system, which is necessary for proper bleeding. It is important to keep in mind that removing the bleeder screw is not the same as opening it completely.

You just need to loosen it enough to allow a small amount of air to escape. Once you have achieved this, move on to the next step in the process.

Choose the Right Tool

When it comes to bleeding your brakes, choosing the right tool makes all the difference. A brake bleeding kit typically includes a hose and a jar to catch the old brake fluid. Some kits may even come with a hand pump that makes the process even easier.

However, if you don’t have a kit, you can use a simple wrench to loosen the bleeder screw. Keep in mind that the size of the wrench will depend on the make and model of your vehicle. Using the wrong size wrench can damage the screw, making the process even more complicated than it needs to be.

By choosing the right tool, you’ll be able to loosen the bleeder screw with ease, and the brake fluid will start to flow out. Just be sure to keep an eye on the fluid level in the reservoir and add more as needed. Remember, taking your time and using the right tool will help you avoid any problems during the brake bleeding process.

Lefty-Loosey, Righty-Tighty

If you’re new to tinkering with your car’s brakes, loosening the bleeder screw might sound intimidating. But the truth is, it’s a relatively simple process that won’t take too much of your time. To get started, you’ll need a few tools: a wrench that fits the bleeder screw and a container to catch the brake fluid.

Make sure your car’s engine is off and the emergency brake is engaged before proceeding. Using the wrench, turn the bleeder screw counterclockwise, or “lefty-loosey,” until it’s loose. Be gentle so as not to damage the screw.

As the screw loosens, brake fluid will start to trickle out. Place the container directly under the bleeder screw to catch most of the fluid. Remember to dispose of the used fluid properly.

Once you’ve loosened the bleeder screw, you can move on to the next step in diagnosing and fixing your brake issues.

Step 3: Remove the Bleeder Screw

Removing the brake bleeder screw is the next step in the brake bleeding process. The bleeder screw is what allows air to escape from the brake system along with the old brake fluid. To remove the bleeder screw, you will need the appropriate size wrench or socket.

It’s crucial to use the proper tool to prevent stripping the screw, which can lead to more significant issues down the road. When removing the brake bleeder screw, it’s also important to inspect it for signs of wear or damage. If the screw appears to be damaged, it’s best to replace it during the brake bleeding process to ensure the brake system’s proper functioning.

With the bleeder screw removed, you can move onto the next step in the brake bleeding process. Remember to take your time and be gentle when removing the brake bleeder screw to avoid any complications.

Be Gentle and Consistent

When it comes to removing the bleeder screw from your brake caliper, it’s important to approach the task with gentleness and consistency. This is because the bleeder screw is a delicate component that can easily break or strip if you use too much force. Start by ensuring that your wrench or socket is properly aligned with the bleeder screw before you attempt to turn it.

Then, turn the wrench slowly and steadily, using a gentle but firm grip. If the screw doesn’t budge, don’t try to force it – instead, apply some penetrating oil and wait a few minutes before trying again. Remember, consistency is key – keep turning the wrench until the bleeder screw is completely removed, even if it takes a little longer than you expected.

By approaching the task with gentleness and consistency, you’ll ensure that your brake caliper is properly maintained and will continue to function effectively for years to come.

Avoid Using Too Much Force

When it comes to removing the bleeder screw, it’s important to remember that using too much force can cause damage to the screw or the surrounding components. The last thing you want is to strip the threads or break off the screw, making the job even more difficult. Instead, apply firm but gentle pressure, using a wrench to turn the screw in a counterclockwise direction.

If you encounter resistance, stop and take a closer look to make sure you’re not applying too much force or damaging anything in the process. With a steady hand and a little patience, you should be able to remove the bleeder screw without any issues. Remember, it’s always better to take your time and be gentle rather than rush and end up causing more problems.

Step 4: Inspect and Replace

If you’ve followed the first three steps of bleeding your brakes correctly, but you still have a spongy brake pedal, it may be time to inspect and replace the brake bleeder screw. But how do you remove it? First, make sure to use a proper-sized wrench to avoid stripping the screw. Then, gently turn the bleeder screw counterclockwise until it’s loose enough to remove.

Take note of any signs of wear or corrosion on the screw, as these can affect brake performance and require replacement. If the bleeder screw is damaged, you’ll need to replace it with a new one to ensure proper brake performance. Remember to tighten the new screw to the manufacturer’s recommended torque specifications to prevent leaks and ensure safety when driving.

By inspecting and replacing the brake bleeder screw when needed, you can ensure your brakes are performing at their best.

Check for Damage or Wear

When it comes to maintaining your equipment, checking for damage or wear is an essential step. Whether you’re dealing with household appliances or heavy machinery, regularly inspecting your gear for potential faults can save you from disaster down the line. Cracks or worn out parts can lead to equipment malfunction and, in some cases, injury or property damage.

Don’t overlook even the smallest signs of wear, such as frayed wires or loose screws. These seemingly minor issues can quickly escalate, causing more extensive damage. If you do come across any damaged components, don’t try to patch them up yourself instead, replace them with the appropriate part to ensure your equipment functions correctly.

This way, you’ll avoid costly repairs and reduce the risk of future accidents. So next time you’re inspecting your equipment, keep an eye out for any signs of damage or wear and be sure to replace any faulty parts promptly.

Replace if Necessary

When inspecting your device, it’s important to check whether any components need to be replaced. Some of the parts that commonly require replacement include batteries, filters, and cables. If any of these components are worn out or damaged, it’s crucial to replace them to ensure optimal performance and prevent further damage to your device.

Not replacing these parts in a timely manner can cause further issues, leading to costly repairs or even the need to replace the entire device. So, if you notice any signs of wear and tear, don’t hesitate to replace the components in question. By doing so, you’ll extend the life of your device and avoid additional expenses down the line.

Remember, a stitch in time saves nine- and replacing worn-out components can save you a lot of headaches in the long run.

Conclusion

Removing a brake bleeder screw may seem like a daunting task, but with the right tools and techniques, it can be accomplished with ease. First, grab a wrench that fits the screw snugly, ensuring that it won’t slip and cause damage. Next, apply penetrating oil to loosen any rust or debris that may be holding it in place.

Then, gently turn the wrench counterclockwise, being careful not to strip the screw. Finally, remove the screw and revel in the satisfaction of a job well done. Remember, the key to success is patience and persistence – just like in life, sometimes you need to apply a little pressure to get things moving!”

Cleaning Up and Testing Your Work

After completing your construction project, you must inspect and replace any damaged items before moving onto the testing phase. Careful inspection is essential to ensure all components are working correctly and meet safety standards. Check for any loose fittings, damaged cables, or cracked parts.

These flaws can cause serious problems and may even lead to injury or property damage. Replace any defective or worn-out components immediately to prevent problems down the line. Think of it as giving your work a final tune-up, like checking the oil in your car before going on a long drive.

By taking these steps, you can feel confident in the quality of your work and rest assured that you’ve done everything you can to ensure a safe project.

When to Seek Professional Help

When it comes to inspecting and replacing parts of your appliances or HVAC system, there are times when seeking professional help is necessary. For one thing, if you are unsure of how to properly inspect or replace a part, it is better to err on the side of caution and call in an expert. Additionally, if you have already attempted to fix the issue and it persists, it may be indicative of a larger problem that requires the attention of a professional.

Finally, if you notice any signs of damage or wear and tear during your inspection that are beyond your scope of expertise, it is best to let a professional handle the job to ensure it is done properly. Remember, while it may be tempting to try and save some money by doing things yourself, the potential costs of a mistake or improper repair far outweigh the initial savings. So don’t be afraid to ask for help when you need it!

FAQs

What is a brake bleeder screw and why is it important?

A brake bleeder screw is a small valve that releases air from the brake system. It is important because air in the brake lines can cause decreased braking performance or complete brake failure.

How do I know when I need to replace my brake bleeder screw?

If you notice that your brakes are less responsive or are making strange noises, it could be a sign that you need to replace your brake bleeder screw.

Can I remove the brake bleeder screw without affecting the rest of the brake system?

Yes, you can remove the brake bleeder screw without affecting the rest of the brake system. However, you should be careful not to damage the brake line or other components while removing the screw.

What tools do I need to remove a brake bleeder screw?

You will need a wrench or socket that fits the size of the bleeder screw, as well as a container to catch any brake fluid that may spill out.

How do I remove a stripped brake bleeder screw?

If the brake bleeder screw is stripped, you may need to drill it out or use a special tool to remove it. It is important to be careful not to damage the surrounding components while removing the screw.

Can I replace the brake bleeder screw myself?

Yes, if you have the proper tools and knowledge, you can replace the brake bleeder screw yourself. However, if you are unsure or inexperienced, it is recommended to have a professional mechanic do it for you.

What do I do if brake fluid leaks out when I remove the brake bleeder screw?

If brake fluid does leak out when you remove the bleeder screw, it is important to catch it in a container and dispose of it properly. You should also inspect the surrounding components to make sure there are no leaks or damage.