How to Measure for Miter Cuts: Tips and Tricks for Accurate Results

If you’re planning on making some mitered cuts for a woodworking project, the success of your final product depends heavily on the accuracy and precision of your measurements. Measuring for miter cuts can be a tricky process, but with the right tools and techniques, you can achieve perfectly cut and fitted pieces every time. Before you start, you’ll need to gather some supplies.

A good quality tape measure is an essential tool for any woodworker, as is a combination square or bevel gauge. You may also want to invest in a miter saw or hand saw to make your cuts. The key to measuring for miter cuts is to take detailed measurements at each step of the process.

Begin by measuring the length and width of the wood you’ll be cutting, and mark your measurements clearly with a pencil. Next, determine the exact degree of angle you’ll need for your miter cut, and use your bevel gauge or combination square to mark the angle on your wood. Remember, precision is essential when it comes to miter cuts.

Take your time and double-check your measurements as you go. Once you’re ready, use your saw to make your cuts, following your measurements carefully. It may take some practice to get the hang of measuring for miter cuts, so don’t be discouraged if your first attempts aren’t perfect.

With a little patience and persistence, you’ll soon be able to master this important woodworking technique and create beautiful pieces that are perfectly fitted and finished.

What are Miter Cuts?

Miter cuts are a type of angled cut used in woodworking and home construction, where two pieces of material are joined together at a corner. Miter cuts can be used to create clean, professional-looking joints in baseboards, crown molding, and picture frames. To measure for miter cuts, you will need to use a speed square to determine the angle of the corner and then transfer that angle to your material.

It’s important to measure carefully and make precise cuts to ensure a tight fit and avoid any gaps in your joint. With a little practice and attention to detail, you can become a pro at measuring and cutting miter joints in no time!

Understanding the Angle

Miter cuts are a term used in carpentry and woodworking, referring to an angled cut made on a piece of wood, often at a 45-degree angle. These cuts are commonly used in creating frames, molding, and decorative trims. It’s important to note that miter cuts need to be precise, with angles that match perfectly.

Even a slight error in miter cuts can result in an uneven finish or an ill-fitting joint. The angle at which the piece of wood is cut is crucial, as it determines how well the two pieces of wood will fit together. To avoid imperfections, it’s essential to use the right equipment, such as a miter saw or a miter box, and to measure the angle accurately before cutting.

Understanding miter cuts takes practice, but once mastered, it adds a professional touch to any project.

Importance of Accurate Measurements

Miter cuts are an important aspect of woodworking that require precise measurements. Essentially, a miter cut is when you cut a material, typically wood, at an angle to form a corner joint. This type of cut is commonly used in projects such as picture frames, cabinetry, and trim work.

Accuracy is crucial when making these cuts because even a slight miscalculation can lead to improper alignment and an uneven joint. You can use a miter saw or a miter box to make these cuts, but whichever tool you choose, it’s important to take your time and double-check your measurements. Don’t rush the process! By making precise miter cuts, you can create high-quality woodworking projects that look professional and last for years to come.

Tools You Will Need

If you are attempting to make precise miter cuts, you will need a combination of tools to get the job done. Some essential tools include a measuring tape or ruler, protractor or angle finder, and a saw. To start, measure the length of the material you are cutting and mark the desired angle with a pencil and protractor.

Next, set your saw to the appropriate angle and make the cut. It’s essential to double-check your measurements before cutting to ensure accuracy and avoid mistakes. Remember that precision is key, and even small errors can result in a poorly fitting joint.

With the right tools and attention to detail, you can achieve clean, precise miter cuts with ease.

Measuring Tape

If you’re planning on doing any type of measurements, then a measuring tape is an essential tool that you’ll need in your arsenal. But before you can start measuring, you need to make sure you have the right gear to do the job! Firstly, you will need the measuring tape itself, which is available in various lengths, ranging from a few feet to over 30 feet. Make sure to choose the appropriate length for your needs.

Additionally, it is wise to have a level and a pencil with you to mark your measurements clearly and accurately. These tools will ensure that you get precise and consistent results each time you use your measuring tape. With the correct tools at hand, your measuring tape will be a valuable addition to your tool kit to help you complete the job successfully.

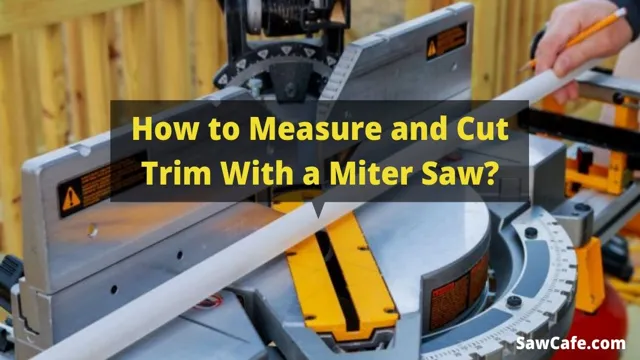

Miter Saw

If you’re planning on using a miter saw for your next woodworking project, you’ll need a few tools to help you get the job done easily and efficiently. First and foremost, you’ll need a good quality miter saw stand or table. This will provide a stable and secure surface to work on, giving you the confidence you need to make precise cuts.

Additionally, you’ll need a sharp saw blade that matches the size of your saw, as well as a dust bag or vacuum designed specifically for miter saws. Other useful tools include clamps, rulers, and pencils to mark your cuts accurately, and safety gear such as goggles and ear protection to keep you safe while using the saw. By having all of these tools on hand, you’ll be well-prepared to tackle any project that comes your way and create beautiful, professional-looking woodwork with your miter saw.

Protractor

Protractor is a powerful automation testing framework widely used for AngularJS applications. One of the primary tools you will need for using Protractor is Node.js, which is a JavaScript runtime that allows you to run code outside of a web browser.

This is because Protractor is based on JavaScript and runs on the Node.js platform. Additionally, you will need Npm, a package manager for Node.

js that is used to install Protractor and its modules. You will also need a Selenium server, which acts as a browser engine and is used for controlling browsers during testing. Lastly, a code editor is necessary for writing and editing your testing scripts, where Visual Studio Code is a popular choice among developers due to its support for TypeScript and Node.

js development. With these tools in place, you will be ready to start automating your AngularJS applications with Protractor and improve the efficiency and accuracy of your testing process.

Step-by-Step Guide

If you want to ensure that your miter cuts are precise and accurate every time, it’s essential to know how to measure for them correctly. The process is relatively straightforward, but it does require some patience and attention to detail. First, you’ll need to determine the angle at which you want to cut.

This is usually either 45 degrees or 90 degrees, depending on the project you’re working on. Once you have the angle, you can measure the length of the piece you need to cut. Be sure to measure twice to ensure accuracy, and then mark the cut line with a pencil or marker.

Finally, carefully align the saw blade with the cut line and make your cut. Remember to take your time and double-check your measurements to avoid any mistakes. By following these steps, you’ll be able to make perfect miter cuts every time and create beautiful, professional-looking projects.

Measure the Length

“Measuring Length” Measuring length accurately is an essential skill that everyone needs to know, whether it’s for DIY projects or professional work. To measure accurately, you need to have the right tools. The most common tool used to measure length is a tape measure.

When using a tape measure to measure length, start by finding the end of the tape measure, then line it up with the edge of the object you are measuring. Next, hold the tape measure in place with one hand and extend the tape measure across the object. Make sure the tape measure remains straight and parallel to the surface you are measuring.

Read the measurement at the point where the tape measure meets the end of the object. Remember to note the unit of measurement, whether it is inches or feet. If you need to measure an object’s circumference, you will need a flexible measuring tape.

Wrap the measuring tape around the object to find the length. Once you have measured the length, write it down or record it to ensure accuracy. With these simple steps, measuring length accurately will be a breeze.

Angle Guide

An angle guide is an essential tool that allows you to make accurate angle cuts when working with wood or other materials. It consists of an adjustable arm that attaches to your saw or other cutting tool, allowing you to set the angle you need for your cut. Using an angle guide is simple, and with a few steps, you can make accurate cuts with precision and ease.

Firstly, you need to determine the angle you need by measuring the angle on the material you’re working with or using a protractor. Then you can attach the angle guide to your cutting tool and adjust the arm to the desired angle. Once set, you can make your cut, knowing that it will be precise and accurate.

With an angle guide, you can take your woodworking or other projects to the next level, allowing you to achieve professional-grade results without the need for specialized skills or experience. So, don’t hesitate to invest in an angle guide! It’ll make your work easier, efficient, and accurate.

Mark the Wood

If you’re a DIY enthusiast and you’re looking to give your wooden project a unique look, then trying out the “Mark the Wood” technique is a fun and easy way to achieve that. This technique involves using a blowtorch to burn the surface of the wood, creating a charred effect that reveals the grain detail underneath. Here’s a step-by-step guide on how to do it: Firstly, you need to acquire all the necessary tools: a blowtorch, sandpaper, and a wire brush.

Secondly, sand the wood to make sure it’s smooth and clean. Then, using the blowtorch, carefully scorch the surface of the wood, moving the flame along the grain to create an even effect. Once you’re happy with the burn, use the wire brush to clean off the surface and smooth out any rough edges.

Finally, sand the wood again to give it a polished finish. The “Mark the Wood” technique may seem tricky at first, but with some practice, you’ll be able to create stunning, one-of-a-kind pieces that are sure to impress.

Double Check

Double Check Double checking is an essential step in any process to ensure accuracy and avoid errors. It can be applicable in different areas, from accounting to medicine, and even in simple day-to-day tasks like sending an email. Without double-checking, there’s always a possibility of missing out on something important, resulting in costly consequences.

To double-check effectively, follow a step-by-step guide. Start with reviewing the task or information you need to verify, then take a break before reviewing it again. This pause helps to clear your mind and bring a fresh perspective.

Use a checklist or a template to help you assess all the details, and always ask questions if there’s something unclear. It’s essential to rely on various sources of information to cross-check the facts, especially if it’s a crucial matter. Once you’re done, review your findings and compare them to your initial assumptions to ensure consistency.

Remember, double-checking is not wasting time but a way to improve the quality of your work and save you from costly mistakes. So, take your time and do it right!

Tips for Accuracy

When it comes to making miter cuts, accuracy is key. Whether you’re cutting baseboards, crown molding, or picture frames, measuring correctly is the first step. To get started, you’ll need a measuring tape, a pencil, and a miter saw.

Begin by measuring the length of the material you’re cutting. Next, determine the angle at which you want to cut. Most miter saws have preset angles, but you can adjust the angle by loosening the saw’s pivot lock.

Once you have the angle set, use your measuring tape to mark the length of the material on the saw’s base. Finally, use your pencil to mark the material at the appropriate length and angle. Keep in mind that it’s always better to cut a little too long than to cut too short.

With a little patience and practice, you’ll be able to make perfect miter cuts every time.

Clear Work Area

A clear work area is essential for accuracy in any task, whether it’s cooking, sewing, or working on a computer. A cluttered or disorganized workspace can lead to mistakes, distractions, and missed opportunities. To ensure accuracy, it’s important to keep your work area clean and tidy.

This means clearing away any unnecessary items, putting away tools and equipment when they’re not in use, and arranging your workspace in a way that makes sense for the task at hand. By taking the time to create a clear work area, you’ll be able to focus better, work more efficiently, and produce higher-quality results. So, if you want to ensure accuracy in your work, start by taking a close look at your work area and making sure it’s as clean and organized as possible.

Your productivity and accuracy will thank you!

Follow Safety Precautions

When it comes to any task that requires precision, taking appropriate safety precautions is essential. Whether you’re working with sharp tools or handling delicate materials, ensuring that you’re following safety guidelines is critical. Not only will it help you avoid accidents and injuries, but it can also improve the accuracy of your work.

For instance, if you’re working with machinery that requires protective gear, wearing the proper equipment will help you maintain focus and reduce distractions. Additionally, if you’re handling materials that require a specific level of cleanliness, using gloves or taking other precautions can help you avoid contamination. By taking the necessary precautions before starting your work, you’ll be able to focus on accuracy without worrying about your safety.

So always remember, safety first!

Take Your Time

When it comes to accuracy, taking your time is key. Rushing through a task is a sure-fire way to make mistakes and overlook important details. So, how can you ensure you’re taking your time without sacrificing productivity? One tip is to break down tasks into smaller, more manageable chunks.

This allows you to focus on each step without feeling overwhelmed. Additionally, taking short breaks can help refresh your mind and increase focus. Don’t be afraid to ask for clarification or double-check your work either.

Taking a few extra minutes to ensure accuracy can save you time in the long run. Remember, accuracy is more important than speed. By taking your time and being thorough, you’ll produce high-quality work that you can be proud of.

As we come to the end of a journey or task, it’s natural to reflect on what we’ve achieved and what we’ve learned along the way. This is where the conclusion comes in, wrapping up all loose ends and presenting a final summation of the topic at hand. While it may seem like a simple step in the writing process, the conclusion is often what leaves a lasting impression on the reader.

It can be the difference between a job well done and a missed opportunity to make a powerful statement. So, what makes a good conclusion and how can we ensure our writing ends on a high note? Let’s explore.

Conclusion

When it comes to measuring for miter cuts, the key is precision and patience. Take the time to accurately measure your materials, factor in the angle of your cut, and use the right tools for the job. And just like a good joke, always remember to measure twice and cut once.

With these tips in mind, your miter cuts will be sharp, precise, and as perfect as the punchline of a well-crafted joke.”

FAQs

What tools do I need to measure for a miter cut?

You will need a measuring tape, a protractor, and a miter saw.

How do I measure the angle for a miter cut?

Place the protractor on the edge of the piece of wood and adjust it until it reads the desired angle.

Can I use a circular saw instead of a miter saw for miter cuts?

Yes, but you will need to use a guide to ensure accuracy.

How do I calculate the length of the wood for a miter cut?

Use the Pythagorean theorem (a² + b² = c²) to find the length of the hypotenuse (c) if you know the length (a) and height (b) of the triangle.

How do I make sure my miter cuts are precise?

Use clamps to keep the wood securely in place and make sure the blade of the saw is sharp.

What is the difference between a miter cut and a bevel cut?

A miter cut is an angled cut made across the face of the wood, while a bevel cut is an angled cut made across the thickness of the wood.

What is the best type of saw blade to use for miter cuts?

A crosscut blade with a high tooth count is best for miter cuts.