Have you ever wanted to learn how to make your own welding machine transformer? Well, look no further! With a little bit of knowledge and some basic electrical components, you can create your own transformer to power your welding projects. This may seem like a daunting task, but with the right guidance and a bit of patience, it is completely doable. In this post, we will walk you through the steps and materials you need to build your own welding machine transformer.

Whether you are a seasoned welder or just starting out, this DIY project is a great way to expand your skills and save some money in the process. So, put on your safety glasses and let’s get started!

Introduction

If you’re interested in welding or metalworking, you may have wondered how to make a welding machine transformer. While it may sound daunting, building your own transformer for a welding machine can be a satisfying and rewarding experience. A welding machine transformer works by step-down voltage conversion, meaning it converts high voltage, low amperage AC power to low voltage, high amperage DC power, which makes it essential for welding.

To make a welding machine transformer, you’ll need to wind insulated copper wire around a magnetic core, which is typically made from laminated steel. The number of turns of wire you need will depend on the power output you desire, so research the best wire-to-core ratio before beginning your project. While this process may take time, creating a welding machine transformer allows you to customize the machine to your specific needs and gain a deeper understanding of how it works.

Explanation of What a Welding Machine Transformer Is

A welding machine transformer is a device that is essential in the process of welding. This transformer is responsible for transforming the input voltage from the power source into the output voltage required by the welding machine. It works by using electromagnetic induction to increase or decrease the voltage, depending on the specifications of the welding job.

The welding machine transformer is an important component of any welding setup as it ensures that the current is regulated to the right levels for effective welding. It is the heart of a welding machine and is responsible for making sure the welding process is as efficient and effective as possible. Without this transformer, the welding machine would not be able to function properly, and the entire welding process would be compromised.

So, if you are interested in welding, it is important to understand the role that the welding machine transformer plays in the welding process.

Overview of Basic Components of a Welding Machine Transformer

If you’re new to welding machines, it can be overwhelming to understand the components that make them work. However, a basic understanding of the transformer in a welding machine is essential for any welder. The transformer is a key component that helps convert the incoming voltage to a more suitable welding voltage.

It’s important to understand that welding machines vary in size and complexity, so transformers can also differ in design. In general, a welding machine transformer consists of two coils of wire wrapped around an iron core. The primary coil, which receives the incoming voltage, is typically wound with fewer turns than the secondary coil.

This design allows for a higher voltage output, which is necessary for welding. To put it simply, the transformer is what allows a welding machine to generate the heat needed for welding.

Step-by-Step Guide to Building a Welding Machine Transformer

If you’re a welder or DIY enthusiast, knowing how to make a welding machine transformer can be a useful skill. Building your own transformer allows you to customize it according to your needs and save money in the process. Here’s a step-by-step guide to help you get started.

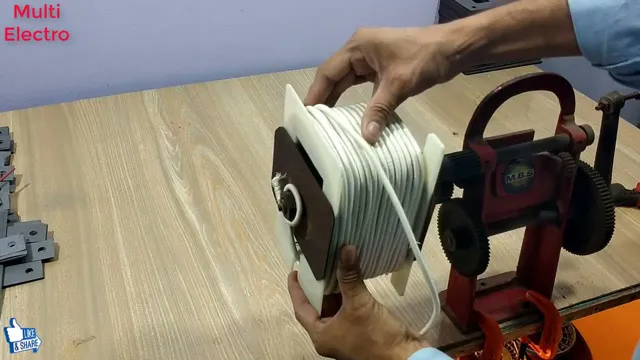

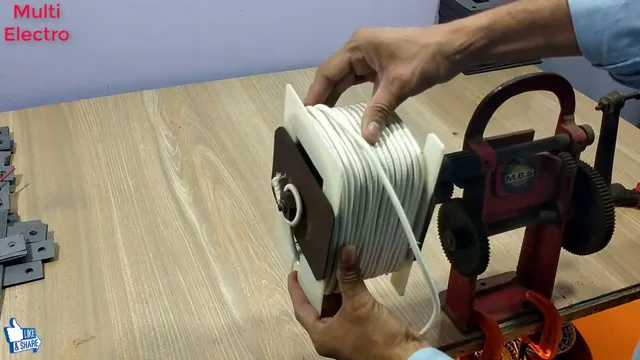

First, gather all the necessary materials such as a steel core, copper wire, and insulation material. Using a winding machine, start winding the copper wire around the steel core. Next, create multiple layers of insulation between each winding to prevent any short circuits.

Once you’re done with the desired number of windings, seal the transformer with an epoxy coating and attach it to the power source. Lastly, use a voltmeter to check the transformer’s output voltage and adjust it as needed. With these simple steps, building your own welding machine transformer is achievable, and you’ll be on your way to creating some impressive welding projects in no time.

Gathering Required Tools and Materials

In order to build a welding machine transformer, you will first need to gather all the necessary tools and materials. The process of acquiring the required equipment can seem overwhelming, but with a little research and preparation, you’ll be able to get everything you need. Some of the essential tools and materials include a steel core, copper wire, insulation paper, lamination stacks, and a few specialized tools like a soldering iron and a resistance wire cutter.

Don’t forget to also acquire safety equipment like welding helmets, gloves, and goggles to keep you protected during the construction process. Once you have everything you need at hand, you can begin the next step of crafting a high-quality welding machine transformer from scratch.

Creating the Core and Winding the Coils

One of the most crucial parts of building a welding machine transformer is creating the core and winding the coils. The core acts as the foundation of the transformer, providing a path for the magnetic field to flow through. To create the core, you’ll need to choose a suitable material such as laminated iron sheets and shape it to the desired size.

The next step involves winding the coils – this is where the power of the transformer comes from. To do this, you’ll need to wrap the core with copper wire, which will serve as the conductor responsible for transferring the electrical energy from the primary coil to the secondary coil. The key here is to achieve consistency in the winding, so the transformer can effectively function.

To ensure precise winding, it’s helpful to use a winding machine or a hand-operated winder. Remember to be patient and diligent during this process, as it lays the foundation for a properly functioning welding machine transformer.

Adding Insulation and Assembling the Transformer

Building a welding machine transformer is an exciting project that requires some technical know-how, attention to detail, and a lot of patience. One of the critical steps in assembling a transformer is adding insulation. This is done to prevent electrical leakage and ensure that the transformer operates safely and efficiently.

You can use various types of insulating materials, including Nomex paper, Kapton tape, and high-temperature epoxy. To add insulation, start by cutting the material into the appropriate shape and size. Then, apply it to the core laminations, making sure that there are no air gaps or wrinkles.

Once you have added insulation, it’s time to assemble the transformer. Start by aligning the laminations and clamping them together. Then, wrap the primary and secondary coils around the core, making sure to keep them tightly wound.

Finally, connect the leads to the terminals and test the transformer to make sure everything is working correctly. With some practice and diligence, you can build a high-quality welding machine transformer that will serve you well for years to come.

Safety Precautions to Take When Making a Welding Machine Transformer

Making a welding machine transformer can be a fun and rewarding project, but it’s important to take safety precautions to avoid injury or damage to your equipment. First and foremost, always wear the appropriate personal protective equipment (PPE), including gloves, goggles, and a mask. It’s also important to work in a well-ventilated area to avoid inhaling harmful fumes.

When working with electrical components, be sure to unplug your equipment and discharge any capacitors to avoid electric shock. Additionally, always follow the manufacturer’s instructions and consult with a professional if you’re unsure about any aspect of the process. By taking these safety measures, you can confidently create a welding machine transformer that will provide reliable and efficient performance.

Explanation of Risks and Hazards Involved in Making a Welding Machine Transformer

When it comes to making a welding machine transformer, there are several risks and hazards involved that need to be considered. One of the biggest risks involves the high voltage that is used in the transformer, which can cause serious injury or death if not handled properly. It is important to take proper safety precautions when working with high voltage, including wearing proper protective equipment like rubber gloves, safety glasses, and a face shield.

Additionally, it is important to ensure that all tools and equipment are properly grounded and to never touch any live electrical wires or components. Other hazards that can arise during the process of making a welding machine transformer include fire and explosion risks. To avoid these hazards, it is important to work in a well-ventilated area and to never allow any flammable materials near the welding area.

By taking these safety precautions and being aware of the risks and hazards involved in making a welding machine transformer, you can ensure a safer and more successful project.

Tips for Avoiding Accidents and Injuries While Working on Your Transformer

When it comes to working on a welding machine transformer, safety should be your top priority. Accidents and injuries can happen when dealing with high levels of electricity, so it’s essential to take precautions to protect yourself and those around you. The first step to ensuring your safety is to use appropriate personal protective equipment (PPE), such as insulated gloves, goggles, and clothing that won’t easily catch fire.

Additionally, always disconnect the power supply to the transformer before working on it. Make sure to follow all safety guidelines provided by the manufacturer and never take shortcuts when it comes to safety. It may seem like a hassle to take all the necessary precautions, but it’s better to be safe than sorry when working on something as potentially dangerous as a welding machine transformer.

Conclusion

In conclusion, creating your own welding machine transformer may seem like a daunting task, but with the right materials and tools, it can be quite an electrifying experience. Just keep in mind that safety is key when working with high voltage and always double-check your calculations to avoid any shocking surprises. And if all else fails, remember that there’s always a spark of creativity in every welder, so don’t be afraid to experiment and let your creativity flow! Happy welding!”

FAQs

What is a welding machine transformer?

A welding machine transformer is a device that steps up or down the voltage of the input electricity to provide the necessary power for welding.

What are the components of a welding machine transformer?

The main components of a welding machine transformer are the primary and secondary coils, the core, and the cooling system.

How does a welding machine transformer work?

A welding machine transformer works by transferring electrical energy from the primary coil to the secondary coil, which then delivers the required welding current to the welding electrode.

What are the benefits of using a welding machine transformer?

The benefits of using a welding machine transformer include improved welding quality, increased efficiency, and reduced energy consumption.

Can a welding machine transformer be repaired if it fails?

Yes, a welding machine transformer can be repaired if it fails. However, it is recommended that repairs be carried out by a qualified technician.

How do I choose the right welding machine transformer for my needs?

The right welding machine transformer for your needs will depend on factors such as the type of welding you will be doing, the thickness of the materials you will be welding, and your power requirements.

Can a welding machine transformer be used with different types of electrodes?

Yes, a welding machine transformer can be used with different types of welding electrodes, depending on the type of welding being done and the materials being joined. However, it is important to select the appropriate electrode for the job to achieve the best results.