Have you ever wondered how to turn an old microwave transformer into a powerful welding machine? Look no further! With a DIY guide and a few tools, you can transform an old, unused transformer into a powerful tool for welding. Welding machines are often very expensive, making it difficult for hobbyists or those on a tight budget to start welding as a hobby or profession. However, with the right knowledge and tools, you can save money and create a customized welding machine that can meet your specific needs.

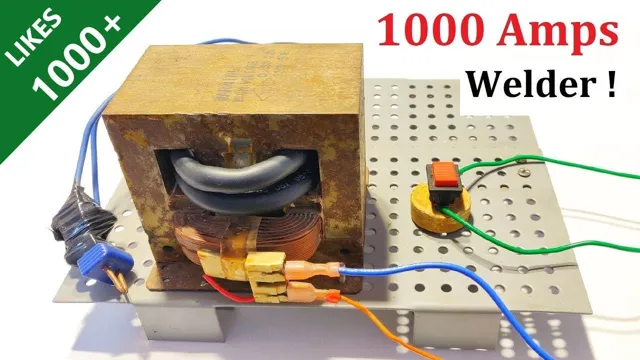

This DIY guide will walk you through the steps to transform an old microwave transformer into a fully functional welding machine. You’ll learn how to create a sturdy frame, install the transformer, and wire all the components to harness the power of the transformer. By using an old transformer and building your own welding machine, you not only save money but also help to reduce waste by repurposing outdated technology.

Plus, you’ll have the satisfaction of creating something yourself and possessing the knowledge to make repairs or upgrades in the future. So, grab your tools and get ready to transform an old microwave transformer into a welding machine that can tackle any job. With this DIY guide, you’ll have the knowledge and skills to create a powerful welding machine without breaking the bank.

Introduction

Have you ever considered making your own welding machine at home? It’s easier than you might think! In this tutorial, we’ll guide you through the process of converting a microwave transformer into a welding machine. A microwave transformer is a handy component to work with, as it provides the high voltage and high current needed for welding. However, it’s important to note that this process can be dangerous if not done correctly.

So, before we begin, make sure you have the necessary safety gear and read through our step-by-step instructions carefully. Let’s get started on how to make a welding machine from a microwave transformer!

Explanation of Basic Components Used

When it comes to understanding the basic components used in various technologies, it’s essential to have a clear understanding of what each one does and how it contributes to the overall functionality. In particular, you may encounter a variety of different components when working with electronics, such as resistors, capacitors, transistors, and integrated circuits, each of which serves a unique purpose. Capacitors, for example, are designed to store electrical energy, while transistors are used to amplify or switch electronic signals.

Meanwhile, resistors are used to regulate the flow of electrical current within a circuit. Ultimately, by understanding the role and purpose of each basic component, you can gain a better understanding of how different technologies work and how to troubleshoot and repair them when necessary.

Safety Precautions to Take

Safety precautions are essential to ensuring a safe environment for everyone. Whether you are at home or at work, there are always risks that need to be addressed. Accidents can happen quickly, and it is important to be prepared.

By taking safety precautions, you can minimize the risk of injury and harm. In this blog post, we will discuss some common safety precautions that you can take to keep yourself and those around you safe at all times. By implementing these tips, you can be sure that you are doing everything possible to stay safe.

So, let’s get started!

Step-by-Step Instructions

If you’re interested in welding but don’t want to spend a lot of money on a professional welder, you can actually make your own welding machine from a microwave transformer. This might sound daunting, but with some patience and careful work, you’ll soon have a functional welding machine that you can use for DIY projects and repairs. To start, you’ll need to carefully remove the transformer from an old microwave, and then clean and prep it for use.

You’ll also need a few other components, such as a rectifier, capacitor, and some wiring. Once you have everything assembled, you can start testing your welder and making adjustments as needed. While making your own welding machine isn’t for everyone, it can be a fun and rewarding DIY project that can save you a lot of money in the long run.

So why not give it a try and see what you can create with your homemade welding machine?

Removing Transformer from Microwave

Removing the transformer from a microwave may sound like a daunting task, but with the right tools and preparation, it can be done easily. Firstly, ensure that the microwave is unplugged and that you are wearing protective gear such as gloves and safety goggles. Locate the transformer, which is usually situated at the back of the microwave.

Identify the connections between the transformer and other components and unscrew them carefully. Remove the screws holding the transformer in place and gently lift it out of the microwave, taking care not to damage any of the wires. It’s important to note that transformers can hold high levels of electricity, so it’s crucial to handle them with extreme care and caution.

By following these step-by-step instructions, you can safely and efficiently remove a transformer from a microwave.

Preparing Transformer for Welding

Transformer, welding Before starting any welding project, preparing the transformer is a crucial step to ensure the safety and efficiency of the welding process. Firstly, it’s essential to inspect the transformer to ensure that it’s in good condition and free of any defects. Check the cables and connections for any loose parts or damage, and replace them if necessary.

Next, adjust the settings on the transformer according to the welding project requirements. You may need to lower or increase the voltage or current depending on the welding material, thickness, and electrode type. Once these adjustments are made, turn on the transformer and wait for it to heat up.

During this time, it’s crucial to wear protective gear such as welding helmet and goggles, gloves, and appropriate clothing. Finally, test the transformer’s output to ensure that it’s functioning correctly, and you’re ready to start welding. Remember to follow all safety procedures and use proper welding techniques to get the best results.

With a well-prepared transformer, you can complete your welding project smoothly and efficiently.

Designing and Making the Welding Circuit

When designing and making a welding circuit, it’s important to follow step-by-step instructions to ensure that everything is set up properly. First, gather the necessary materials, including an ignition switch, a fuse holder with fuse, a battery, and cables. Next, create a circuit diagram to plan the layout and ensure everything is connected correctly.

Once the diagram is complete, begin wiring the circuit, starting with the battery and fuse holder. Connect the cables to the ignition switch, making sure to attach them to the correct terminals. After confirming that all connections are secure, test the circuit to ensure that it’s functioning properly.

A well-made welding circuit can greatly improve the quality and efficiency of your welding work. Remember, safety is key when working with electronics, so always double-check all connections before use.

Testing the Welding Machine

If you’ve successfully turned a microwave transformer into a welding machine, congratulations! The next step is to test it out and see if it’s functioning correctly. The first thing you should do is to check the voltage and amperage levels, making sure they match the recommended settings for the electrodes you’re using. Then, connect the electrodes to the output terminals of the welding machine and turn it on.

Take note of the spark produced and check the welding joint for any signs of proper fusion. If the spark is weak or non-existent, it may be due to loose connections or faulty insulation. You might need to go back and double-check your wiring or replace any worn-out parts.

Keep in mind that welding can be dangerous, so always observe proper safety precautions and wear protective gear. With some trial and error and a little patience, you’ll soon be welding like a pro using your very own DIY welding machine from a microwave transformer.

Checking the Circuit for Errors

As with any significant equipment, it’s important to check that your welding machine is in top working order before using it. Testing the circuit for errors is crucial to ensure that the welding machine works effectively and efficiently. There are various testing mechanisms that you can use to ensure that your machine is working as it should be.

Some of these tests include measuring the voltage of the power outlet, testing the power strip or circuit breaker, and checking the ground connection of your welding machine. Remember that welding machines can be dangerous if they are used without proper safety precautions. You should always wear protective equipment such as gloves, aprons, and helmets to prevent injury.

Additionally, it is essential to understand the proper use and maintenance of your machine. This includes regular cleaning, inspections, and servicing to keep it working optimally. By following these steps, you’ll ensure your welding machine is in great condition and protect yourself from harm while using it.

With regular maintenance, you can extend the life of your equipment and save yourself money in the long run.

Connection to Power

When it comes to welding machines, the connection to power is crucial in ensuring the machine functions properly. Before starting any welding project, it’s important to test your welding machine to ensure it’s receiving the appropriate amount of power. This not only ensures the quality of your weld but also your safety.

To test the welding machine, start by checking the voltage and amperage that the manufacturer recommends. Then, ensure that the welding machine is properly grounded to prevent electrical shock. Once you’ve checked the voltage, amperage, and grounding of the machine, turn it on and ensure that it’s producing the expected spark and heat.

If you’re unsure how to test your welding machine, read the manufacturer’s instructions or consult a professional. Remember, the connection to power is the foundation of a proper weld, so taking the time to test your welding machine is crucial.

Conclusion

In conclusion, turning a microwave transformer into a welding machine may seem like a daunting task, but with a little bit of know-how and some DIY spirit, it’s definitely achievable. Just remember to proceed with caution and ensure that you have the proper safety gear and knowledge before attempting any modifications. With the right tools and a willingness to experiment, you can transform an old microwave transformer into a powerful welding machine that will impress any DIY enthusiast or professional welder.

So get out there and start tinkering – who knows what kind of innovative solutions you can come up with next!”

FAQs

What is a microwave transformer and how is it different from a regular transformer?

A microwave transformer is a type of high voltage transformer used in a microwave oven to step up the voltage from the power outlet to the level required to power the magnetron. It is different from a regular transformer in its design, size, and winding ratios.

Can a microwave transformer be used to make a welding machine?

Yes, a microwave transformer can be used to make a welding machine with some modifications and additional circuitry.

What are the steps involved in making a welding machine from a microwave transformer?

The steps involved in making a welding machine from a microwave transformer are: removing the transformer from the microwave oven, cleaning and preparing it for use, modifying the secondary winding, adding a rectifier circuit and capacitors, and designing a suitable welding electrode holder.

What are the safety precautions to be taken while working with a microwave transformer?

The safety precautions to be taken while working with a microwave transformer are: wearing protective gear such as rubber gloves and safety goggles, ensuring that the transformer is discharged of any residual charge before handling it, avoiding contact with bare wires or terminals, and ensuring that the circuit is properly grounded.

Can a welding machine made from a microwave transformer be used for professional welding applications?

No, a welding machine made from a microwave transformer is not recommended for professional welding applications due to its limited output power and reliability.

What other DIY projects can be done with a microwave transformer?

Other DIY projects that can be done with a microwave transformer include making a high voltage power supply, a tesla coil, an arc welder, a plasma cutter, or a Jacob’s ladder.

What is the cost of making a welding machine from a microwave transformer?

The cost of making a welding machine from a microwave transformer depends on the availability of materials and components, but it is generally cheaper than buying a commercial welding machine. The cost can range from $50 to $200 depending on the quality of the parts used.