Have you ever wanted to try welding but don’t have access to a welding machine? Well, you’re in luck because with the right tools and some helpful guidance, you can make your own welding machine at home. In this PDF guide, we’ll be providing step-by-step instructions and tips on how to make a welding machine that’s safe and effective for your DIY welding projects. Some might feel intimidated by the task of building a welding machine, but fear not, as it’s actually quite doable with some basic knowledge of electrical circuits and some patience.

We’ll be going over the essential electrical components needed for building a welding machine, as well as the different types of welding processes and how they work. We’ll also be covering safety precautions and ways to ensure that your home-built welding machine is reliable and durable. With our guide, you’ll not only be able to save money on buying a welding machine, but you’ll also gain valuable experience in DIY electronics and welding that can come in handy for future projects.

So, grab your tools and let’s get started on crafting your very own welding machine from the comfort of your home. Who knows, you might just become a welding pro in no time.

Introduction

Are you looking for a cost-effective way to create your own welding machine at home? Fortunately, creating a welding machine at home doesn’t require expertise or a great deal of money. One of the easiest ways to create your welding machine is by using a conventional transformer. With just a few simple steps and readily available materials such as a transformer, capacitors, and welding rods, you can build a fully functional welding machine in the comfort of your home.

A helpful guide detailing how to make a welding machine at home PDF is a great place to start your DIY welding machine creation journey. Don’t let expensive welding machines be a barrier to pursuing your welding aspirations. With a little effort and knowledge, you can build your welding machine that meets your specific needs.

Why Make a Welding Machine at Home?

Making a welding machine at home might seem like an unusual hobby for some, but for those who are passionate about welding, it can be a rewarding and practical endeavor. By creating your own welding machine, you get to customize it to fit your specific needs and preferences, which can save you time and money in the long run. Additionally, building your own welding machine can give you a sense of accomplishment and a deeper understanding of how welding machines work.

Plus, if you’re someone who enjoys tinkering with electronics and DIY projects, making a welding machine at home can provide a fun and challenging opportunity to put your skills to the test. So why not give it a try and see what you can create?

What You Will Need

When starting a new project, it’s important to have all the necessary tools at hand. Whether you’re a DIY enthusiast or a professional contractor, having the right equipment can make all the difference. When tackling a new project, you’ll need tools specific to the task at hand.

A hammer, screwdrivers, pliers, level, measuring tape and saw are just the beginning. Depending on the nature of the project, you may also need more specialized tools such as a jackhammer, welding torch, or angle grinder. It’s important to consider the materials you’ll be working with, the size of the project, and your level of expertise to determine the tools you’ll need.

Proper planning and preparation will save you time and frustration in the long run, and ensure that your project is a success.

Designing Your Welding Machine

Making a welding machine at home is not as difficult as it may seem, and with the right guidance, you can design one for yourself. The first step is to gather all the necessary components, including transformers, capacitors, diodes, and resistors. Once you have everything, you’ll need to draw up a diagram to help you arrange the components correctly.

The next step is to connect the components following the diagram, making sure that everything is well-secured and insulated. You’ll also need to select an appropriate welding electrode and connect it to the output terminals. Finally, you need to test your welding machine to ensure that it’s working correctly, and adjust the settings until you’re satisfied with the results.

While designing a welding machine at home may seem challenging, it can be a fun and rewarding project. There are numerous PDF guides available online that can provide you with step-by-step instructions to help you get started. So if you’re up for a challenge and want to save some money in the process, why not try making your welding machine at home today?

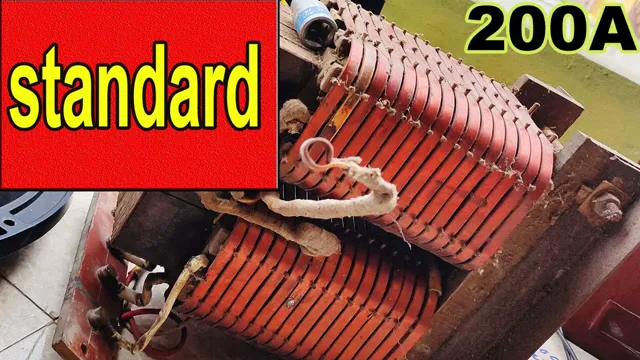

Choosing a Transformer

When designing your welding machine, choosing the right transformer is crucial. The transformer’s main job is to change the voltage and current levels from the input to the output of the welding machine. One of the first things you need to consider when selecting a transformer is the power output required.

This is determined by the size of the welds you need to make and the type of material you will be welding. Transformers come in various sizes, and the larger the transformer, the more powerful it will be. Another thing to consider is the type of current you will be using – AC or DC.

AC is typically used for welding thicker materials, while DC is better suited for welding thinner materials. It’s important to choose a transformer that is rated for the type of current you’ll be using. Additionally, you should consider the duty cycle, which is the amount of time the machine can run before needing to cool down.

Overall, selecting the right transformer is a critical aspect of designing your welding machine, and taking the time to choose the right one will ensure that your machine is efficient and effective.

Selecting the Capacitors and Diodes

When it comes to designing your welding machine, selecting the right capacitors and diodes is essential for optimum performance. Capacitors store and release electrical energy, helping to provide a steady power source for the welder. It’s important to choose capacitors with the appropriate voltage and capacitance ratings, as well as ones with low ESR (Equivalent Series Resistance) for reduced heat dissipation and improved efficiency.

Diodes, on the other hand, are used to control the flow of electrical current in the machine. They act as one-way valves to prevent the reverse flow of current, which can damage sensitive electronic components. When selecting diodes, it’s important to consider their voltage and current ratings, as well as their switching speed and efficiency.

To ensure you choose the right components for your welding machine, it’s important to consult the manufacturer’s specifications and seek the advice of a professional. By selecting the right capacitors and diodes, you can help maximize the performance and longevity of your welding machine, ensuring you get the best results from it for years to come.

Constructing Your Welding Circuit

Designing a welding machine can be a challenging process, and it requires a careful consideration of several factors to ensure that the welding circuit is properly constructed. One of the crucial factors to consider when designing your welding machine is its power source. You need to choose a power source with sufficient voltage and amperage to support your welding needs.

It is also important to select a welding machine with an appropriate duty cycle to ensure that it can handle the frequency and duration of your welding tasks. Another factor to consider is the type of welding process you will be using. Different welding processes require different welding circuits, and it is essential to choose a machine that can handle the specific welding process that you will be using.

Additionally, the electrode holder and the ground clamp you select can affect the integrity of your welding circuit, so it is essential to choose high-quality components. By paying attention to these factors and designing a welding machine that meets your welding needs, you can ensure that your welding circuit is reliable and efficient.

Assembling Your Welding Machine

Want to create your own welding machine at home? You’re in luck because there are plenty of resources available online, including step-by-step guides and even PDFs that can walk you through the process. The first step is to gather all the necessary materials. This will likely include a transformer, diode, and capacitor.

You’ll also need to have basic tools on hand, such as pliers and wire cutters. Once you have everything you need, it’s time to start assembling. This will involve connecting all the components together and wiring them up.

It’s important to follow the instructions carefully so that you don’t damage any of the parts or create a safety hazard. With a little persistence, you should be able to successfully create your own welding machine in no time. So why not give it a try and see what you can create? Who knows, you may discover a new passion for welding and DIY projects.

Wiring Your Welding Machine

Welding Machine Wiring If you’re thinking of assembling your own welding machine, it’s important to know how to properly wire it to prevent safety hazards and ensure optimal performance. First off, it’s crucial to read the manual carefully and identify the power source you’re going to use. Choosing the right cable size and ensuring proper grounding are key factors to ensure your welding machine runs smoothly.

You’ll also need to consider the type of welding you will be doing, as the optimal grounding will differ for MIG, TIG, and stick welding. Additionally, you’ll need to connect the electrodes, which vary depending on the type of welding you’re doing. Always refer to the manual and follow the manufacturer’s instructions.

Proper wiring of your welding machine can mean the difference between a successful weld and a dangerous accident. Remember to always operate your welding machine with safety in mind.

Building the Case

Assembling your welding machine can be a daunting task, but with a bit of patience and attention to detail, it can be done easily. The first step is to gather all the necessary components, including the welding machine itself, cables, electrode holder, and ground clamp. Make sure to read the instruction manual carefully and follow the guidelines provided by the manufacturer.

Once you have all the components, start by locating the input power connection and attaching the power cable. Then, connect the electrode holder and ground clamp to the respective connectors. Ensure that all the connections are tightened securely to avoid any electrical hazards.

After all the components are connected, turn on the welding machine and test it out to make sure everything is working properly. With these simple steps, your welding machine will be ready to use, allowing you to tackle any welding project with ease.

Testing Your Welding Machine

If you want to make a welding machine at home, it’s important to test it properly to ensure it functions correctly and doesn’t pose a safety risk. One way to test your homemade welding machine is to check the output voltage using a multimeter. You can do this by setting the multimeter to the DC Voltage mode and connecting the leads to the positive and negative terminals of the welding machine output.

The reading should match the voltage you set on the welding machine’s control panel. Another test you can perform is to examine the welds you make with the machine to see if they are strong and consistent. You can also test the machine’s ability to weld different materials and thicknesses, and check for any unusual noises or smells during operation.

By testing your welding machine thoroughly, you can ensure that it is safe and reliable for use in your DIY projects. However, if you are unsure about the process of making a welding machine at home, it’s best to consult a professional or refer to a detailed guide or tutorial, such as a “how to make welding machine at home pdf” manual.

Setting Up the Welding Machine

When you decide to start welding, one of the most important steps is to set up your welding machine properly. In order to ensure that your welds will be strong and effective, it’s essential to test your welding machine before you start working. This means checking all of the settings and making sure that everything is properly calibrated.

The first thing you should do is plug in your welding machine and turn it on. Then, you’ll need to make sure that all of the dials and switches are set to the correct settings for your specific welding job. You may also need to adjust the wire feed speed and the heat settings.

Once you have everything set up, it’s time to test your machine by welding a small piece of metal. This will help you determine if your machine is working properly and if you need to make any further adjustments before you start your project. By taking the time to properly test your welding machine, you’ll be able to ensure that your welds are strong, safe, and effective.

Testing the Welding Machine

If you work with a welding machine, it’s important to know how to test it properly to avoid any accidents or issues. To begin testing your welding machine, you first need to make sure it’s properly grounded. Check that the ground cable is tightly connected and that the grounding clamp is securely attached to the workpiece.

Next, test the machine’s voltage output using a voltmeter. You’ll want to set the machine to the desired amperage and then test the voltage at the output terminals. If the voltage is not within the machine’s specifications, you may need to have it repaired or calibrated.

It’s also important to check the electrode holder and cable for any damage or wear. Lastly, before you begin welding, do a test run on some scrap metal to make sure the machine is functioning properly. Remember to always wear appropriate safety gear, like a welding helmet and gloves.

By testing your welding machine regularly, you can ensure it’s working correctly and avoid any unnecessary accidents or damage.

Conclusion

In conclusion, while it may be tempting to dive into the world of DIY welding machines, it’s important to remember that safety should always come first. That being said, with the right knowledge, materials, and tools, making a welding machine at home can be a rewarding and fulfilling experience. Just be sure to do your research, follow proper safety procedures, and don’t be afraid to ask for help along the way.

Who knows, with a little creativity and ingenuity, you could end up with a truly one-of-a-kind welding machine that’s as clever and witty as you are.”

FAQs

What are the materials required to make a welding machine at home?

The materials required to make a welding machine at home include a transformer, diode, capacitor, resistor, and wires.

Is it safe to make a welding machine at home?

Making a welding machine at home can be dangerous if proper precautions are not taken. It is recommended to follow safety guidelines and wear protective gear.

How can I get a welding machine circuit diagram for home use?

You can find welding machine circuit diagram for home use online or in books related to electronics and circuitry.

Can a beginner make a welding machine at home?

Making a welding machine at home requires basic knowledge of electronics and circuitry. If you are a beginner, it is advised to seek help from a professional or take a course in electronics before attempting to make a welding machine at home.

What is the cost of making a welding machine at home?

The cost of making a welding machine at home depends on the specifications and quality of the materials used. On average, it may cost around $50 to $100.

What kind of welding can I do with a homemade welding machine?

With a homemade welding machine, you can perform basic welding tasks like spot welding and tack welding on thin metal sheets. However, it may not be suitable for heavy-duty welding.

Where can I find a step-by-step guide for making a welding machine at home?

You can find step-by-step guides for making a welding machine at home online or in books related to electronics and circuitry. Some websites also provide free downloadable guides in PDF format.