Have you ever considered building your own welding machine instead of purchasing one? With the availability of component parts and the wealth of DIY resources out there, it’s entirely feasible to create a machine that suits your unique needs. In this ultimate guide to DIY welding machines, we’ll explore the ins and outs of building your very own welding machine. From selecting the right components to assembling them correctly, we’ll take you through the steps necessary to create your very own custom welding machine.

Get ready to dive in and explore the world of DIY welding!

Understanding the Basics of Welding Machines

If you’re looking to build a welding machine at home, there are a few things you should know about the basics of welding machines first. Welding machines work by using an electric current to heat up two pieces of metal until they melt and fuse together. The type of welding machine you need will depend on the materials you plan to weld and the thickness of those materials.

Some common types of welding machines include Stick welders, MIG welders, and TIG welders. Once you have the appropriate machine, you’ll need to gather the necessary materials and tools to build your machine at home. These may include copper wire, magnets, a transformer, and a few basic tools like pliers and wire cutters.

While building a welding machine at home may seem like a daunting task, with the right knowledge and tools, it is possible to get it done.

Types of Welding Machines

Welding machines are essential tools in every welding workshop, and understanding their basics is crucial for any welder. There are various types of welding machines available, including MIG welders, TIG welders, Stick welders, and plasma cutters. MIG welders are best for welding thin materials, while TIG welders are ideal for welding exotic metals.

Stick welders are versatile and suitable for all types of welding, and plasma cutters are used for cutting conductive materials. Understanding the specifications and features of each welding machine is crucial to choosing the right tool for the job. For instance, welders should consider the amperage, duty cycle, and voltage of the welding machine.

A welding machine with a high amperage rating can deliver more power for thicker materials, while a high-duty cycle rating indicates the machine can work for long periods. In summary, understanding the basics of welding machines is crucial for any welder, as it allows them to choose the right tool for every welding job.

Components of a Welding Machine

Understanding the basics of welding machines is crucial for anyone looking to get started with welding. Welding machines come in various sizes and types, but they all have a few key components in common. These include a power supply, control panel, electrode holder, and ground clamp.

The power supply is what provides the electricity for welding, and the control panel allows for adjustments to be made to the welding current and voltage. The electrode holder is used to hold the welding electrode, which is the metal rod used to create the weld, and the ground clamp is used to ground the welding circuit. Additionally, some welding machines may have features such as a shielding gas supply or wire feeder.

By understanding these components, you can make an informed decision when selecting a welding machine that will best suit your needs.

How a Welding Machine Works

A welding machine is an essential tool for fusing two or more pieces of metal together. It works by generating heat through an electric arc that melts the metal and cools to form a strong bond. The machine consists of several parts that work together to create the electric arc, which include a power source, electrode holder, ground clamp, and welding cables.

The power source supplies the electricity needed for the arc, while the electrode holder holds the electrode that conducts the electricity. The ground clamp is used to connect the circuit to the metal being welded, ensuring the electricity flows smoothly. Welding cables are responsible for connecting the power source to the electrode holder and ground clamp.

They’re also responsible for regulating the amount of current flowing through the circuit. Overall, a welding machine requires proper handling and operation to ensure safety and the desired results. By understanding the basics of welding machines, you can improve your welding skills and achieve professional results.

Building Your Own Welding Machine

If you’re interested in welding and want to save money, you might consider building your own welding machine at home. Making a welding machine is a project that requires some knowledge of electrical work. The first step is to gather the materials you’ll need, including a transformer, a diode, a capacitor, and some wires.

You’ll have to connect these components in the right order and then attach them to a metal case. Once you’ve built the circuit, you can use it for welding. It’s important to note that building your own welding machine is not for everyone, and it can be dangerous if done improperly.

Therefore, it’s important to do your research and make sure you understand the process before starting. By creating your own welding machine, you’ll have a better understanding of how the machine works, and you’ll be able to make adjustments and repairs if needed. Plus, you’ll have a sense of accomplishment knowing that you built something useful with your own hands.

Gathering Materials and Tools

If you’re interested in building your own welding machine, you’ll first need to gather the necessary materials and tools. The most important component of a welding machine is the power supply, which can range from a simple car battery to a custom-built transformer. You’ll also need a welding gun, which can be purchased or fabricated from scratch, along with a variety of clamps, electrodes, and wires for the welding process itself.

As far as tools go, you’ll need a good set of pliers, wire cutters, and some basic hand tools for assembly. Safety equipment, including gloves, goggles, and a welding helmet, is also essential to protect yourself from the intense heat and light generated during the welding process. By acquiring all of the necessary materials and tools before you begin building, you can ensure that you have everything you need to build a high-quality welding machine that meets your specific needs.

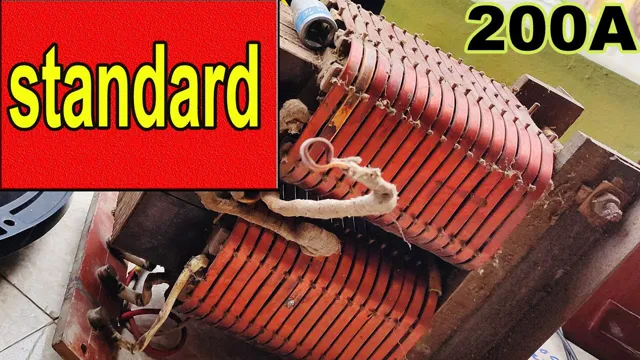

Creating the Transformer

One of the most critical components in building a welding machine is the transformer. Essentially, a transformer takes the voltage from your electrical supply and steps it down to a level that can be used by the machine. Building your own transformer is a complicated process, but with a bit of knowledge and the right materials, it can be done.

First, you’ll need to calculate the specifications for your transformer based on the amperage and voltage requirements of your welding project. Then, you’ll need to source the right materials, including the transformer core, winding wire, and insulating materials. Assembling the transformer is a delicate process that requires attention to detail, but with patience and care, you can create a functional and reliable welding machine.

Whether you’re a hobbyist or a professional welder, building your own transformer can be a rewarding and cost-effective option.

Constructing the Power Supply

If you are building your own welding machine, constructing the power supply is a crucial step. The power supply will provide the necessary voltage and current for the welding process. There are different types of power supplies available, such as AC or DC power supplies, depending on the welding technique you will use.

You can either build your own power supply from scratch or buy a ready-made one. If you choose to build it yourself, you will need to understand the principles of electric circuits and use the appropriate components such as transformers, capacitors, diodes, and resistors. Before starting, it is highly recommended to consult with an experienced electrician or engineer to ensure safety and avoid potential hazards.

Overall, the power supply is the heart of your welding machine, and a well-built one will help you achieve high-quality welds.

Wiring the Components Together

When it comes to building your own welding machine, wiring the components together is a crucial step. You’ll need to first gather all of the necessary components, such as a power source, control circuitry, and a welding transformer. Once you have everything in front of you, it’s time to start connecting the wires.

This process can be complex, so it’s important to take your time and double-check all of your connections as you go. Make sure to use appropriate-sized wires and connectors for each component, and carefully follow any wiring diagrams or instructions that come with your components. It’s also important to keep safety in mind throughout the process, wearing protective gear and ensuring that all power is turned off before beginning any wiring tasks.

With a little patience and attention to detail, you’ll soon have a fully functional welding machine ready to go.

Safety Considerations

When it comes to making a welding machine at home, safety should always be the top priority. Welding can be a dangerous activity if proper precautions aren’t taken. One of the most important safety considerations is wearing protective gear, including a welding helmet, gloves, and proper clothing.

The area should also be well-ventilated to prevent inhaling harmful fumes. It’s also important to have a fire extinguisher on hand in case of any accidents. In terms of the machine itself, it’s important to follow the manufacturer’s instructions carefully and ensure that all components are properly grounded.

Overall, while it is possible to make a welding machine at home, it’s essential to do so in a safe and responsible manner.

Protective Gear

When it comes to any sport or physical activity, protective gear is an absolute must. No matter your level of expertise, safety considerations should always be a top priority. Protective gear may include helmets, pads, mouthguards, gloves, and more depending on the activity you are engaging in.

These items can help prevent serious injuries such as concussion, broken bones, and dental damage. It’s essential to invest in quality protective gear that fits properly and is designed for your specific activity. Remember, accidents can happen, but wearing the appropriate protective gear can help reduce the risk of injury and allow you to enjoy your activity with peace of mind.

Working in a Well-Ventilated Area

When working with any sort of materials or chemicals that could potentially release harmful substances into the air, it’s always important to ensure that you’re working in a well-ventilated area. Proper ventilation can help to minimize your exposure to harmful vapors, dust, and other particles that can cause respiratory issues, headaches, and other health problems. In addition to ensuring that you have a good supply of fresh air circulating in the space, it’s also important to take other safety considerations into account.

This might include using personal protective equipment, like respirators or goggles, to protect yourself from any airborne hazards. By prioritizing safety and maintaining a well-ventilated work area, you can reduce your risk of exposure to harmful materials and ensure a safe and healthy work environment for yourself and your colleagues.

Avoiding Electrical Hazards

Electrical hazards are a common occurrence in homes and workplaces, and the results can be devastating. To avoid being a victim, it is important to take safety precautions and have proper access to electrical resources. When working with electrical equipment, it is essential to keep an eye on the surroundings, ensure that devices are properly grounded and secured, and avoid using damaged equipment.

The use of protective clothing, such as rubber-soled shoes and gloves, can provide a layer of protection against electrical shock. It is always best to have a licensed electrician inspect and maintain electrical systems regularly, as this can help prevent accidents from occurring. With these simple steps, you can significantly reduce the likelihood of electrical hazards in your home or workplace, ensuring the safety of everyone present.

Conclusion

In conclusion, making your own welding machine at home is a daunting task that requires patience, skill, and a willingness to learn. But with the right tools, a bit of creativity, and a lot of determination, you can transform your passion for welding into a tangible project that you can be proud of. So go out there and grab a soldering iron, a transformer, and some wire, and get cracking on your very own homemade welding machine.

Who knows, you might just be the next household name in the world of welding! Just remember to stay safe and use caution when working with electricity, and always wear protective gear to shield yourself from sparks and flying debris. Happy welding, my friends!”

FAQs

What materials do I need to make a welding machine at home?

You will need a transformer, rectifier, capacitors, and other electrical components to make a welding machine at home.

Can I make a welding machine without using a transformer?

No, a transformer is a crucial component in a welding machine. It helps to convert high voltage, low current AC power to low voltage, high current power that can be used for welding.

How can I choose the right transformer for my DIY welding machine?

The transformer you choose should have an output voltage of at least 50 volts and should be capable of delivering at least 50 amps of current.

What type of welding can be done with a DIY welding machine?

A DIY welding machine can be used for stick welding, TIG welding, and MIG welding.

Is it safe to make a welding machine at home?

Making a welding machine at home can be dangerous if you are not experienced in working with electrical components. It is important to follow proper safety precautions and seek guidance from experts if needed.

What is the cost of making a welding machine at home?

The cost of making a welding machine at home can vary depending on the materials you use. It can range from $50 to $500.

Can a DIY welding machine be used for commercial purposes?

It is not recommended to use a DIY welding machine for commercial purposes as it may not meet industry standards and regulations. It is best to invest in a reliable commercial-grade welding machine.