Have you ever seen a segmented bowl and wondered how it’s made? Well, wonder no more! In this article, we’ll take you through the process step-by-step, so you can create your own beautiful segmented bowls. Segmented bowls are unique and fascinating pieces of art that require precision and patience to create. Each bowl is made up of multiple pieces of wood that are glued together, creating an intricate pattern.

The result is a stunning, one-of-a-kind masterpiece that will leave your friends and family in awe. But where to begin? First, you’ll need to choose your wood. There are many options available and the choice will depend on your personal preference and the specific design you have in mind.

Once you have your wood, it’s time to start cutting and gluing the segmented pieces together. This requires precise measurements and careful attention to detail. After gluing, the next step is turning the bowl on a lathe.

This is a process where the bowl is spun on a machine and the wood is shaped with cutting tools. This is where you can really make the design come to life, refining the shape and creating a smooth finish. Lastly, applying a finish will give your bowl that final touch of elegance and protect the wood from damage.

This can be accomplished with a variety of products such as oils, waxes, or polyurethanes. In conclusion, making a segmented bowl is a challenging but rewarding experience that requires creativity, skill, and patience. With some time, effort, and practice, you can create a stunning piece of art that you’ll be proud to display.

So, why not give it a try?

Materials You Will Need

If you’re new to woodworking and want to try your hand at making a segmented bowl, there are a few materials you’ll need. First, you’ll need a variety of different woods in different colors and grains, as well as a table saw, a miter saw, a bandsaw, a drill press, and a lathe. You’ll also need glue, clamps, sandpaper, and finish.

The table saw will help you cut your wood into strips, while the miter saw will let you cut those strips into segments of equal length and angle. The bandsaw will help you cut the rings for your bowl, while the drill press will let you make holes in each segment for dowels and glue. Finally, the lathe will help you shape and turn your bowl.

It may seem like a lot of equipment, but each tool plays an important role in the process of making a segmented bowl.

Wood Glue

Wood glue is one of the go-to adhesives for woodworking projects. It’s a versatile and durable adhesive that can be used in a variety of applications. To use wood glue, you’ll need a few basic materials.

First, you’ll need the wood pieces that you want to glue together. Next, you’ll need sandpaper to smooth any rough edges and create a better bonding surface. You’ll also need a pair of clamps to hold the pieces in place while the glue sets.

Finally, you’ll need the wood glue itself. Choose a high-quality wood glue that is specifically designed for the type of wood you are working with. Using the right materials will help you achieve a strong, long-lasting bond that will hold up to the test of time.

Table Saw

If you’re planning on using a table saw for your next woodworking project, there are a few materials you will need to have on hand before beginning. First and foremost, you will need the table saw itself, as well as a high-quality saw blade appropriate for the type of cutting you will be doing. Additionally, it’s important to have safety equipment, such as safety glasses and ear protection, to protect yourself from any potential hazards.

Other materials you may need include a dust collection system to manage sawdust and debris, as well as clamps and guides to help ensure precision and accuracy in your cuts. By having all of these materials at the ready, you’ll be well-prepared to take on any woodworking project with your table saw.

Miter Saw

When it comes to using a miter saw, having the right materials is essential. First and foremost, you will need a miter saw that is appropriate for the project at hand. This could be a 10-inch or 12-inch saw, depending on the size of the cuts you need to make.

In addition to the actual saw, you will need a sturdy workbench or stand to secure the saw in place during use. You’ll also want to have specialized blades for the saw that are designed for the specific materials you’ll be cutting. This could include wood-specific blades for woodworking projects or metal-specific blades for projects involving metal materials.

Finally, it’s important to have safety equipment, such as eye and ear protection, to ensure that you stay safe while using the saw. By having the right materials on hand, you’ll be well-prepared to tackle your miter saw projects with confidence and accuracy.

Clamps

When it comes to working with clamps, there are a few essential materials that you will need to ensure a successful project. First and foremost, you will need the actual clamps themselves. There are a variety of different types of clamps available, including bar clamps, pipe clamps, C-clamps, and spring clamps.

The type of clamp you choose will depend on the specific job you are working on, so it’s important to choose the right one for the task at hand. Additionally, you’ll need something to protect your work surface from the pressure of the clamp, such as scrap wood or a piece of cloth. Finally, to make sure your clamp is securely fastened, you may want to use a clamp pad to prevent slippage and ensure a tight grip.

With these materials in hand, you’ll be ready to tackle any clamping job with confidence and ease.

Wooden Dowels

Wooden dowels are a versatile material that can be used in a wide variety of DIY projects. If you are planning to use wooden dowels in your project, there are a few materials that you will need to have on hand. First, you will need the dowels themselves, which come in a variety of sizes and lengths.

It is important to choose the right size and length for your project to ensure that it is strong and sturdy. You will also need a saw to cut the dowels to the desired length. A drill will be necessary to create holes in the dowels.

You may also need sandpaper to smooth the edges and surfaces of the dowels. Finally, wood glue will be necessary to attach the dowels to other pieces of wood or to secure joints. With these materials on hand, you will be ready to create all kinds of beautiful and functional projects using wooden dowels.

Preparing Your Wood

If you want to make a segmented bowl, the first step is preparing your wood. To start with, ensure you have a suitable piece of wood, free from any defects, such as knots, cracks or rot. Once you have selected your wood, you can begin the process of preparing it for the segmented bowl.

This process involves cutting your wood into manageable pieces called segments. You should know the number of segments you need for the bowl you want to make. So, you may need to do some calculations beforehand.

Once you have the number of segments figured out, use a saw to cut your wood into equal pieces and then mark them with reference lines to help ensure accuracy. It’s important that the segments are cut precisely, as any inconsistencies can affect the overall structure of your bowl. Once you have all the wood pieces cut, you can start gluing the segments together, which is the next step in making your segmented bowl.

Choose Your Woods Carefully

When it comes to preparing your wood, choosing the right type of wood is crucial. You want to choose a type of wood that will be durable and last for a long time, as well as one that will retain its natural beauty over time. Oak and cedar are excellent choices for outdoor furniture, as they are both very strong, resilient woods that can withstand the elements well.

However, if you are looking for a wood that is more affordable, consider pine or spruce. These woods are more affordable and can look beautiful after proper sanding and staining. No matter which wood you choose, it is important that you take the time to prepare it properly before using it.

This may involve sanding, staining, or sealing the wood, depending on its type and intended use. By preparing your wood properly, you can ensure that it will look great and last for many years to come.

Thickness and Width Recommendations

When preparing your wood for a new project, it’s important to consider the thickness and width of the wood you’re working with. These factors can greatly impact the overall strength and durability of your finished product. Generally, thicker and wider boards will provide more stability and strength than thinner ones, but it’s important to find the right balance based on your specific project needs.

Additionally, it’s important to properly condition and prepare your wood before starting to work with it. This can involve sanding, planing, or even soaking the wood to help prevent warping and cracking. By taking the time to properly prepare your wood, you can ensure a finished product that is both beautiful and sturdy, no matter what project you have in mind.

Cut Your Wood into Strips

If you’re getting ready to start a woodworking project, one of the first things you’ll need to do is prepare your wood. This may include cutting your wood into strips before starting your project. To do this, you’ll need to measure your wood and mark where you want to make your cuts.

Then, using a saw or other cutting tool, carefully cut your wood into the desired strips. It’s important to take your time and make precise cuts, as this will ensure that your wood is uniform and consistent in size. Additionally, be sure to wear appropriate safety gear such as goggles and gloves to protect yourself while cutting your wood.

By taking the time to properly prepare your wood, you’ll set yourself up for a successful woodworking project.

Glue Your Wood Strips Together

Preparing your wood strips for a woodworking project involves gluing them together to create larger and more stable pieces. This process is known as laminating and is commonly used for tabletops, door panels, and other furniture. First, make sure your wood strips are planed to an equal thickness.

Then, apply glue to one edge of each strip and use clamps to press them together. Once the glue has dried, you can remove the clamps and use a planer to level the surface. It’s important to use a high-quality glue that is appropriate for your wood species and intended use.

The resulting laminated wood will be stronger and less prone to warping than individual strips. Don’t skimp on preparation – taking the time to laminate your wood strips correctly will ensure a successful and long-lasting woodworking project.

Creating the Bowl Segments

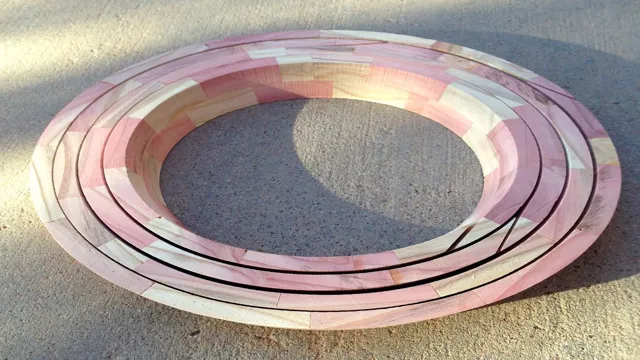

If you’re eager to learn how to make a segmented bowl, you’ll need to start by creating the bowl segments themselves. First, select the wood species you want to use and cut it into small pieces of the same size using a band saw. You can then arrange the pieces into groups to create specific patterns, and glue them together.

To make sure the segments stay together, you might want to use clamps. It’s important to let the glue dry for at least 24 hours before moving on to the next steps. Once the segments are glued and dry, you can use a table saw to make bevel cuts on each segment, which will allow them to fit together perfectly.

Creating bowl segments can be challenging at first, but it’s a crucial step in crafting a beautiful and functional segmented bowl that you can proudly display in your home.

Cut Your Segments Using a Miter Saw

A miter saw is a great tool for cutting segments when creating a wooden bowl. To ensure that your bowl is perfectly symmetrical and well-balanced, it’s important to use a miter saw to make precise cuts. This can be a bit tricky, as each individual segment needs to be an exact angle to fit together seamlessly.

However, with a little practice, you’ll be able to cut your bowl segments with ease. When using a miter saw, it’s important to make sure that your blade is sharp and properly aligned, and that your fence is set to the appropriate angle. You’ll want to be sure to use a high-quality wood blade with a fine tooth count to prevent chipping and splintering.

With these tips in mind, you’ll be well on your way to creating beautiful, symmetrical wooden bowls using a miter saw.

Assemble the Segments Using Dowels

To create a beautiful segmented bowl, it is essential to assemble the segments accurately and securely using dowels. The first step is to prepare the individual segments. Start by selecting the type of wood you want to use and then cutting it into strips that are the same width and thickness.

Next, create a bevel on each strip using a miter saw. The angle of the bevel will depend on the number of segments you want to use. Once all the segments are cut and beveled, the next step is to drill dowel holes into each segment.

It is crucial to accurately mark the positions for the dowel holes so that they line up correctly during assembly. Use a jig to drill the holes for precision and consistency. After drilling the holes, it is time to glue the dowels and segments together.

Apply wood glue to the dowels and insert them into the corresponding holes. Then, press the segments together, making sure they are lined up correctly. Finally, let the glue dry completely before moving on to the next step.

By using dowels and wood glue, you can securely assemble the segmented bowl and ensure that it will last for many years to come.

Glue Together the Segments

Creating a beautiful wooden bowl requires several segments glued together to form a cohesive shape. To start, you’ll need to determine the size and quantity of the bowl segments you’ll need. Once you have your measurements, you can begin cutting and shaping the pieces of wood accordingly.

You’ll then need to apply glue to the edges of each segment and carefully join them together. It’s important to ensure that each segment is aligned correctly and that there are no gaps or inconsistencies. Some tips to keep in mind during this process include using clamps to hold the segments in place as the glue dries, checking each joint for any excess glue that needs to be cleaned up, and allowing the glue to fully dry before continuing on with the process.

With a little patience and attention to detail, you can create a stunning wooden bowl that will last for years to come.

Turning Your Bowl

If you’re interested in making a segmented bowl, turning the bowl is one of the most important steps to ensure it comes out looking great. First, make sure you have a good lathe setup and have carefully aligned the bowl blank, centered it, and locked it in place with the tailstock. Begin by roughing the outside of the bowl, shaping it into the desired form.

Once you’ve achieved the right shape, it’s time to start sanding the outside of the bowl before moving on to the inside. The initial sanding should be done with coarse sandpaper, usually around 80 grit, before gradually transitioning to finer grits as you progress through the sanding process. After the initial sanding, it’s important to clean the bowl, removing any dust or debris that might have accumulated on the surface.

Remember to be patient and take your time with each step, ensuring the bowl turns out exactly how you want it to. By following these steps, you can create a beautiful segmented bowl that you can be proud of.

Mount the Bowl on the Lathe

Mounting the bowl on the lathe is where the real fun begins, as you’ll see your bowl start to take shape for the first time. To start, select the appropriate lathe chuck, based on your bowl’s size and shape. Then, place the blank on the lathe bed and secure it with the tailstock.

Adjust the lathe height and tool rest so that you can work comfortably. Before turning the lathe on, make sure you’ve tightened the chuck securely around the bowl blank. Once the lathe is running, use a roughing gouge or bowl gouge to shape the exterior of the bowl.

Be sure to wear protective gear and keep your tools sharp. Once you’ve turned the exterior to your liking, use a bowl gouge or scraper to shape the inside of the bowl. Remember to take your time and take frequent breaks if needed.

As you approach the final shape of the bowl, switch to sandpaper of increasing grit to smooth out any rough spots and achieve the desired finish. And there you have it, your very own handmade bowl!

Shape Your Bowl

Turning a bowl is one of the most satisfying woodworking processes you can experience. It involves taking a block of raw wood, mounting it on a lathe, and guiding a cutting tool across its surface in a carefully choreographed dance. As you work, the bowl takes shape before your eyes, moving from a rough hunk of timber to a smooth, elegant vessel.

It’s a great way to unleash your creativity, experimenting with different shapes and wood species to craft unique and personalized bowls that reflect your personality. And the best part is that you don’t need a lot of fancy equipment to get started; just a lathe, some carving tools, and a bit of patience! Whether you’re a seasoned woodworker or a beginner, turning a bowl is an accessible and rewarding project that is sure to bring you joy. So why not give it a try and see what possibilities you can unlock?

Sand Your Bowl

When it comes to turning your bowl, sanding is an essential step that you shouldn’t miss. Sanding the bowl helps smooth out any rough bumps left from the turning process, creating a more polished and refined finish. To start, you’ll want to use a range of sandpapers with increasing levels of grit, starting from a coarse grit and working your way up to a fine grit.

This will gradually remove any imperfections and provide a smooth surface for the finish to adhere to. Make sure to sand in the direction of the grain, moving from one end of the bowl to the other, ensuring that you don’t miss any spots. The end result will be a beautiful, polished bowl that’s not only functional but also visually appealing.

So, don’t forget to sand your bowl and enjoy the beauty of your finished creation!

Finish Your Bowl

As woodturners, we often spend a lot of time creating beautiful bowls that can be used in a variety of ways, such as serving food or as a decorative piece. But what many people don’t realize is that the process of turning a bowl isn’t complete until we finish it properly. This is where the phrase “finish your bowl” comes in.

In order to finish your bowl, you need to take the time to sand and seal the wood so that it is food safe, easy to clean, and resistant to water damage. This will not only make your bowl look better, but it will also ensure that it lasts for years to come. So don’t let all your hard work go to waste – make sure you finish your bowl properly!

Conclusion

In conclusion, making a segmented bowl requires patience, precision, and a bit of creativity – just like any great work of art. With the right tools and techniques, you can turn a pile of wooden segments into a stunning and functional masterpiece that will impress anyone who lays eyes on it. So, channel your inner woodworker, let your imagination run wild, and get ready to create something truly amazing.

After all, who says bowls have to be boring? Go forth and craft!”

FAQs

What materials do I need to make a segmented bowl?

To make a segmented bowl, you will need a variety of wood types, a saw, wood glue, clamps, sandpaper, and a lathe.

Can I use any type of wood for a segmented bowl?

Yes, you can use a variety of wood types, including exotic woods, to create a unique and beautiful segmented bowl.

How do I create the segments for the bowl?

To create the segments for the bowl, you will need to use a saw to cut the wood into thin strips and then glue them together in a repeating pattern.

Do I need a lathe to make a segmented bowl?

Yes, a lathe is a necessary tool for making a segmented bowl, as it allows you to shape the bowl and create a smooth finish.

What is the process for turning the bowl on the lathe?

The process for turning the bowl on the lathe involves mounting the blank onto the lathe, using a variety of tools to shape the bowl, and sanding and finishing the bowl to create a smooth surface.

Can a beginner make a segmented bowl?

Yes, a beginner can make a segmented bowl with practice and patience, but it may be helpful to take a woodturning class or get guidance from an experienced woodturner.

How long does it take to make a segmented bowl?

The time it takes to make a segmented bowl will depend on the complexity of the design and the skill level of the woodturner, but it can take anywhere from several hours to several days to complete.