Hey there gearheads! Check out this quick and easy DIY guide on how to make your very own compression tester. With a compression tester, you’ll be able to accurately diagnose engine problems and ensure that your vehicle is running at optimum performance. Whether you’re a seasoned mechanic or a beginner, this guide will provide you with the step-by-step instructions needed to make a compression tester at home.

No need to spend your hard-earned cash on a pre-made compression tester when you can simply create your own with a few basic supplies. In this blog, we’ll explore the tools and materials needed, as well as offer tips and tricks to ensure a successful build. If you’re a novice in the field of automobile maintenance, don’t worry – this guide is designed with you in mind.

We’ll take the confusion out of the process and empower you with the knowledge to tackle this project confidently. So what are you waiting for? Let’s get started on building your very own compression tester and reap the benefits of a smoother-running engine. Trust us; your vehicle will thank you.

Introduction

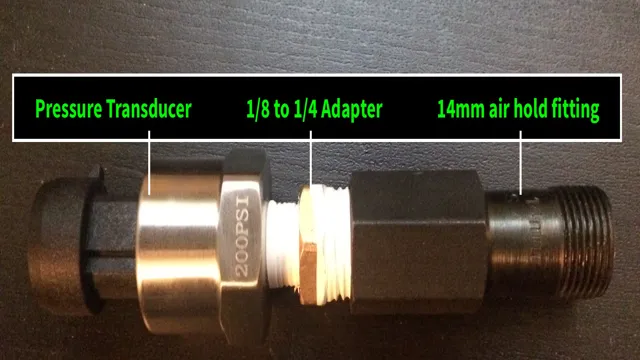

If you’re wondering how to make a compression tester, it’s actually a fairly simple process. The first step is to gather materials, including a pressure gauge, a hose, and a threaded spark plug adapter. Next, remove a spark plug from the engine and screw the adapter in its place.

Then, attach the hose to the adapter and the pressure gauge to the other end of the hose. Finally, turn on the engine and measure the compression as it runs. This is a great way to check the condition of your engine and make sure everything is running smoothly.

With a little bit of time and effort, you can make your own compression tester and save money on expensive mechanic fees. So, if you’re up for a DIY challenge, give it a try!

Explanation of Compression Tester

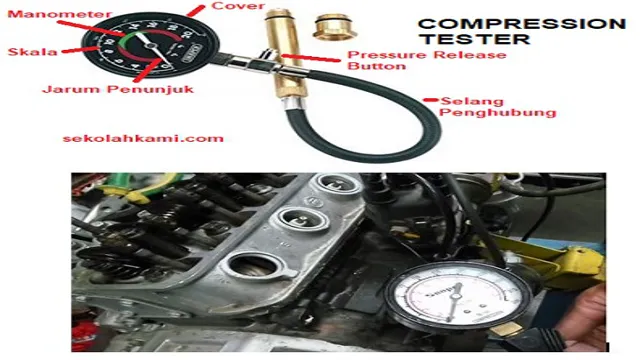

Compression tester is a device that is used to test the compression of an engine in a vehicle. It measures the compression pressure in each cylinder of the engine and helps to determine the engine’s overall health. This device is essential for maintaining the engine and identifying any possible problems that may cause a loss of power or other issues.

The device comes in various types and styles, with some offering additional features such as a built-in pressure gauge or a digital display. One of the essential features of a compression tester is its ability to accurately measure the compression pressure and provide a result that can be compared to the manufacturer’s specifications. This helps to identify any possible issues and determine the best course of action to rectify them.

Overall, a compression tester is an essential tool for any mechanic or vehicle owner who wants to keep their engine running smoothly and efficiently.

Benefits of a Compression Tester

Compression tester If you’re an avid driver or mechanic, you’ve probably heard of a compression tester, but what does it do and how can it benefit you? Well, a compression tester measures the pressure of your engine’s cylinders when they ignite. This measurement can indicate whether your engine is healthy and running efficiently or if there are any issues that need to be addressed. By using a compression tester, you can identify any problems early on and prevent them from turning into costly repairs down the line.

Additionally, a compression tester is a valuable tool if you’re in the market for a used car. By checking the engine’s compression, you can determine whether the car has been well-maintained and whether it’s worth investing in. So, whether you’re a mechanic or a car enthusiast, a compression tester is an indispensable tool that can help you keep your engine running smoothly and efficiently.

Materials and Tools Required

If you’re looking to make a compression tester, there are a few materials and tools that you’ll need. Firstly, you will need a pressure gauge with a range that can measure the peak pressure your engine can produce. You’ll then need a spark plug adapter that will allow you to screw it into the spark plug hole and attach the gauge.

Additionally, you’ll need an air compressor or compressed air source to create the compression pressure. A compression tester kit can be purchased from an auto parts store to make things easier. This kit will include all of the necessary components, including the hose, gauge, and adapter.

Alternatively, you can purchase the individual components separately. Either way, it is important to ensure that the components are compatible with each other and with your engine. Overall, making a compression tester is a relatively simple task that can be done with readily available materials.

List of Required Materials

When it comes to starting a new project, having the right materials and tools is essential. Before you begin any project, it’s important to take the time to make a list of everything you will need. This way, you can make sure you have everything before you get started.

Some of the most basic materials you might need include things like paper, pencils, and erasers. If you are working on a more complex project, however, you may need to invest in things like a drafting board or a set of specialized tools. Some commonly used tools for crafting include scissors, glue, tape, rulers, and cutting mats.

Don’t forget to also think about the materials you will need for completed project, such as paints, fabrics, yarns, and other decorative items. By taking the time to consider all the materials and tools needed for your project, you can save yourself a lot of time and frustration in the long run.

List of Required Tools

If you’re planning to take on a DIY project, it’s essential to have all the necessary tools and materials on hand before you begin. Depending on the project’s scope, you may require a range of different items, but some common tools are essential for almost any job. For instance, a set of screwdrivers, pliers, and wrenches can come in handy for all sorts of repairs around your home.

You’ll also want to have a hammer, a measuring tape, and a level at your disposal. Other useful tools include a power drill, a circular saw, and a jigsaw. When it comes to materials, you’ll need a variety of items such as nails, screws, wood glue, sandpaper, and paint or stain depending on your project.

It’s crucial to have a complete list of required tools and materials before you begin, so you can ensure that the project goes smoothly and avoid any last-minute trips to the hardware store. With all the right tools on hand, you’ll be equipped to take on any DIY job with confidence.

Step-by-Step Guide

Do you want to know how to make a compression tester? It’s actually easier than you might think. First, gather the necessary materials, which include a pressure gauge, a rubber-tipped nozzle, and a hose with threading on both ends. Next, remove the spark plugs from the engine and attach the hose to the spark plug thread.

Connect the other end of the hose to the pressure gauge and start the engine. As it runs, the gauge will measure the pressure inside the cylinder and indicate whether there are any leaks or deficiencies in the engine’s compression. This homemade compression tester is simple to assemble and can save you time and money in diagnosing engine problems.

So why not give it a try?

Step 1: Purchase a Pressure Gauge

If you want to keep a close eye on the tire pressure of your car, purchasing a pressure gauge is the first step towards ensuring that your tires remain in good condition. A pressure gauge is a must-have tool that accurately measures the tire pressure and helps prevent issues such as under-inflation, which can cause unnecessary wear and tear on your tires. Without a pressure gauge, you might not even know when your tire pressure is low, increasing the risk of a flat tire or even a blowout.

By investing in a pressure gauge, you can stay on top of tire maintenance and enjoy a more comfortable and safer ride. It’s a small price to pay compared to the cost of replacing tires prematurely or facing potential accidents. With a pressure gauge, you can quickly measure your tire pressure and make sure it’s within the recommended range.

Whether you’re a seasoned driver or a beginner, a pressure gauge is an essential tool to have in your car, and you won’t regret investing in one.

Step 2: Prepare the Materials

When it comes to preparing the materials for your project, there are a few important things to consider before getting started. First and foremost, make sure you have all the necessary materials on hand, including any tools, equipment, or supplies that you may need. This will save you time and prevent any unnecessary trips to the store.

Additionally, it’s important to read through any instructions or guidelines for the project to ensure that you understand the process and have the materials and tools required. Once you have all your materials in order, take the time to organize them and set up your workspace in a clean and organized manner. Having a designated workspace will help streamline the process and make it easier to focus on the task at hand.

With these steps in mind, you’ll be well on your way to successfully preparing the materials for your project. So, gather your materials, organize your workspace, and let’s get started!

Step 3: Assemble the Compression Tester

To assemble your compression tester, follow these simple steps. First, insert the gauge into the base of the tester and secure it in place using the screws provided. Next, attach the extension hose to the end of the gauge and the spark plug socket adaptor onto the other end of the hose.

This will allow you to connect the tester to your engine’s spark plug. Finally, adjust the pressure release valve and make sure that the gauge reads zero before use. With these steps complete, your compression tester is assembled and ready to use.

Just be sure to follow the manufacturer’s instructions carefully to ensure that you get accurate readings. By using this tool, you’ll be able to diagnose any problems with your engine’s compression and take the necessary steps to get it running smoothly again.

Step 4: Test the Compression

After compressing a file using various compression techniques, it’s important to test the compression to ensure that the file remains intact and usable. This step involves decompressing the file and verifying that it’s still in the correct format. You want to make sure that none of the data has been lost or corrupted during the compression process.

One way to test the compression is by comparing the file size before and after compression. If the compressed file is significantly smaller, this is an indication that the compression was successful. However, you also need to check that the file is still readable and the data is intact.

If you notice any anomalies, it’s important to re-compress the file using a different method or adjusting the parameters until you achieve the desired result. By following these steps, you can ensure that your compressed files remain intact and usable.

Conclusion

In conclusion, making a compression tester is a DIY project that is both practical and rewarding. By following the steps outlined above, you can create your very own device for measuring engine compression with just a few simple materials. Plus, not only will you impress your gearhead friends by bragging about your homemade compression tester, but you’ll also save money and feel a sense of satisfaction from making it yourself.

So go ahead and give it a try – your engine (and your wallet) will thank you!”

Summary of Steps

If you’re looking to take the plunge and start your own business, it can be overwhelming to know where to begin. Fortunately, with a step-by-step guide, the process can feel much more manageable. The first step is to develop a solid business plan that includes market research, financial projections, and a clear mission statement.

Once you have a plan in place, you’ll need to choose a legal structure for your business and register it with the appropriate state and federal agencies. From there, you can secure funding through investors or loans and start building your team. It’s also crucial to establish your brand through a website, social media presence, and other marketing efforts.

As your business grows, it’s important to stay agile and adapt to new challenges and opportunities. With commitment and perseverance, you can turn your entrepreneurial dreams into a successful reality.

Final Thoughts on Making a Compression Tester

Creating a compression tester at home is an excellent way to save some money while ensuring the efficient performance of your engine. With just a few basic tools and materials, you can make your own compression tester quickly. First, determine the type of spark plug threads used in your engine to ensure you get the correct adapter size for the compression tester.

Next, connect the adapter to the valve stem of the engine cylinder and attach the hose of the tester to the adapter. Follow the gauge on the tester to measure the compression pressure of each cylinder. A compression reading higher than 100 PSI indicates optimal engine performance, while anything less may require further investigation.

Finally, ensure that the engine is hot before testing it for accurate results. In conclusion, making a compression tester at home is a simple and affordable way to ensure your vehicle’s engine is running efficiently.

FAQs

What materials do I need to make a compression tester?

To make a compression tester, you will need a pressure gauge, a compression hose, and an adapter that fits your engine’s spark plug hole.

How much does it cost to make a compression tester?

The cost of making a compression tester will vary depending on where you purchase your materials. However, you should be able to make one for under $50.

Can I use a compression tester on any type of engine?

Compression testers come in different sizes and shapes, so you need to purchase one that is designed for your type of engine.

How do I use a compression tester on my car?

To use a compression tester, remove the spark plug and screw in the adapter. Connect the compression hose to the adapter, and then attach the pressure gauge to the other end of the hose.

What is a good compression reading for an engine?

A good compression reading for an engine will vary depending on the make and model, but generally, the compression reading should be between 100-200 PSI.

What does a low compression reading indicate?

A low compression reading is an indication that there is a problem with your engine’s cylinders, pistons, or valves.

How can I determine if my engine has low compression?

To determine if your engine has low compression, you need to use a compression tester to measure the PSI of each cylinder.