Joining two 2×12 boards together can seem intimidating for those who may not have experience with woodworking or construction. However, with the right tools and guidance, it can be a manageable task. In this step-by-step guide, we’ll explain the process of joining two 2×12 boards together, and provide helpful tips to make the process easier.

Whether you’re building a deck, a large shelving unit, or any similar structure requiring longer boards, joining two 2×12 boards together can save you time and money. It creates a stronger joint and eliminates the need for buying longer, more expensive lumber. This guide will cover the different types of joinery techniques available, the tools needed to complete the job, and safety precautions that should be taken.

By the end, you’ll have a clear understanding of how to join your 2×12 boards together and create a strong, durable joint. So, let’s get started!

Materials You Will Need

So you need to join two 2×12 together and you’re not quite sure where to start. Well, don’t worry because it’s actually a pretty straightforward process. The materials you will need for this project include a circular saw, wood glue, clamps, screws, and a drill.

First, measure and cut your two 2×12 boards to the desired length. Apply wood glue to the edges of the two boards, then press them firmly together. Use clamps to hold the boards together as the glue dries.

After the glue has dried, drill pilot holes and secure the two boards together with screws. Be sure to countersink the screws so that they are flush with the surface of the boards. And there you have it, two 2×12’s joined together and ready to use for your next project!

2 2×12 boards

If you’re planning on building a structure that requires solid support, you’ll need to have 2 2×12 boards on hand. These are incredibly strong and durable pieces of lumber that can be used for a variety of construction projects. They’re made from high-quality wood and are pressure-treated to prevent rot and decay, ensuring they’ll last for years to come.

When building with 2 2×12 boards, there are a few things to keep in mind. First, you’ll need to make sure that they’re properly joined together to create a solid foundation. This can be accomplished using bolts, screws, or other hardware designed for this purpose.

You’ll also need to ensure that the boards are level and evenly spaced, to avoid any structural issues down the line. With proper care and attention to detail, 2 2×12 boards can be an essential part of any construction project.

4-inch screws

If you’re planning to tackle a DIY project that requires screws, it’s important to have the right materials on hand. For projects that require a bit of strength and durability, 4-inch screws are a great option. These screws are often used for outdoor projects like building decks or fences, where they need to be sturdy enough to withstand the elements.

But they can also be used indoors for tasks like attaching heavy shelves or constructing furniture. When shopping for 4-inch screws, make sure to choose ones that are made from high-quality materials like stainless steel or coated to resist rust and corrosion. With the right materials in hand, you can be confident that your project will be strong and secure for years to come.

Circular saw

Circular saw When it comes to using a circular saw, having the right materials is crucial to getting the job done right. Firstly, you’ll need a circular saw blade that is compatible with your saw. Make sure to choose the appropriate blade for the material you will be cutting, whether it be wood, metal, or masonry.

Other necessary materials include safety equipment such as gloves, eye protection, and ear protection, as using a circular saw can be loud and potentially dangerous. Additionally, having a sturdy work surface is important to ensure the safety and accuracy of your cuts. A sawhorse or workbench can provide the necessary stability.

Finally, having a proper measuring tool, such as a tape measure or square, can aid in making precise cuts and help to avoid any mistakes. With the right materials on hand, you can confidently tackle any circular saw project with ease.

Measuring tape

The measuring tape is a simple but essential tool that every DIY enthusiast, carpenter, or tailor should have in their arsenal. To use a measuring tape effectively, you will need a few materials besides the tool itself. Firstly, you will need a flat surface to measure against, such as a workbench or the floor.

Secondly, it’s recommended to have a pencil or marker on hand to make notes of your measurements so you don’t forget them. Additionally, it’s often helpful to have a square or right angle tool to ensure your measurements are accurate and precise. Using a measuring tape is not complicated, but having these materials on hand will make it easier and more efficient.

So, before you dive into your next DIY project or take on a tailoring task, make sure you have these materials ready to go!

Pencil

When it comes to using pencils, there are a few materials you will need to get started. First and foremost, you will need a pencil. But not just any pencil will do – you’ll want to choose one that suits your needs.

Are you looking for a pencil for drawing, writing, or shading? Different types of pencils are better for different tasks. Additionally, you may want to invest in a good pencil sharpener to keep your pencil tips sharp. Erasers are also a must-have – even the best artists make mistakes! Finally, you may want to use a smudging tool, such as a blending stump, to create smooth shading effects.

With these materials in hand, you’ll be ready to start creating amazing works of art or simply jotting down your thoughts and ideas with ease.

Drill

If you want to take on some heavy-duty home improvement projects, a drill is a must-have tool in your arsenal. It’s a versatile power tool that can drill through a variety of surfaces such as wood, metal, or concrete. There are corded and cordless options that you can choose from depending on your needs.

Corded drills are more powerful and have unlimited run time, but the cords can get in the way. On the other hand, cordless drills are more portable and allow for greater flexibility, but their battery run time is limited. In addition to a drill, you’ll also need drill bits to help you drill through various materials.

These can be purchased separately in different shapes and sizes, depending on your project requirements. Make sure to also have a pair of safety goggles on hand to protect your eyes from flying debris. By ensuring you have the necessary materials, you’ll be able to take on any DIY project with ease.

Step-by-Step Instructions

If you’ve ever needed to join two 2×12 together, there are a few steps you can follow to make sure the connection is strong and secure. First, make sure the two boards are straight and smooth. It’s best to work with boards that are the same length so they are easy to align.

Next, apply wood glue to both surfaces that will be touching. Use a brush to spread the glue evenly over the entire surface. Then, press the two boards together firmly and use clamps to hold them in place while the glue dries.

It’s important to let the glue dry completely before removing the clamps to ensure a strong bond. Finally, reinforce the joint with screws. Drill pilot holes through one board and into the other and then insert screws.

Repeat this process every 6-8 inches along the length of the joint to ensure the two boards are securely joined together. With these steps, you can create a strong and stable joint between two 2×12 boards.

1. Measure and mark the boards

When you’re working on a DIY project that involves cutting wood, one of the first steps you’ll need to take is measuring and marking the boards. This process is crucial to ensuring that your project turns out the way you want it to. To start, you’ll want to gather all of the boards you’ll be using for your project.

Then, using a tape measure, take precise measurements of the boards you’ll be cutting. Once you have your measurements, use a straight edge and a pencil to mark where you’ll be making your cuts. This will help you ensure that you’re making accurate cuts and that your final product will fit together correctly.

It’s important to take your time and be as precise as possible during this step, as even a small mistake can lead to big problems down the line. By taking the time to measure and mark your boards correctly, you’ll be setting yourself up for success and ensuring that your project turns out just the way you want it to.

2. Cut the boards to length

Cutting the boards to the required length is an essential step in any woodworking project. However, it might appear overwhelming if you’re new to the craft. Begin by taking precise measurements of the boards required for your project.

It’s advisable to double-check the measurements before you start cutting to avoid making costly mistakes. Once you have the dimensions, mark the board’s length using a pencil and a ruler. You could also use a square to ensure that your markings are straight and square.

While cutting, ensure that you hold the wood firmly and cut along the line, taking care not to veer off course. Whether you’re using a handsaw, circular saw, or a table saw, always remember to prioritize safety and keep your fingers clear from the cutting area. With a steady hand and patience, you’ll be able to expertly cut the boards to size and start assembling your project.

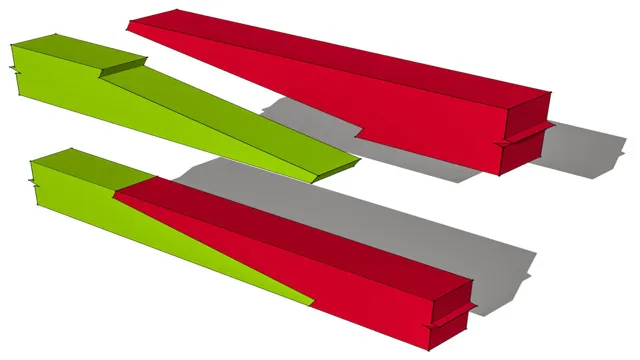

3. Make a V-groove on each board

After you have chosen the perfect wood for your DIY project, it’s time to make a V-groove on each board. This step may seem intimidating, but with a few tools and some patience, you’ll be able to create a professional-looking detail that will add character to your finished product. First, you’ll need a router with a V-groove bit.

Set the bit to the desired depth and clamp the board securely to your work surface. Start at one end of the board and plunge the router into the wood, moving it smoothly along the length of the board until you get to the other end. Repeat this step for each board.

Make sure to take your time and be cautious of the router bit, as it can be dangerous if not handled properly. When you’re finished, you’ll have a clean, precise V-groove that will enhance the rustic look of your wooden project. Keep in mind that this step will add some time to your project, but it’s worth it for the end result.

4. Apply wood glue to the V-groove

When it comes to woodworking, one of the most important steps is applying wood glue to the V-groove. This step ensures that the joint will be strong and durable. To begin, you’ll want to make sure that the V-groove is clean and free of any debris.

Next, apply a thin layer of wood glue to the inside of the groove. Make sure to spread the glue evenly and avoid using too much. Once the glue is applied, you can then fit the two pieces of wood together and clamp them tightly.

Allow the glue to dry completely before removing the clamps. The use of a quality wood glue is essential for a strong and long-lasting joint. Follow these steps to ensure a successful woodworking project!

5. Join the boards together and clamp them

Now that you’ve got your boards cut and sanded to perfection, it’s time to bring them together! To begin, lay your boards side by side, and make sure they’re all facing the same direction. If you’re using a joining method like biscuits or dowels, go ahead and make your marks for where the holes will go. Next, apply a generous amount of glue to one edge of a board, and press it firmly against the next board.

Repeat this process for all of your boards until they’re all stuck together. When you’re happy with the placement of your boards, use clamps to keep them in place while the glue dries. Depending on the type of wood you’re using, you may need to leave your boards clamped for a few hours or even overnight.

Once the glue has set, you can remove the clamps and check that everything is securely attached. Now that your boards are joined together, it’s time to start working on the finishing touches. If you’re planning to add any decorative elements like inlays or carvings, now is the time to do so.

Or, if you’re happy with the simplicity of your boards, you can move on to sanding and applying a finish. Whatever your next steps may be, you can rest assured that your joined boards will provide a sturdy and attractive base for your woodworking project.

6. Drill countersink holes

When it comes to woodworking, one crucial step is drilling countersink holes. Countersink holes are cone-shaped depressions made in wood to allow the screw head to sit flush with the surface. This not only looks better but also prevents the screw head from sticking out and potentially causing harm or damage.

Here’s a step-by-step guide on how to drill countersink holes: Firstly, select the right drill bit size and countersink drill bit for your screw size. Next, attach the countersink bit to your drill and adjust the depth setting to ensure you drill the right depth. Place the tip of the bit on the surface of the wood and start drilling.

Apply even pressure and make sure the drill bit stays perpendicular to the surface. Drill to the desired depth and make sure the hole is clean and free of debris. Repeat the process for each hole you need to countersink.

In conclusion, drilling countersink holes is an important step in ensuring the durability and aesthetic appeal of a woodworking project. Following this step-by-step guide will help you properly drill countersink holes and achieve a professional finish. Remember to double-check your measurements and use the right tools for the job.

With a little practice and patience, you’ll become a pro at drilling countersink holes.

7. Screw the boards together with 4-inch screws

If you’re building a structure using boards, it’s crucial to securely fasten them together. That’s where 4-inch screws come in handy. Once you’ve aligned the boards according to your desired design, drill pilot holes to ensure that the screws go in smoothly.

Next, use an electric screwdriver to drive the screws through the boards, securing them together. Make sure to space the screws evenly and use the appropriate number of screws for the length of the boards. By screwing the boards together, you’ll create a strong and stable structure that can withstand the test of time.

So go ahead and give it a try – you’ll be amazed at the results!

Tips and Tricks

Joining two 2×12 boards together can be a tricky process, but with the right tips and tricks, it can be done easily. One effective method is to use wood glue and screws to secure the boards together. First, apply a generous amount of wood glue to the edge of one board and then press it firmly against the other board.

Next, drill pilot holes at an angle and then screw the boards together with wood screws. Another option is to use a biscuit joiner to create slots in the edges of the boards, insert a biscuit, and then glue the boards together. Whichever method you choose, ensure that the boards are straight and aligned properly before joining them.

Happy woodworking!

Use a straight edge to ensure a straight cut

When it comes to cutting any type of material, a straight edge is a lifesaver. By using a straight edge, you can ensure that your cuts are precise and uniform, which is vital for any project. From cardboard to fabric to wood, a straight edge will help you make sure that your cuts are as straight as an arrow.

In addition, by using a straight edge, you can prevent unnecessary wastage of material due to incorrect cutting. So the next time you need to make a cut, grab a straight edge and get started. Your project will turn out as neat as a pin and you’ll save yourself a lot of time and frustration in the process.

So, always remember to keep a straight edge handy when working on your projects!

Make sure the V-groove is deep enough for the glue to adhere properly

When it comes to installing V-groove flooring, it’s crucial to ensure that the groove is deep enough for the glue to adhere properly. This is particularly important if you’re opting for the glue-down installation method instead of the click-lock method. One useful tip to keep in mind is to test the depth of the groove using a small piece of the same flooring material.

If the piece fits snugly and the groove is deep enough for the glue to take hold, you’re good to go! Additionally, it’s crucial to clean and level the subfloor before laying down the flooring, as any debris or unevenness can prevent the adhesive from bonding adequately. With these tips in mind, you can ensure that your V-groove flooring installation goes smoothly and lasts for years to come.

Apply pressure evenly when clamping the boards together

When it comes to woodworking projects, there’s one crucial step to ensuring a strong and sturdy finished product: applying pressure evenly when clamping the boards together. This may seem like an obvious tip, but it’s one that is often overlooked or improperly executed. Uneven pressure can lead to gaps between the boards or even bowing, compromising the integrity of the piece.

To avoid this, make sure you have enough clamps to evenly distribute the pressure along the length and width of the boards. Tighten each clamp a little at a time, moving back and forth between them, to ensure that the pressure is applied evenly. Another helpful tip is to use cauls, or flat pieces of wood, between the clamps and the boards to distribute pressure and prevent damage to the wood.

By taking the time to apply pressure evenly and using the right tools, you’ll ensure a strong and durable finished product.

Pre-drill countersink holes to avoid splitting the wood

Pre-drilling countersink holes is a smart move when you’re working with wood. Not only does it prevent the wood from splitting, but it also ensures that the screws are flush with the surface of the wood. It’s an easy process that involves drilling a small hole at the precise spot where you want to insert a screw, and then widening the top of the hole to create a countersink.

The countersink allows the screw head to rest flush with the wood, creating a smooth surface that is free from any sharp edges. If you don’t pre-drill countersink holes, the wood may crack or split as you drive the screws in, which can ruin your project. So, take the time to pre-drill countersink holes, and you’ll be rewarded with a stronger, more professional-looking outcome.

Conclusion

Joining two 2×12’s together is a bit like creating a perfect meal. First, you want to select the right ingredients, making sure your boards are straight, strong, and a perfect match for each other. Then, you’ll want to prepare your boards, taking care to sand away any rough spots and ensure a flush fit.

Finally, you’ll need to cook up a solution that will keep your boards together for the long haul. Whether it’s a sturdy screw or a trusty bolt, the key is to find the right recipe that will give you a seamless and strong joint. With the right preparation and technique, joining two 2×12’s can be a piece of cake (or lumber, as it were)!”

By following these simple steps and using the right materials, you can easily join two 2×12 boards together to create the perfect length for your project.

If you’re looking to join two 2×12 boards together for your project, there are a few tips and tricks to keep in mind to ensure a strong and sturdy connection. One important factor is choosing the right materials, such as high-quality wood glue and strong screws or bolts. Additionally, it’s important to prepare the boards properly by making sure they are clean, dry, and free of any defects or irregularities.

When it comes time to join the boards, using clamps or other tools can help ensure a tight and secure fit. By taking these steps and using the right techniques, you can create a seamless and durable connection between your 2×12 boards and achieve the perfect length for your project. So, what are you waiting for? Get started on your next woodworking project today!

FAQs

What is the best method for joining two 2×12 boards together?

The best method for joining two 2×12 boards together is by using a scarf joint. This involves cutting a diagonal line across the board’s width to create a tapered edge that will fit tightly against the corresponding edge of the second board. Glue and clamps can then be used to hold the two boards together.

Can I use screws to join two 2×12 boards together?

While screws can be used to join two 2×12 boards together, they may not be the most reliable method of connection. Screws alone may not provide enough strength and stability to hold the boards together over time. It’s recommended to use a combination of glue and screws or dowels for added strength.

What size screws should I use to join two 2×12 boards together?

The size of screws needed to join two 2×12 boards together will vary depending on the length of the boards and the thickness of the material. As a general rule, use screws that are at least 1.5 times the thickness of the material being attached. In this case, you would need screws that are at least 3 inches long.

Can I use a biscuit joiner to join two 2×12 boards together?

Yes, a biscuit joiner can be used to join two 2×12 boards together. Biscuits are small, oval-shaped wooden pieces that are inserted into matching slots in the boards being joined. The biscuits help to align and strengthen the joint. However, it’s best to also use glue and clamps with this method.

Is it necessary to sand the edges of the 2×12 boards before joining them together?

Yes, it is recommended to sand the edges of the 2×12 boards before joining them together. This will help to ensure a tight fit between the two boards and create a stronger joint. Sanding can be done by hand or with a power sander. Be sure to remove any rough or splintered areas for a smooth and even surface.