Are you struggling with joining end grain to end grain? It can be a tricky process, but fear not! The solution is here. In this how-to guide, we will take you through a step-by-step process to join end grain to end grain. End-grain to end-grain joinery is one of the strongest woodworking joints, but it’s more complex than it looks.

With a few techniques and some practice, you can quickly master this essential skill. The secret to a strong joint lies in the preparation and technique, and we’re here to help you with both. From choosing the right glue to the best clamping techniques, we’ll cover everything you need to know about joining end grain to end grain.

We’ll go over the common mistakes often made while joining end grain tu for a stronger, more efficient method. Ready to get started? Let’s dive right in!

Understanding End Grain Joinery

End grain joinery is a technique used to connect two pieces of wood with their end grain facing each other. This type of joinery is commonly used in woodworking as it delivers a strong, durable, and aesthetically pleasing bond. However, joining end grain to end grain can be tricky because of the unique structure of the end grain.

Unlike long-grain wood, end-grain wood fibers are porous and absorbent, which means that they require extra attention when it comes to adhesives and fasteners. To ensure a strong bond between two end-grain pieces, it’s essential to choose the right adhesive, such as epoxy or cyanoacrylate glue. Additionally, using dowels or biscuits can add extra support to the joint.

Overall, end grain joinery is a valuable technique for creating long-lasting and beautiful woodworking projects, as long as it’s done correctly.

Explaining End Grain and Its Characteristics

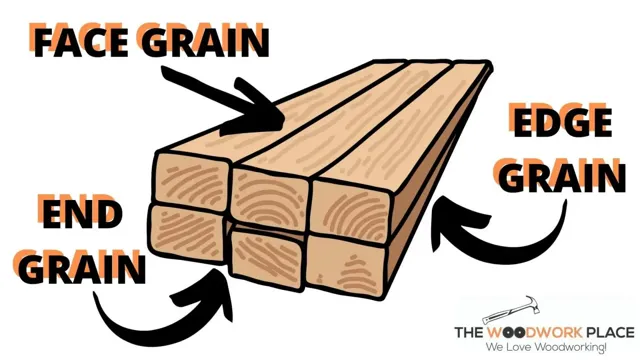

End grain joinery is a woodworking technique that involves joining the end of one piece of wood to the side of another at a 90-degree angle. This type of joinery creates a bond that is stronger than traditional wood joints because it maximizes the wood fibers’ surface area. When wood is cut, the end grain shows the growth rings and feels rough to the touch because the fibers are exposed.

End grain wood is known for its ability to absorb moisture, making it ideal for cutting boards and butcher blocks. It also has a unique aesthetic that showcases the wood’s natural beauty. However, end grain joinery requires more time and effort to create than other types of joinery.

Woodworkers need to sand down the end grain to create a smooth surface and use specialized glue to ensure a strong bond. Overall, end grain joinery is a challenging technique that produces beautiful and durable results.

Benefits of End Grain Joinery

End grain joinery refers to a specialized woodworking technique that involves using the cut ends of wood to create strong and durable joints. Unlike traditional grain joinery, which utilizes the side grain of wood, end grain joinery is often considered to be more robust and long-lasting due to its unique structural properties. End grain joints are able to resist twisting and warping due to their perpendicular orientation, and they also provide a large surface area for glue to adhere to, resulting in a bond that is stronger than the wood itself.

End grain joinery is commonly used in high-load applications, such as in the construction of furniture, flooring, and even musical instruments. Overall, the benefits of end grain joinery include increased strength, longer lifespan, and a more aesthetically pleasing finished product.

Types of End Grain Joints

If you’re wondering how to join end grain to end grain, there are a few common types of end grain joints to consider. The first is the butt joint, which simply involves joining the exposed ends of two boards together. This type of joint works well for simple projects, but isn’t the strongest option.

Another option is the finger joint, which involves creating interlocking fingers on the ends of two boards to join them together. This type of joint is much stronger and is commonly used in furniture and cabinetry. The third option is the mortise and tenon joint, which involves creating a rectangular hole (the mortise) in one board and a corresponding protrusion (the tenon) on the other board to fit into the mortise.

This type of joint is the strongest of the three and is commonly used in high-stress projects like chairs and tables. When choosing which joint to use, consider the strength and aesthetic you’re going for.

Butt Joint

When it comes to end grain joints, one popular method that people use is the butt joint. This type of joint is created by joining two pieces of wood that have square ends together. The joint is then reinforced using screws, nails, or dowels to ensure maximum strength.

One advantage of using the butt joint is that it is relatively simple to create and doesn’t require complex woodworking skills to achieve. However, one downside is that the joint itself is not inherently strong and can be prone to coming apart over time. Therefore, it’s important to use additional reinforcement or glue to ensure that the joint is secure.

Overall, the butt joint is a useful option for creating simple woodworking projects, but it’s important to keep its limitations in mind when using it.

Dovetail Joint

One of the most popular types of end grain joints is the dovetail joint. This joint is commonly used in woodworking because of its strength and durability. The joint is created by fitting a series of interlocking pins and tails together.

The pins on one piece of wood fit into the tails on another, creating a strong and secure connection. The dovetail joint is often used in furniture making and cabinetry, as it can withstand a lot of weight and pressure. When properly constructed, the joint is also aesthetically pleasing.

It adds a touch of craftsmanship and elegance to any piece of furniture. So, if you’re looking to create a sturdy and good-looking joint, the dovetail joint might be a perfect choice.

Mortise and Tenon Joint

When it comes to joining pieces of wood, there are various techniques to choose from. One popular method is the mortise and tenon joint, which involves cutting a cavity (mortise) into one piece of wood and shaping a corresponding protrusion (tenon) on the other, before fitting the two pieces together. This joint provides a strong and enduring connection, perfect for furniture-making or building structures that require strength and stability.

While there are other types of end grain joints, such as dowel joints or box joints, mortise and tenon joints are widely favored for their durability and ease of use, provided you have the right tools and a bit of practice. Whether you’re a professional woodworker or a hobbyist, mastering the mortise and tenon joint is sure to elevate your woodworking skills and enable you to create beautiful, long-lasting pieces of furniture or structures that stand the test of time.

Finger Joint

Finger Joint Finger joint, also known as a comb joint, is one of the most popular types of end grain joints. This joint is formed by cutting alternating fingers into two pieces of wood and fitting them together like puzzle pieces. The interlocking fingers provide a significant amount of surface area for glue, making it a very strong joint.

This type of joint is often used in cabinetry, flooring, and furniture making. The appearance of the joint can vary depending on the size of the fingers and the angle of the cut. The tight fit of the fingers also creates an aesthetically pleasing pattern that can add visual interest to your project.

If you’re looking for a robust and visually striking end grain joint, consider the finger joint.

Steps to Join End Grain to End Grain

If you’re wondering how to join end grain to end grain, there are several steps to follow to ensure a strong and sturdy bond. First, make sure the ends are cleanly cut and free of any splinters or rough areas. Apply glue to both ends, spreading it evenly with a brush or roller.

Press the ends together firmly, making sure they are flush with each other. You can use clamps to hold the joint in place while the glue dries overnight. Once the glue has set, you can reinforce the joint by drilling holes and inserting wooden dowels or screws.

This will add additional strength to the joint and ensure it holds up over time. With these steps, you’ll be able to join end grain to end grain with confidence and create durable woodwork for any project.

Preparing the Wood

When preparing wood to join end grain to end grain, there are a few essential steps to follow to ensure a strong and successful joint. First, it’s crucial to ensure that the end grain is square and flat. One way to do this is by using a table saw to create straight and perpendicular cuts.

The next step is to apply glue to both surfaces and spread it evenly with a brush or roller. Then, press the two pieces of wood together firmly and use clamps to hold them in place while the glue sets. Lastly, allow the glue to dry completely before removing the clamps.

It’s essential to take your time and ensure that every step is done correctly to avoid any weak joints in the future. With these steps, your end grain to end grain joint should be strong and durable, ready for any project.

Measuring and Cutting the Wood

When it comes to joining end grain to end grain, there are a few steps you need to follow to ensure a strong and sturdy joint. First, measure and mark the wood where you want to make the cut. This will ensure that you make precise cuts that fit together perfectly.

Next, use a saw to make the cuts. Be sure to hold the wood securely in place to prevent it from moving and creating uneven cuts. Once you have made the cuts, you need to glue the two pieces of wood together.

Apply a generous amount of glue to both pieces, making sure to spread it evenly. Finally, clamp the two pieces of wood together and let them dry completely. This will create a strong bond that will keep the two pieces of wood together for years to come.

By following these steps, you can create a sturdy joint that will stand the test of time.

Dry Fitting the Joint

Dry fitting the joint is an essential step when it comes to joining end grain to end grain. This process involves temporarily fitting the pieces together without the use of glue, allowing you to make any necessary adjustments before permanently gluing them. To start, ensure that the end grains fit together precisely, as any gaps or misalignments can weaken the joint.

You can then use a marking gauge to outline the joint, making it easier to align the pieces during assembly. Afterward, test fit the joint by sliding the pieces together to ensure a snug and flush fit. If everything looks good, you can proceed with gluing the joint.

However, if there are any discrepancies, make the necessary adjustments before moving forward with the gluing process. Remember, a well-fitted joint is crucial for a sturdy and robust project that will withstand the test of time.

Gluing and Clamping the Joint

Gluing and clamping the joint is the next step when joining end grain to end grain. This process is crucial in ensuring the strength and durability of the joint. Before gluing the joint, it is essential to ensure that the surfaces are flat and even.

The glue is then applied to both surfaces using a brush or a roller, making sure to cover every part of the joint. Next, the pieces are firmly pressed together and clamped using a clamp or a vise. The clamping pressure should be sufficient to ensure that the pieces do not move or slip during the drying process.

After the glue has dried, the excess glue is removed using a scraper or sandpaper. The joint is now ready for finishing. Always remember that the success of the glue joint depends largely on the quality of the glue and the clamping pressure applied.

Conclusion and Final Thoughts

In conclusion, joining end grain to end grain may seem like a daunting task, but with the right technique and tools, it can be a piece of cake. Remember to align your boards precisely, use a strong adhesive and clamps, and take the time to sand and finish your project to ensure a flawless end result. With these tips, you’ll be able to join end grain with ease and impress your friends with your woodworking skills.

“

FAQs

What is end grain and why is it difficult to join together?

End grain refers to the cut ends of wood fibers that are porous and absorbent, making them difficult to bond together. Joining end grain to end grain requires a specific technique and adhesive.

What are some techniques for joining end grain to end grain?

Some techniques for joining end grain to end grain include using dowels, biscuits, splines, or a joint called a finger joint. Each technique has its own unique advantages and disadvantages.

What type of adhesive should be used for joining end grain to end grain?

A strong, waterproof adhesive that has good penetration into the porous end grain is recommended, such as a polyurethane glue or a two-part epoxy.

Can a pocket hole jig be used for joining end grain to end grain?

A pocket hole jig is not recommended for joining end grain to end grain as it doesn’t provide enough strength for this type of joint.

Is it recommended to clamp the joint when joining end grain to end grain?

Yes, clamping the joint is essential to ensure a tight bond between the end grain surfaces. It’s recommended to use multiple clamps to evenly distribute pressure across the joint.

Can end grain be sanded before joining it to another piece of end grain?

Yes, sanding end grain surfaces can help to provide a better bonding surface for the adhesive, but care should be taken to not oversand and remove too much material.

What types of wood are best suited for end grain to end grain joints?

Hardwoods, such as maple, oak, and ash, are generally better suited for end grain to end grain joints due to their density and strength. Softer woods, such as pine, may require additional reinforcement or a different type of joint.