Joining end grain to end grain can be a tricky task, but with the right tips and techniques, you can ensure a strong and sturdy joint. End grain joints are known for their strength, making them a popular choice for woodworking projects that need to support a lot of weight. However, they can also be difficult to work with because the end grain is porous and does not glue well.

In this blog post, we’ll take a look at some tips and techniques to help you successfully join end grain to end grain and create a strong and durable wood joint that will last for years to come. So, whether you’re a beginner or an experienced woodworker, read on to learn how to join those troublesome end grains with confidence and ease.

Introduction: Understanding End Grain

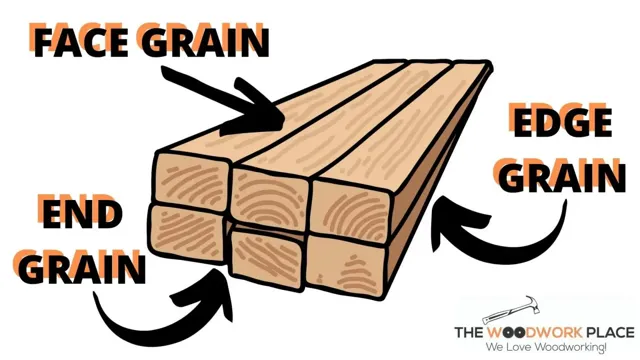

If you’re new to woodworking, understanding end grain is essential to recognizing how to join end grain to end grain properly. End grain is the exposed surface of wood that is cut perpendicular to the direction of the grain. Unlike long-grain wood, which is much stronger and more stable, end grain is unstable, brittle, and porous.

As a result, joining two pieces of end grain together can be challenging and requires a specialized technique. To prevent weak joints, woodworkers use various methods to strengthen the end grain, such as adding glue, using joinery techniques such as dovetail or mortise and tenon, or reinforcing them with dowels and biscuits. By understanding the characteristics of end grain and its limitations, you’ll ensure that your woodworking projects remain sturdy and long-lasting.

What is End Grain?

End-grain is a term used to describe wood that has been cut perpendicular to its growth rings, resulting in a pattern that is different from the long-grain cut commonly seen in furniture. Understanding end-grain is important because it plays a significant role in the strength and durability of wood products, especially when it comes to woodworking. End grain boards are often used in butcher blocks and other kitchen cutting surfaces because the hard fibers of the wood stand up well to sharp blades, preventing damage to the board and the knife.

End-grain construction also provides a unique look to wood products, with intricate patterns and color variations that can highlight the natural beauty of the wood. Overall, end-grain is a distinctive feature of woodworking that lends both beauty and utility to furniture and other wood products.

Why is Joining End Grain Difficult?

End grain is the surface of wood that is perpendicular to the direction of the wood grain, and it is commonly used to create cutting boards and butcher blocks because it is durable and can withstand heavy use. However, joining end grain to other pieces of wood can be difficult because of its structure. End grain is made up of small pores that can quickly absorb any adhesive, causing the bond to be weak.

Additionally, end grain has a tendency to split and crack, making it challenging to create a strong joint. To overcome these challenges, woodworkers often use specialized techniques, such as creating long, angled cuts that fit together like a puzzle or using metal dowels to reinforce traditional joinery. Overall, joining end grain requires a deep understanding of wood properties and patience, but the result is a strong, beautiful piece of woodwork that can last for generations.

Options for Joining End Grain to End Grain

When it comes to woodworking, joining end grain to end grain can be a bit tricky. However, there are several options available to make the process a little bit easier. One popular option is using dowels to join the pieces together.

This involves drilling holes in the end grain of both pieces and then inserting dowels into the holes to connect them. Another option is using biscuit joinery, which involves cutting slots called “biscuit slots” into the end grain of the wood and then inserting an oval-shaped biscuit into the slot before joining the pieces together. A third option is using a technique called “finger jointing”, which involves cutting small notches (or “fingers”) in the end grain of the wood and interlocking them with the corresponding notches on the other piece.

Regardless of which technique you choose, each one has its own benefits and drawbacks. With the right tools and a bit of practice, however, joining end grain to end grain can be a breeze.

Butt Joint

When it comes to joining end grain to end grain, a butt joint can be a viable option. A butt joint is where the end grain of one piece meets the end grain of another without any additional material or joinery connecting them. While not the strongest joint, a butt joint can be useful for certain woodworking projects.

One advantage of a butt joint is its simplicity. Since no additional materials or joinery are required, it can be an easy and quick way to join two pieces of end grain. However, it is important to note that the joint may not be very strong and could potentially break or come apart under significant stress.

To strengthen a butt joint, there are a few options. One is to apply glue to the end grains before joining them together. This can help to reinforce the joint and create a stronger bond between the two pieces.

Another option is to add dowels, biscuits, or other joinery to the joint to provide additional support. It is also important to consider the type of wood being used. Some woods are stronger than others and may be better suited for a butt joint.

Additionally, the thickness and width of the wood being joined can have an impact on the strength of the joint. Overall, a butt joint can be a viable option for joining end grain to end grain, but it is important to carefully consider the project and the materials being used to determine if it is the best choice.

Miter Joint

A miter joint is one of the most popular options for joining end grain to end grain. It’s a method of joining two pieces of wood at a 45-degree angle to form a perfect corner. This is a great way of creating a clean, seamless look on your project’s corners.

The strength of the joint depends on how precisely the cuts are made. The closer the joint’s fit, the better its strength. A miter joint can be reinforced with glue and nails, but it’s always important to clamp the joint before fastening it together.

The most significant advantage of using a miter joint is its outstanding visual appeal. However, it can be a challenge to achieve an excellent fit, especially for beginners. One way to improve the fit when making a miter joint is to use a shooting board to plane the cut edges, ensuring that both pieces fit snugly.

Overall, a miter joint is an excellent option for joining end-grain to end-grain and one of my favorites when working on creating a seamless, professional look for my projects.

Biscuit Joint

If you’re looking for a reliable way to join end grain to end grain, biscuit jointing is definitely worth considering. This technique involves cutting a slot into both pieces of wood and inserting a thin, oval-shaped wooden biscuit into the slots. The biscuit is coated with glue and expands inside the slot, creating a strong, tight joint.

Biscuit joinery is a popular choice for everything from tabletops to cabinet frames and provides a durable, attractive joint that’s easy to create with the right tools. With the help of a biscuit joiner and a few basic woodworking skills, you can achieve a clean, precise fit that will stand the test of time.

Techniques for Joining End Grain to End Grain

Joining end grain to end grain can be challenging, but there are several techniques that can be used. One popular method is the use of dovetail joints, which are characterized by their interlocking shape and strong mechanical bond. Another technique is the use of mortise and tenon joints, which involve inserting a tenon (a square or rectangular piece of wood) into a corresponding hole (mortise) in the other piece of wood.

Biscuit joints, dowel joints, and splines are other options that can be used for joining end grain to end grain. It is important to choose the right technique for each project, taking into account factors such as the strength required, the appearance, and the personal preference of the woodworker. Whatever technique is used, it is essential to take care when cutting and fitting the joint, ensuring that the pieces are precisely aligned and snugly fitted together to create a strong, lasting bond.

Clamping Techniques

Clamping Techniques When it comes to joining end grain to end grain, there are a few clamping techniques you can use to ensure a strong and secure bond. One technique is the use of parallel clamps, which allow you to apply even pressure across the entire surface of the joint. Another technique is the use of pipe clamps, which can be adjusted to fit various sizes of wood and provide a strong, secure grip.

You can also use a band clamp, which wraps around the joint and can be tightened with a ratcheting mechanism. Additionally, a bar clamp can be useful for clamping a joint at a right angle. No matter which technique you choose, it’s important to make sure the joint is properly aligned and the glue has enough time to dry before removing the clamp.

With these clamping techniques, you can join end grain to end grain with confidence and create strong, long-lasting woodworking projects.

Wood Glues for End Grain

When it comes to joining end grain to end grain, woodworkers need to choose the right type of wood glue. End grain is known for its porous and rough surface, making it difficult for glue to penetrate deeply and create a strong bond. Fortunately, there are several wood glues designed specifically for this type of application.

PVA (polyvinyl acetate) glue is a popular choice for end grain due to its affordability and ease of use. It creates a strong bond and dries clear, making it ideal for furniture and other decorative items. Another option is epoxy glue, which is known for its superior strength and long-lasting bond.

However, epoxy can be more challenging to use and requires precise mixing ratios to achieve optimum results. Ultimately, the type of wood glue used will depend on the project at hand and personal preference, but it’s essential to choose a glue that is designed to penetrate the end grain for a strong and durable bond.

Using Reinforcements

When it comes to joining end grain to end grain, reinforcements can be incredibly useful. One technique that many woodworkers employ is using dowels or biscuits. Essentially, these are small pieces of wood that fit into drilled holes.

When the two end grain pieces are pressed together, the dowels or biscuits provide extra stability, helping to keep the joint intact. Another option is to use splines, which are thin strips of wood that are inserted into grooves cut into the end grain. Similarly to dowels and biscuits, splines provide extra support to the joint, making it more secure.

By using these techniques, woodworkers can create strong, durable joints that will stand the test of time.

Conclusion: Best Practices for Joining End Grain to End Grain

In conclusion, joining end grain to end grain can be a tricky task, but with a bit of patience and creativity, it’s not impossible. Whether you choose to use traditional woodworking techniques, innovative joinery methods, or even adhesives, the key is to ensure a strong bond that will stand the test of time. So go ahead, take on the challenge of end-to-end joining and prove that even the grainiest of surfaces can find a happy ending!”

FAQs

What are some techniques for joining end grain to end grain?

Some techniques include using dowels, biscuits, or mortise and tenon joints.

Can you use glue to join end grain to end grain?

Yes, but it may not be as strong as other methods and may require additional support.

Is it possible to join end grain to end grain without any fasteners?

Yes, one option is to use a technique called “end grain to end grain locking” where the two pieces interlock like puzzle pieces.

How important is it to have a tight fit when joining end grain to end grain?

It is crucial to have a tight fit in order to ensure a strong joint. Any gaps or inconsistencies may weaken the joint.

Can you join different types of wood end grain to end grain?

Yes, but it is important to consider the different wood densities and characteristics when selecting a joining method.

What is the best saw blade for cutting end grain?

A blade with a high tooth count and a negative hook angle is best for cutting end grain cleanly and with minimal tearout.

How should you prepare the wood surfaces before joining end grain to end grain?

It is important to have flat, smooth, and clean surfaces for the best joint. Sanding or planing may be necessary.