If you own a dust collection system, you know just how much of a hassle it can be to keep it running smoothly. Not only do you have to ensure that the system is properly maintained and cleaned, but you also have to make sure that it’s grounded. Grounding your dust collection system is a crucial step that many people overlook, but it’s incredibly important for both your safety and the longevity of your equipment.

This blog post will provide you with everything that you need to know about how to ground your dust collection system properly, so you can work safely and effectively without any worry.

Understanding Static Electricity

If you have a dust collection system in your work area, it is crucial to understand static electricity and how to ground your system. When dust particles pass through the dust collection system, they can build a static charge that could potentially ignite and start a fire or explosion. To prevent this, you need to ensure that your system is properly grounded.

This means that you need to connect the metal ductwork and any machinery to a ground wire or rod outside the building. Additionally, it is important to use conductive hoses and fittings to prevent static build-up within the system. By properly grounding your dust collection system, you can help avoid potential hazards from static electricity.

So, before you start using your system, take the necessary steps to ensure that it is properly grounded to keep you and your work area safe.

Potential Hazards and Risks

Static electricity can pose a significant hazard in many scenarios, from fueling a car to operating industrial machinery. Understanding static electricity and its potential risks is crucial in avoiding accidents and minimizing damage. When we rub two objects against each other, we create an electrical charge imbalance, leading to static electricity.

This charge can build up and discharge as a spark, which can be dangerous in various situations. For example, in a fueling station, static electricity can ignite gasoline vapors and cause a fire. In an industrial setting, a static spark can ignite flammable chemicals or dust, leading to an explosion.

By recognizing how static electricity works and taking appropriate precautions to prevent its buildup, we can minimize these hazards and keep ourselves and our surroundings safe.

Common Causes of Static Electricity

Static electricity is a common phenomenon that we experience almost every day, particularly during winter months. It occurs when there is an imbalance in the electric charge between two surfaces. One of the main causes of static electricity is friction.

When two different materials rub against each other, the electrons are transferred from one material to the other, leading to a build-up of electric charge. Another cause is separation, where two objects with opposite charges are separated, leading to an electrical discharge. The type of materials used can also affect static electricity.

Objects made of insulating materials, such as plastic or rubber, have a higher likelihood of generating static charge, as opposed to conductive materials like metals. Additionally, the environment plays a significant role, where low humidity levels will amplify static electricity, while high humidity will reduce it. Understanding the causes of static electricity can help us take precautions to prevent it and safeguard ourselves from electrical shocks.

Effective Grounding Techniques

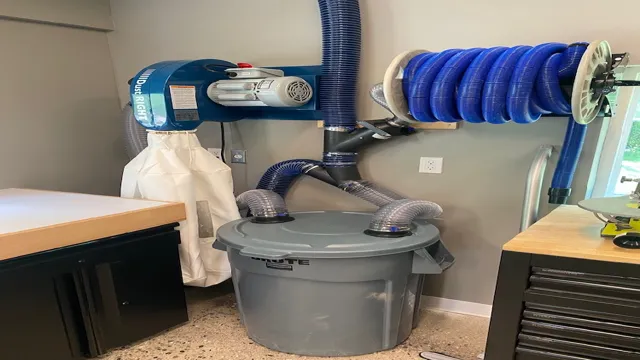

If you’re working with woodworking machines or similar equipment that generates a lot of sawdust and debris, it’s essential to have an effective dust collection system in place. However, even the most powerful system won’t be effective if it’s not properly grounded. Proper grounding is key to ensuring that your dust collection system is safe and effective.

One way to ground your system is to use a grounding wire to connect the metal housing of the collection drum or bag to a ground source, such as a metal pipe or the grounding terminal in your electrical panel. This will help to prevent static buildup, which can be a fire hazard. Another effective grounding technique is to use anti-static hoses, which are designed to prevent static buildup and discharge.

By using these techniques, you can ensure that your dust collection system is safe, effective, and reliable.

Using Conductive Materials

Effective Grounding Techniques with Conductive Materials Grounding is an essential safety measure in electrical systems that involves connecting conductive objects to the earth. It helps to prevent electric shock, fire hazards, and equipment damage that can occur due to electrical faults. One of the most effective techniques for grounding is using conductive materials that provide a path for the electrical current to flow from the faulty equipment to the earth.

These materials are often made of copper or aluminum because they have a low resistance to electrical current. Grounding electrodes, wires, rods, and plates made of these materials are commonly used in residential, commercial, and industrial settings to create a safe electrical environment. A well-designed grounding system using conductive materials can also improve the power quality, reduce interference, and protect against lightning strikes.

When designing electrical systems, it’s important to ensure that the grounding materials and techniques meet the required standards and regulations. Improper grounding can cause serious harm, so it’s always best to seek professional advice if you are unsure.

Proper Grounding for Metal Ductwork

When it comes to metal ductwork, proper grounding is critical for ensuring electrical safety. Effective grounding techniques involve connecting metal ductwork to an earth ground, which reduces the risk of electrical shock and protects electrical equipment. There are various grounding methods available, such as using grounding clamps or straps to connect the ductwork to a grounding conductor.

It is also crucial to consider the location and type of grounding system in use, as well as any applicable codes and regulations. When in doubt, consult with a professional electrician to ensure your metal ductwork is properly grounded. Remember, safety always comes first!

Grounding for Non-Metallic Ductwork

Grounding for non-metallic ductwork is an important consideration for ensuring electrical safety in buildings. Non-metallic ductwork can be made of materials such as plastic, fiberglass, or composite materials that are not conductive. However, it is crucial to ensure proper grounding to reduce the risk of electrical shock or fire.

An effective technique for grounding non-metallic ductwork is to use ground wires or straps. These wires or straps should be connected to the grounding busbar or grounding electrode system. Another technique is to use grounding bushings, which can be installed on the ends of the ductwork to provide a connection to the grounding conductor.

It is important to follow electrical codes and standards when designing and installing grounding systems for non-metallic ductwork to ensure proper grounding and electrical safety. Always seek the advice of a licensed electrician if you are unsure about how to properly ground your non-metallic ductwork.

Tools and Equipment

If you’re working with a dust collection system, it’s important to ensure that it’s properly grounded. This is because dust collection systems can generate static electricity, which can potentially cause sparks and fires. To ground your dust collection system, you’ll need a few tools and equipment.

First, you’ll need a grounding rod that’s long enough to reach the ground outside of your workspace. You’ll also need a wire that’s long enough to connect the grounding rod to the dust collection system. Once you have your tools ready, you’ll need to drive the grounding rod into the ground outside your workshop and attach the wire to the rod.

Next, you’ll need to run the wire to the dust collection system, making sure to connect it to a metal component. This will ensure that any static electricity generated by the dust collection system will be transferred to the ground and prevent potential sparks and fires. Grounding your dust collection system is an important safety measure that should not be overlooked.

Conductive Tape and Wire

Conductive tape and wire are crucial tools for anyone involved in the world of electronics. Essentially, conductive tape and wire are used to create electrical connections and pathways between different components of a circuit. Conductive tape is a type of adhesive tape that has a conductive material integrated into it, while conductive wire is simply wire that is able to conduct electricity.

These tools come in a variety of different types, sizes and materials, making them ideal for a wide range of applications, from connecting simple circuits to creating intricate electronic designs. Whether you’re a hobbyist, an engineer, or a student, conductive tape and wire can help you take your electronic creations to the next level. So, the next time you’re working on an electronic project, don’t forget to make use of these essential tools!

Grounding Clamps and Bolts

Grounding clamps and bolts are essential tools for ensuring reliable and safe electrical connections. These tools provide a secure grounding connection by attaching the grounding conductor to the grounding electrode. The clamp is made of sturdy material and is designed to fit tightly around the grounding wire.

The grounding bolt is also an important tool that helps to establish a solid and reliable electrical connection. It is typically made of copper or another conductive metal and is used to secure the grounding wire to the grounding electrode. These tools come in various sizes and shapes to fit different types of electrical equipment and wiring configurations.

Using grounding clamps and bolts is crucial in preventing electrical hazards such as electric shock, electrical fires, and damage to electrical equipment. They provide a safe path for electric current to flow to the ground, preventing any build-up of voltage that could cause damage or harm. When using these tools, it’s essential to ensure that they are tightened securely to prevent any loose connections.

Loose connections can lead to overheating, which could result in a fire hazard. It’s also important to inspect the tools regularly and replace them as needed to ensure that they remain effective. In conclusion, grounding clamps and bolts play a critical role in maintaining electrical safety and preventing electrical hazards.

Proper use and maintenance of these tools can prevent damage to electrical equipment and injuries to people. By using these tools properly, electrical professionals can ensure that they provide a safe and reliable electrical system for their clients.

Conclusion

In conclusion, grounding your dust collection system is as essential as a base for a house. Without it, the entire structure may crumble. Grounding ensures that the system operates smoothly and efficiently, reducing the risk of fire and explosion.

So, think of grounding as the solid foundation that keeps your workshop safe and secure. Don’t be shocked by the importance of grounding – it’s electrifying!”

FAQs

What is a dust collection system?

A dust collection system is a set of equipment used to filter and collect dust and other fine particles from the air in an industrial or commercial setting.

Why is it important to ground a dust collection system?

It is important to ground a dust collection system to prevent the buildup of static electricity that can lead to fires or explosions in the system.

What are some common methods for grounding a dust collection system?

Common methods for grounding a dust collection system include bonding the system to earth ground, using grounding wires, or using grounding straps.

What size grounding wire should be used for a dust collection system?

The size of the grounding wire used for a dust collection system will depend on the size of the system and the local electrical code requirements. It is best to consult with a qualified electrician or the manufacturer of the system for guidance on proper wire sizing.

How often should a dust collection system be checked for proper grounding?

A dust collection system should be checked for proper grounding on a regular basis, such as during routine maintenance checks or after any modifications to the system.

What are some signs that a dust collection system may not be properly grounded?

Signs that a dust collection system may not be properly grounded include static electricity buildup, sparks, or shocks when operating the system.

Can a dust collection system be retrofitted for proper grounding if it was not initially installed with grounding in mind?

Yes, a dust collection system can be retrofitted for proper grounding by installing grounding wires or straps and bonding the system to earth ground. It is important to consult with a qualified electrician or the manufacturer of the system for guidance on proper retrofitting procedures.