Have you ever purchased a beautiful piece of wood for a DIY project, only to find out that it’s bowed and won’t lay flat? Don’t worry, you’re not alone! Bowing is a common issue with wood boards, especially when they have been stored improperly. It can be frustrating, but fortunately, it’s not impossible to fix. By following some simple steps, you can easily flatten a bowed board and salvage your project.

In this article, we’re going to show you how to straighten out your board, and get it back to a usable state. So, grab your tools and let’s get started!

What Causes a Board to Bow

If you work with wooden boards, you’ve probably encountered the frustrating problem of a warped or bowed board. A bowed board is when a board appears to curve in the middle. This is usually caused by uneven moisture content from the wood drying out.

When one side of the board loses moisture quicker than the other, it causes the board to bow. Other factors that can cause a board to bow include the way it was sawn, the type of wood, and how it was stored. However, there are some ways to fix a bowed board.

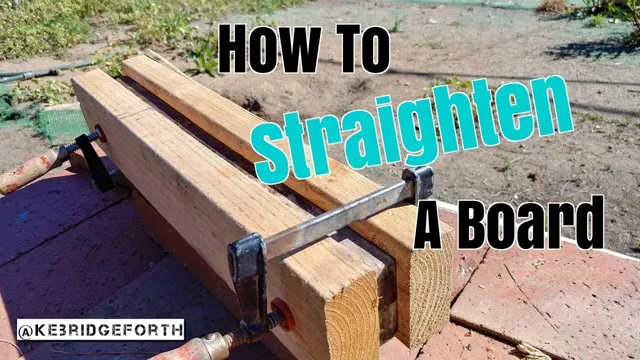

Firstly, you can try steaming the board using a steam box or steam iron to introduce moisture evenly to the board. Another way is by clamping the board flat, either by hand or using weights to hold it down until it flattens. Lastly, some people may choose to use a planer or sander to remove the bow by reducing the thickness of the affected area.

By knowing what causes a bowed board, you can take the necessary steps to fix the problem and ensure your woodworking projects are of the highest quality.

Moisture Content

Moisture content. Have you ever wondered what causes a board to bow? Well, the answer lies in the moisture content of the wood. Wood is a natural material that can absorb and release moisture depending on its environment.

When a board absorbs moisture, it expands, and when it loses moisture, it contracts. This process of expansion and contraction can cause a board to bow, warp, or twist. If a board dries too quickly or unevenly, one side will lose moisture faster than the other, causing it to bow.

Conversely, if a board is exposed to too much moisture, it will absorb too much, causing it to bend. The key to avoiding bowing is to ensure that the moisture content is consistent throughout the entire board. This can be achieved by properly storing and acclimating the wood before use.

Remember, a little bit of bowing is normal and can be corrected with the proper techniques, but excessive bowing may require replacing the board altogether.

Improper Storage

When it comes to woodworking, few things are more frustrating than a board that has bowed. There are a few reasons why this might happen, but one of the most common is improper storage. If wood is not stored correctly, it can be exposed to too much moisture or too little, and this can cause it to warp.

Additionally, if wood is stored in a cramped or uneven space, it can become compressed on one side, which can lead to warping over time. To ensure that your boards stay straight, make sure that they are stored in a dry, climate-controlled area where they can lay flat and have plenty of room. By taking the time to properly store your wood, you can avoid the frustration of dealing with bowing boards down the line.

Preparation

If you’ve ever worked with wood, you know that sometimes boards can become bowed over time. This can be frustrating, especially if you’re working on a project that requires a straight board. However, there are ways to flatten a bowed board.

Before you begin, it’s important to prepare the board by removing any screws or nails that might be in it. Next, you’ll want to mark the high spots on the board so that you know where to apply pressure. One method for flattening the board is to clamp it to a work surface, using shims to apply pressure to the high spots.

Another method is to use a hand plane or jointer to shave off the high points until the board is straight. Whichever method you choose, be sure to take your time and work carefully to avoid damaging the board. With a little patience and some know-how, you can easily flatten a bowed board and get back to your woodworking project in no time.

Assess the Board

When it comes to assessing a board, preparation is key. It’s important to have a clear understanding of the board’s purpose, goals, and responsibilities before beginning the assessment process. This includes reviewing the board’s bylaws, meeting minutes, and other relevant documents.

It can also be helpful to research best practices for board governance and to gather feedback from board members, stakeholders, and external experts. By taking the time to prepare thoroughly, you’ll be better equipped to ask meaningful questions and make informed recommendations that can help the board improve its performance and achieve its goals. So, if you want to analyze a board and offer valuable insights, make sure you start by doing your homework.

This will ensure that your assessment is thorough, insightful, and actionable.

Determine the Bow Direction

Before firing your bow, it is important to determine the direction in which you will shoot. This will ensure that you do not harm anyone and keep yourself from getting injured. To prepare for this, you need to understand that your bow will only shoot in one direction – the direction you are facing.

So, before you draw your bowstring, make sure that you are facing your intended target. When practicing, try to choose an obstacle-free area and keep in mind that winds can affect the direction of your arrow. By paying attention to these factors, you can determine the bow direction and make sure that you hit your target safely and accurately.

Remove Any Loose Splinters or Debris

When it comes to preparing a surface for painting or staining, the first step is to remove any loose splinters or debris. This is an important step as it ensures that the surface is not only clean but also smooth. You don’t want to paint or stain over any splinters or debris as it will make the final result look unprofessional.

To remove any loose splinters or debris, you can use a scraper or sandpaper. If the surface is heavily damaged, you may need to use a saw or other tools to clean it up. Remember to wear protective gear like gloves and goggles to prevent injuries.

By taking the time to prepare the surface properly, you’ll ensure that your paint or stain adheres better, and the end result will be a beautiful, long-lasting finish.

Flattening Techniques

Flattening a bowed board can be a daunting task for anyone who is not familiar with woodworking. However, there are several techniques that can be used, depending on the severity of the bow. One simple method involves using wet paper towels or rags on the concave side of the board and applying heat with an iron.

As the towels dry, they will expand and generate pressure on the board, which can help to flatten it. Another technique involves using a jointer or planer, which will require more skill and equipment. The first step is to identify the bowed section and mark it up with chalk.

Then, slowly run it through the planer or jointer, removing thin layers of wood until the board becomes flat. It’s essential to be cautious when using these tools to avoid removing too much wood, which can result in a warped board. With a little bit of patience and practice, anyone can learn how to flatten a bowed board and achieve professional woodworking results.

Using a Planer

When it comes to flattening wood, there are a variety of techniques you can use to achieve a smooth surface. One of the most common methods is using a planer. A planer is a woodworking tool that removes thin layers of wood from a board, resulting in a level, flush surface.

To ensure the best results, it’s important to prep your wood before running it through the planer. Make sure your board is free of any debris, and double-check for any nails or screws that might damage the planer’s blades. Additionally, it’s essential to have the planer set up correctly.

Take the time to properly adjust the cutter head, infeed, and outfeed tables to achieve the desired thickness and prevent snipe. By following these tips and techniques, you can achieve a flat, even surface on your wood projects using a planer.

Using a Jointer

A jointer is an essential tool when it comes to woodworking and can be used for various purposes. One of the most common tasks is flattening and smoothing rough lumber. There are various techniques for flattening wood using a jointer, including face jointing, edge jointing, and combination jointing.

Face jointing involves running the timber over the jointer’s cutter head to flatten one face, creating a reference surface. The timber is then flipped, and the other side is flattened to create a parallel surface. Edge jointing is used to create straight edges on a board, ensuring that they are perpendicular to each other.

Combination jointing involves both face and edge jointing, allowing you to create a flat board with straight edges. In any case, it is essential to follow safety guidelines while working with a jointer to avoid injuries. Ensure that you wear appropriate safety gear and keep your hands, hair, and clothing away from the cutter head.

With proper technique and equipment, you can create beautiful, flat, and smooth wood pieces with a jointer.

Using Hand Tools

When it comes to woodworking, flattening a surface is an essential part of the process. Using hand tools like hand planes, card scrapers, and sandpaper can help achieve a flat and smooth surface. One popular technique for flattening is called “scrubbing.

” This technique involves using a hand plane with a curved blade to quickly remove material from the surface. Once the rough spots are removed, a jack plane can be used to begin leveling the surface. The goal is to remove high spots while leaving low spots untouched.

Repeating the process with a smoothing plane will create a smooth and flat surface. Card scrapers can also be used to smooth out any remaining imperfections. Ultimately, using hand tools for flattening may take more time and effort, but the end result is a more personalized and satisfying woodworking experience.

Final Steps

If you’re dealing with a bowed board, don’t worry – it’s a common problem that can be easily fixed with the right steps. To begin, make sure the board is completely dry before you begin working on it. Then, create a surface for the board to rest on, with the bowed side facing up.

Now, take a straightedge and measure the amount of bow in the board. Once you have this measurement, you can use a hand plane or jointer to remove the high spots and create a flat surface. Make sure to work slowly and take small amounts off the board at a time until it’s completely flat.

Finally, sand the board with fine-grit sandpaper to remove any rough spots and achieve a smooth finish. By following these steps, you can flatten a bowed board quickly and easily, and have it back to its original form in no time!

Sand the Board

Now that you’ve finished staining your board, it’s time to sand it down to a smooth finish. Choose a sandpaper with a grit of 220 or higher and use long strokes in the direction of the grain. Make sure to sand evenly, focusing on any rough spots or raised grain.

It’s important to use a light touch when sanding to avoid removing too much of the stain or damaging the wood. If you plan on applying multiple coats of stain or a protective finish, be sure to lightly sand in between coats to ensure a smooth surface. Once you’ve finished sanding, wipe the board down with a clean, damp cloth to remove any dust or debris.

Your board is now ready to be used and admired for years to come.

Apply Finishing Coat

After applying the base coat and letting it dry, it’s time to move on to the final steps of applying the finishing coat. This last layer will give your surface a smooth and polished look. Before starting, make sure your surface is completely clean and free from any debris.

This will ensure that the finish will adhere properly and stay in place for a long time. When choosing the finish, consider the purpose of the surface you are painting. If it will be exposed to moisture or heavy traffic, use a more durable finish.

If you want a shiny surface, choose a gloss finish. For a subtle sheen, go for a matte or satin finish. When applying the finishing coat, use a high-quality brush or roller to ensure an even layer.

Make sure to keep a wet edge and avoid going over the same spot more than once to prevent uneven buildup. Once you are done, let it dry completely before using the surface. With the right technique and care, your surface will look as good as new!

Store Properly

Now that you’ve invested time and money into purchasing high-quality coffee beans, it’s essential to store them properly to maintain their freshness and flavor. One of the best ways to store coffee beans is in an airtight container away from light, heat, and moisture. This helps preserve the aromatic oils and prevent oxidation, which can cause coffee to lose its flavor and become stale.

It’s best to store the coffee beans in a cool, dry place, such as a pantry or cabinet, and keep them away from the sun or any heat sources. If possible, avoid storing them in the refrigerator or freezer because the moisture can cause the beans to absorb unwanted odors and flavors. By following these simple storage tips, you can ensure that your coffee beans stay fresh and flavorful for longer, providing you with a delicious cup of coffee every morning.

Conclusion

In conclusion, straightening out a bowed board may seem daunting, but with a bit of effort and patience, it can be done. Remember to start by identifying the bow, using moisture and weight to coax the board back into shape, and properly storing the board after it has been flattened. So don’t let a stubborn bend get in the way of your woodworking dreams – give that bow the boot and get back to crafting with a board that’s as flat as can be!”

FAQs

What causes a board to bow and become uneven?

Boards may bow due to moisture imbalance, improper drying, or uneven pressure on the wood.

Can a bowed board be fixed?

Yes, a bowed board can be fixed by flattening it through a series of steps that involve planing, sanding, or using a jointer to remove the curved sections.

What tools are needed to flatten a bowed board?

Tools needed to flatten a bowed board include a jointer, planer, sandpaper, woodworking clamps, and a straight edge.

How do I prevent a board from bowing in the future?

To prevent a board from bowing in the future, ensure proper moisture balance, store wood correctly, and avoid exposing it to extreme temperatures or humidity.

Can I flatten a bowed board without power tools?

Yes, it is possible to flatten a bowed board without power tools by using hand planes, scrapers, or sandpaper.

What safety measures should be taken when working with bowed boards?

Safety measures when working with bowed boards include wearing protective gear, keeping fingers away from blades, and securing the wood properly to avoid movement during the flattening process.

How long does it take to flatten a bowed board?

The time it takes to flatten a bowed board depends on the severity of the bow and the tools used. It can take anywhere from a few minutes to several hours to complete the process.