Are you interested in welding machines? Do you know how to calculate the power consumption of a welding machine? The power consumption of a welding machine is a crucial factor to consider when using it, as it ensures that you have enough electricity flowing to the machine to produce the best results. In this blog, we’ll cover the basics of how to calculate the power consumption of a welding machine, including why it’s essential and some of the things you need to consider when doing so. By the end of this post, you’ll be an expert in welding machine power consumption and can use this information to improve your welding experience.

So, let’s get started!

Understanding the Basics of Power Consumption

When it comes to understanding the power consumption of a welding machine, it’s important to know that the amount of power it uses varies depending on several factors. One of the most fundamental ways to calculate power consumption is by measuring the amperage and voltage used by the welding machine. You can do this by using a simple formula: Power (watts) = voltage (volts) x current (amps).

However, keep in mind that different types of welding machines require different amounts of power. For example, a TIG welding machine typically consumes less power than a MIG welding machine because its voltage output is lower. Additionally, factors like the material being welded, the level of energy required and the types of electrodes used can all impact the overall power consumption of the welding machine.

By understanding these basic principles, you can calculate the power consumption of your welding machine and make informed choices about your energy usage.

How Is Electrical Power Measured?

Electrical power is the measure of energy consumption or production over time, and it’s measured in watts (W). The wattage indicates the amount of electricity that gets used or generated in an hour, and it determines the performance of an electrical device or machine. For an appliance, the power consumption is calculated by multiplying the voltage and current used by the device, known as the electrical load.

Different devices consume different amounts of electricity to function, and the power rating indicates how many watts a device will use under normal operation. When you turn on a light, plug in your phone, or use a high-powered tool, the electrical current flows through wires and circuits, and the power consumption increases. Learning the basics of electrical power can help you understand your energy usage and reduce your electricity bills.

By using energy-efficient appliances and devices with lower wattage ratings, you can save on electricity costs, reduce carbon emissions and make smarter energy choices.

What Factors Affect Power Consumption?

Power consumption is the amount of energy used by electrical appliances or devices to carry out their functions. There are several factors that can affect power consumption, such as the type of appliance, its capacity, usage habits, and efficiency ratings. For example, larger appliances like refrigerators and air conditioners typically consume more energy than smaller devices like lamps and phone chargers.

How often an appliance is used, how long it runs, and the temperature and humidity of the surrounding environment can also impact its power consumption. Additionally, choosing energy-efficient appliances and devices can help reduce overall power consumption and save on electricity bills. By understanding the basics of power consumption, you can make informed decisions when selecting appliances and using them in a way that minimizes energy usage.

Calculating Power Consumption of Welding Machine

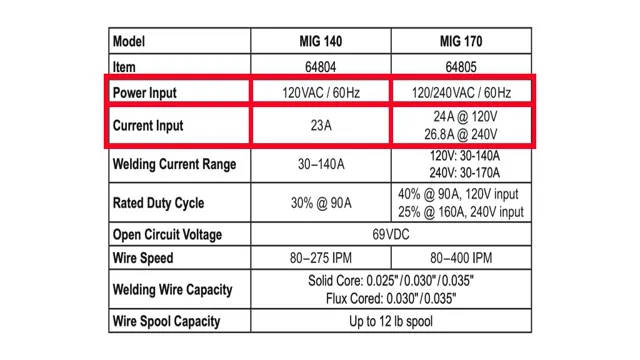

Calculating the power consumption of a welding machine is crucial in determining whether your electrical system can support it or not. To calculate the power consumption of a welding machine, you need to know the machine’s voltage, amperage, and duty cycle. You can find this information in the manufacturer’s manual or on the machine itself.

To calculate the power consumption, you need to use this formula: Power (in watts) = Voltage x Amperage. For instance, if your welding machine is rated at 240 volts and 60 amps, you would multiply them together to get 14,400 watts (240 x 60). The duty cycle is how long the machine can operate continuously without overheating or causing damage.

It is usually expressed as a percentage, such as 30%, 60%, or 100%. To determine the actual power consumption, you need to multiply the power by the duty cycle percentage. For example, if your machine’s duty cycle is 60%, the power consumption would be 8,640 watts (14,400 x 0.

60). It’s important to note that power consumption can vary depending on factors such as the type of welding, the material being used, and the thickness of the material. Therefore, it’s crucial to follow the manufacturer’s guidelines on power consumption, duty cycle, and other related information.

In conclusion, knowing how to calculate the power consumption of your welding machine is critical in ensuring your electrical system can handle it. Use the formula above by knowing the machine’s voltage, amperage, and duty cycle. Keep in mind that power consumption may vary, and it’s essential to follow the manufacturer’s guidelines.

Gather Information About the Welding Machine

Calculating power consumption of a welding machine is crucial when it comes to managing your energy bills and preventing burnouts. To determine the amount of electricity used by your welding machine, you need to gather important information such as the voltage, amperage, and duty cycle of the machine. The voltage is usually listed on the machine, and it refers to the level of electricity needed to power it.

The amperage, on the other hand, is the measure of electrical current flowing through the machine, which is important to consider because it affects the machine’s power consumption. Lastly, the duty cycle is the amount of time a welder can operate before it needs to cool down, which affects the machine’s overall energy usage. By multiplying the voltage, amperage, and duty cycle, you can determine the power consumption of the welding machine.

So, the next time you are using your welding machine, make sure to gather all the necessary data to calculate its power consumption and manage your energy efficiently.

Find the Power Rating of the Welding Machine

When it comes to finding the power rating of a welding machine, there are a few things you need to keep in mind. First and foremost, you need to know the voltage and amperage that the machine is rated for. Once you have that information, you can use a simple formula to calculate the power consumption of the machine.

Essentially, you just need to multiply the voltage by the amperage to get the wattage, which is the measure of power. For example, a welding machine that is rated for 220 volts and 20 amps would consume 4,400 watts of power. Keep in mind that this is just a rough estimate, as there may be other factors that can affect the power consumption of the machine, such as the duty cycle or the type of welding process being used.

However, by using this formula, you can at least get a good idea of how much power your welding machine is consuming, which can help you make more informed decisions about your energy usage and costs.

Calculate the Power Consumption

Welding is one of the most used processes in construction and manufacturing industries today. Whether you’re a professional welder or just someone interested in welding as a hobby, it’s essential to know how much power your welding machine consumes. Power consumption is an important factor to consider as it can affect your electricity bills and the environment.

To calculate the power consumption of your welding machine, you need to know its rated power and the duty cycle. The rated power is the maximum power output of the welding machine, while the duty cycle is the percentage of time the machine can operate continuously without overheating. To calculate the power consumption, multiply the rated power by the duty cycle and then multiply that result by the time you will spend welding.

For example, if your welding machine has a rated power of 180 amps and a duty cycle of 30%, you would multiply 180 by 0.3, which gives you 54 amps. This means you can weld for 3 minutes out of every 10 before letting the machine cool down.

The amount of electricity consumed during this time will depend on how long you plan to use the welding machine. By understanding the power consumption of your welding machine, you can make informed decisions and save money in the long run.

Tips for Reducing Power Consumption

When it comes to welding machines, calculating power consumption is crucial if you want to reduce energy costs and save money in the long run. One simple way to do this is to check the machine’s power rating, which is usually measured in watts or amperes. Once you know the power rating, you can calculate the energy consumption by multiplying it by the hours of use and the cost of electricity in your area.

Another useful tip is to choose a machine with an energy-efficient design and features such as automatic shut-off or standby mode when not in use. You can also reduce power consumption by keeping the machine clean and well-maintained, optimizing your welding process by choosing the right settings, and avoiding unnecessary idle times. With these tips, you can become a more eco-friendly and cost-effective welder while still achieving your welding goals.

Select a Welding Machine with Higher Efficiency

Welding machines play a critical role in many industrial processes, and selecting an efficient one can help save on power consumption and reduce costs. One key tip for reducing power consumption when selecting a welding machine is to look for models with a higher rating for efficiency. This means that the welding machine will convert more of the electrical power it uses into welding heat, resulting in less energy wastage.

Another way to increase efficiency is to consider a machine with advanced energy management features, such as automatic machine shut-off or adjustable voltage settings. By selecting the right machine and using it in the most efficient way possible, welding processes can be performed in a more sustainable, cost-effective manner.

Use Appropriate Welding Technique

When it comes to welding, using the appropriate technique not only ensures a high-quality weld but also reduces power consumption. One important tip for reducing power consumption is to use the smallest welding wire possible that still meets the project’s requirements. Using a larger wire than necessary not only wastes power but also creates unnecessary heat, increasing the risk of welding defects.

Additionally, adjusting the voltage and amperage according to the material’s thickness and joints’ design can also improve power efficiency. Welding in shorter intervals can help avoid overheating, reducing the need for power-hungry cooling systems and ultimately saving energy. By following these tips and choosing the appropriate welding technique, you can optimize your power consumption and create high-quality welds that stand the test of time.

Conclusion

In conclusion, while calculating the power consumption of a welding machine may seem like a daunting task, it’s actually simpler than it appears. By considering the welding process, duty cycle, and input voltage, you can accurately determine the amount of power needed to complete the job. If you’re still feeling lost, just remember: measuring power isn’t rocket science.

But with the right calculations, you can make sparks fly with ease.”

FAQs

What factors affect the power consumption of a welding machine?

The power consumption of a welding machine depends on factors such as the welding current, voltage, duty cycle, and electrode type.

How do I calculate the power consumption of my welding machine?

You can calculate the power consumption of your welding machine by multiplying the welding voltage by the welding current and then multiplying that value by the duty cycle (as a percentage).

Is there a difference in power consumption between MIG and TIG welding machines?

Yes, MIG welding machines tend to consume more power than TIG welding machines due to their higher amperage and duty cycle.

Can I reduce the power consumption of my welding machine?

Yes, you can reduce the power consumption of your welding machine by using a lower amperage setting, shorter duty cycle, and selecting an electrode with a lower power requirement.

What is the typical power consumption for a home welding machine?

The typical power consumption for a home welding machine is around 120V and 20-30 amps, resulting in a power consumption of 2.4-3.6 kW.

Does the type of metal being welded affect the power consumption of a welding machine?

Yes, the type of metal being welded can affect the power consumption of a welding machine as some metals require more heat and power to weld than others.

How does the power consumption of a welding machine affect my electricity bill?

The power consumption of a welding machine can significantly impact your electricity bill, especially if you use the machine frequently or for long periods of time. It is important to consider power consumption when selecting a welding machine and to use it efficiently to minimize costs.