Have you ever wondered what duty cycle means when it comes to welding machines? It’s an important factor to consider when purchasing or using a machine, as it can affect the overall efficiency and longevity of the welder. Duty cycle represents the amount of time a welding machine can run continuously before it needs to cool down. It’s typically measured as a percentage of a 10-minute cycle, with the duty cycle indicating how many minutes out of that 10 a welder can operate without overheating and potentially causing damage to the machine or the weld.

Understanding the duty cycle of your welding machine is crucial for ensuring that you don’t exceed its limits and cause damage, as well as for maximizing its efficiency and productivity. In this blog post, we’ll discuss how to calculate the duty cycle of your welding machine and explore some tips for optimizing its usage. So, let’s dive in!

What is duty cycle?

Duty cycle is a term commonly used in welding and refers to the percentage of time a welding machine can perform at its maximum output before it needs to cool down. Understanding the duty cycle is important to ensure the safety and durability of the equipment and the quality of the welds. To calculate the duty cycle of a welding machine, you need to consider the amperage and the time.

For example, if a welding machine has a 60% duty cycle at 200 amps, it means that it can weld continuously for 6 minutes out of every 10 minutes at that amperage before it needs to cool down for the remaining 4 minutes. It’s important to note that exceeding the duty cycle can cause damage to the equipment and create unsafe conditions. Always refer to the manufacturer’s guidelines to determine the appropriate duty cycle for your welding machine and adjust accordingly to ensure a safe and efficient welding process.

Definition and importance

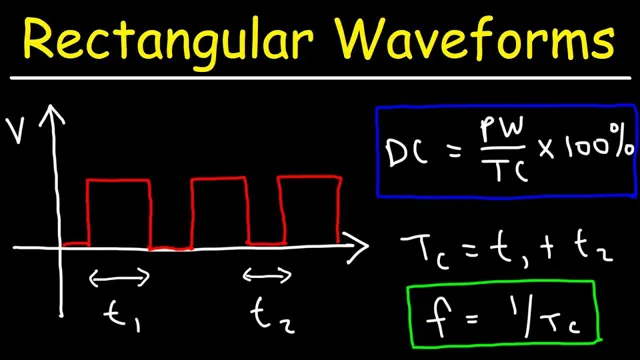

Duty cycle is a term used to describe the ratio of time a device or system is actively performing its intended function compared to the total time in a given period. For example, if a machine runs for 30 minutes then is idle for another 30 minutes, it has a duty cycle of 50%. In the world of electronics, duty cycle is a crucial parameter that governs how long a device can operate before taking a break to prevent overheating or wear and tear.

This is especially important in power electronics where high-frequency switching can lead to significant heat generation. High duty cycles can cause thermal damage, while low duty cycles can lead to inaccurate or incomplete performance. In short, duty cycle helps us to understand how efficiently a device is working and allows us to regulate its usage to prolong its lifespan.

Duty cycle formula

If you’re working with a welding machine, it’s essential to know the duty cycle formula so you can avoid overheating the equipment. Duty cycle is the percentage of time you can weld continuously within a 10-minute period before the welding machine needs to cool down. To calculate the duty cycle of your welding machine, you need to know the amperage required for your welding project and the maximum amperage rating of your machine.

For example, if the maximum rating is 200 amps and your welding project requires 100 amps, the duty cycle formula would be calculated as follows: 100/200 x 100 = 50%. This means you can weld continuously for five minutes before allowing your machine to cool down for the next five minutes. It’s crucial to follow the duty cycle to prevent equipment damage and ensure safe and efficient welding.

Happy welding!

Understanding the equation

When it comes to understanding the duty cycle formula, it can sometimes seem daunting at first. However, it’s an important concept to comprehend, particularly if you’re working with electronic devices. The formula itself is relatively simple: duty cycle = (on time / (on time + off time)) x 100.

Essentially, this formula calculates the percentage of time that a device is on compared to the time that it’s off. So, for example, if a device is on for five seconds and off for five seconds, the duty cycle would be 50%. Why does this matter? It’s essential to know the duty cycle when working with electronic devices because it can affect how much energy is consumed and how long the device can last.

Understanding the duty cycle formula is an important step in working with electronic devices, and it can impact a device’s overall efficiency and functionality.

Determining machine amperage

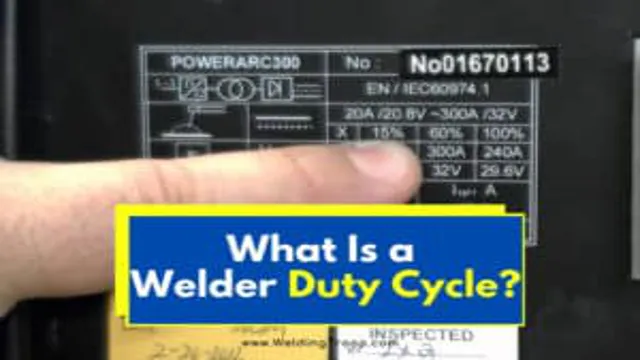

If you’re wondering how to calculate the duty cycle of your welding machine, the first step is to determine its amperage. This is important because a machine’s duty cycle will depend on its amperage capacity. To do this, you’ll need to look at the machine’s specifications or its nameplate.

The machine’s amperage rating will be listed here and it will tell you the maximum amount of current the machine can handle. Once you know your machine’s amperage rating, you can then calculate its duty cycle. Duty cycle refers to the amount of time the machine can be operated continuously out of a 10-minute cycle before it needs to cool down.

This is expressed as a percentage, so if your machine has a duty cycle of 60%, it means it can be used for 6 minutes out of every 10 before it needs to cool down for the remaining 4 minutes. By understanding how to determine your machine’s amperage and duty cycle, you can safely and effectively use your welding machine for your projects.

Factors that influence welding amperage

Determining the right amperage for your welding machine is essential to ensure a successful welding process. Several factors influence welding amperage, including the thickness of the metal being welded, the type of electrode used, and the welding position. It’s important to select the right machine amperage that will provide enough heat to melt the base metal and the electrode while not exceeding the metal’s melting point.

Fortunately, most welding machines come with a chart or table that suggests the appropriate amperage setting based on the thickness and type of metal to be welded. It’s important to note that using higher amperage than recommended can lead to a weak weld, while using lower amperage can result in incomplete fusion. With some practice, you will learn how to adjust the machine’s amperage to suit different welding situations and create a robust and durable weld.

Determining machine duty cycle

When it comes to determining the duty cycle of a welding machine, it is essential to understand the concept of duty cycle first. In essence, the duty cycle of a welding machine refers to the amount of time a machine can operate within a 10-minute period before it needs to stop to cool down. For instance, a welding machine with a 60% duty cycle means that it can operate for 6 minutes within a 10-minute period, while the remaining 4 minutes are cooling time.

To calculate the duty cycle of a welding machine, you must find the rated output of the machine as given by the manufacturer. Once you have established this, you can then divide the rated output by ten to get the rated amperage per minute. From there, you can multiply the rated amperage by the percentage duty cycle indicated on the machine to determine how long the machine can operate before needing cooling time.

Knowing your machine’s duty cycle is crucial in preventing it from overheating, which can lead to costly repairs and machine downtime.

Calculating the duty cycle percentage

Calculating the duty cycle percentage is an important factor in determining the efficiency and productivity of your machine. The duty cycle is the amount of time a machine can operate continuously before it needs to rest and cool down. For example, if a machine has a duty cycle of 50%, that means it can run for 30 minutes out of every hour without overheating.

To calculate the duty cycle percentage, you need to divide the total operating time by the total cycle time. Then, multiply the result by 100 to get the percentage. For instance, if a machine can run for 20 minutes and needs 40 minutes to rest, the duty cycle percentage will be 33%.

It’s crucial to ensure your machine’s duty cycle percentage is within its recommended limit to avoid damage and maximize its lifespan.

Interpreting duty cycle ratings

As a welder, it’s important to understand the duty cycle of your machine. Duty cycle is the amount of time a welding machine can operate in a 10-minute period before it needs to cool down. To calculate the duty cycle of your welding machine, simply divide the length of time you can weld by the cycle time (usually 10 minutes) and multiply by 100.

For example, if you can weld for 6 minutes without interruption, your duty cycle would be 60%. This means that you can weld for 6 minutes and need to allow the machine to cool for the remaining 4 minutes. It’s important to note that duty cycle can vary depending on factors such as the amperage setting and the ambient temperature.

Always refer to your machine’s manual or consult a professional if you have any questions about its duty cycle. By understanding duty cycle, you can ensure that your welding machine operates efficiently and stays in good working condition.

What ratings indicate and their significance

Interpreting duty cycle ratings can be a bit confusing, but it is important to understand what they mean to ensure that you are using your equipment safely and effectively. Duty cycle refers to the amount of time that a machine can operate before it needs to cool down. This is typically expressed as a percentage, such as 50% or 100%.

For example, if a welding machine has a duty cycle rating of 50% at 200 amps, it means that it can operate at 200 amps for 5 minutes before it needs to cool down for an equal amount of time. Understanding duty cycle ratings is critical because if you exceed the duty cycle, the machine can overheat and become damaged, which can be dangerous and costly. Therefore, it is crucial to choose a machine with a duty cycle that suits your needs and to take breaks when necessary to allow the machine to cool down.

Maintaining optimal duty cycle

If you’re a welding enthusiast, you need to understand how to calculate the duty cycle of your welding machine to maintain optimal performance. Duty cycle refers to the percentage amount of time a welder can safely operate within a ten-minute period without overheating and causing damage to the machine’s components. For example, a welder with a duty cycle of 50% can operate for five minutes before needing a five-minute break to cool down.

To calculate the duty cycle of a welding machine, divide the total operating time by the total cycle time and multiply the result by 100. It’s crucial to choose a welding machine that can handle your workload without overheating to maintain optimal performance. Therefore, ensuring that you calculate the duty cycle correctly before purchasing a welding machine can save you from downtime and other issues.

Tips for prolonging machine lifespan

One of the most important factors for prolonging a machine’s lifespan is maintaining its optimal duty cycle. What is a duty cycle, you ask? Well, a machine’s duty cycle refers to the number of pages or jobs it can handle per month without being overworked. Exceeding this limit can lead to overheating, component failures, and ultimately, a shorter lifespan for your machine.

So, how do you maintain the optimal duty cycle? It’s essential to follow the manufacturer’s recommendations for your specific machine and use it accordingly. For example, if your machine’s duty cycle is 10,000 pages per month, try to limit its usage to this number or less, and avoid running it continuously for extended periods. Remember, giving your machine a break and letting it cool down can go a long way in ensuring a longer lifespan for your equipment.

Conclusion

In conclusion, calculating the duty cycle of a welding machine is a crucial step in ensuring you get the most out of your welding project. Simply put, it is the ratio of welding time to the total time the machine can operate before needing to cool down. Think of it like a marathon runner – you want to pace yourself and not overwork your machine to avoid overheating and potential damage.

With a little bit of math and attention, you’ll be able to weld away without any hiccups, and your welding machine will thank you for it!”

FAQs

What is duty cycle in welding machines?

Duty cycle is the percentage of time that a welding machine can operate continuously within a 10-minute period without overheating.

How is duty cycle calculated?

Duty cycle is calculated by dividing the actual welding time by the total time in a 10-minute period, then multiplying by 100.

What is a good duty cycle for a welding machine?

A good duty cycle for a welding machine depends on the intended use. For light-duty applications, a duty cycle of 20% is typically sufficient, while heavy-duty applications may require a duty cycle of 40% or higher.

How does duty cycle affect productivity in welding?

Duty cycle affects productivity in welding by determining the amount of welding that can be done within a given time period. A higher duty cycle allows for longer welding times and higher productivity.

What factors affect a welding machine’s duty cycle?

Factors that affect a welding machine’s duty cycle include ambient temperature, welding current, electrode size and type, and the machine’s cooling system.

Can a welding machine’s duty cycle be improved?

A welding machine’s duty cycle can be improved by using electrodes with less current draw, improving the cooling system, reducing ambient temperature, and decreasing the welding current.

How important is duty cycle when selecting a welding machine?

Duty cycle is an important consideration when selecting a welding machine, as it directly affects the machine’s performance and productivity. Choosing a machine with a suitable duty cycle for the intended use can help ensure that the work is completed efficiently and effectively.