Have you ever found yourself in need of a reliable and versatile tool for everyday use in your kitchen? If so, a utility knife may be just what you’re looking for. These all-purpose knives are known for their ability to handle a variety of cutting tasks, including slicing, dicing, and chopping with ease. But if you’re considering adding a utility knife to your cooking arsenal, you may be wondering: how thick is a utility knife blade, and does it affect its performance? The thickness of a utility knife blade can vary depending on the brand and model, but generally falls within the range of

5mm to 3mm. This may seem relatively thin compared to other types of knives, such as cleavers or Santoku knives, which typically have thicker blades for tasks that require more force. However, the thinness of a utility knife blade does not compromise its strength or durability.

In fact, it’s what makes the knife so agile and versatile in the kitchen. Imagine trying to slice a tomato with a thick and heavy blade, like a cleaver. The blade would likely crush the fruit before it could make a clean cut.

A utility knife, on the other hand, with its thin and sharp blade can easily glide through the tomato’s skin and flesh. Similarly, a thicker blade on a utility knife would not be practical for tasks that require precision, or for tasks that involve intricate cuts. So, in summary, a utility knife blade typically ranges between

5mm and 3mm in thickness, which allows for a balance of agility and strength. Don’t let its thinness fool you – a well-made utility knife can handle a variety of kitchen tasks with ease and precision.

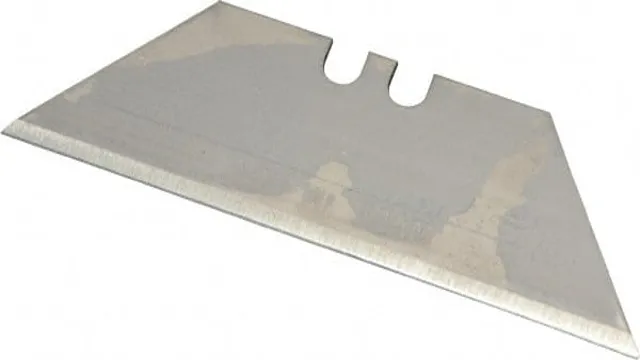

Understanding the Anatomy of a Utility Knife Blade

Utility knives are a popular tool for many DIY enthusiasts and professionals, and the thickness of the blade is an important factor to consider. Generally, the thickness of a utility knife blade ranges from 0.5mm to

5mm, depending on its purpose and manufacturer. A thinner blade provides greater precision and maneuverability, but it may not be suitable for heavy-duty tasks. On the other hand, a thicker blade is more durable and can handle tougher materials, but it may sacrifice some flexibility and control.

Ultimately, the ideal thickness of a utility knife blade depends on your specific needs and preferences. Whether you are using a utility knife for cutting cardboard, slicing through drywall, or carving wood, make sure to choose a blade thickness that suits the task at hand. By understanding the anatomy of a utility knife blade, you can make an informed decision and get the most out of your tool.

Blade Width Vs. Blade Thickness

When it comes to understanding the anatomy of a utility knife blade, it’s important to know the difference between blade width and blade thickness. Blade width is the distance from one side of the blade to the other, while blade thickness is the measurement of the blade’s thickest section. Both factors play a role in the blade’s strength and flexibility.

A wider blade may give a cleaner cut, but a thicker blade may be more durable and withstand more pressure when cutting through tough materials. It’s important to consider the intended use of the utility knife when deciding on blade width and thickness. For example, a thinner blade may be more suitable for intricate cutting tasks, while a thicker blade would be better for heavy-duty cutting jobs like construction work.

By understanding the difference between blade width and thickness, you can choose the right utility knife blade for your needs.

Common Thickness Range for Utility Knife Blades

When it comes to utility knife blades, it’s important to understand their anatomy and common thickness range to find the right blade for your needs. The blade of a utility knife consists of the cutting edge, spine, and tang. The cutting edge is the sharp part of the blade used for cutting, while the spine is the thicker, duller part of the blade opposite the cutting edge.

The tang is the part of the blade that extends into the handle for stability. The common thickness range for utility knife blades is between 0.5mm and 1mm.

Blades on the thicker end of the range are sturdier and better suited for heavy-duty tasks, while blades on the thinner end are more agile and better suited for precision work. Ultimately, the thickness of the blade you choose will depend on the tasks you need to perform with your utility knife. By understanding the anatomy of the blade and its common thickness range, you can choose the blade that will work best for you.

Factors Affecting Blade Thickness

When it comes to utility knife blades, their thickness can vary depending on a variety of factors. One of the main determinants is the type of material used for the blade’s construction. For instance, blades made from high-carbon stainless steel can be thicker than those made from other materials.

Another factor is the intended use of the knife, with thicker blades typically being better suited for heavier-duty tasks such as cutting through tough materials like leather or thick cardboard. Additionally, the overall size and shape of the knife can also play a role in determining the blade’s thickness, with larger knives generally having thicker blades than smaller ones. Ultimately, the ideal blade thickness for a utility knife will depend on factors such as the user’s preferences and the specific tasks that the knife will be used for.

However, regardless of the thickness, a well-made utility knife with a sharp blade can be an invaluable tool in a variety of situations.

Type of Material Used

When it comes to blade thickness, there are several factors to consider. One of the most important factors is the type of material used to make the blade. Different materials have different properties that can affect the blade’s thickness.

For example, a blade made of high-carbon steel will typically be thinner than a blade made of stainless steel. This is because high-carbon steel is harder and more durable than stainless steel, which means it can be ground down to a finer edge without losing its strength. Another factor to consider is the intended use of the blade.

A thinner blade may be more appropriate for slicing or precision cuts, while a thicker blade may be necessary for chopping or heavy-duty tasks. Overall, the type of material used for a blade plays a crucial role in determining its thickness and ultimately its performance.

Intended Use of the Knife

When it comes to choosing the appropriate blade thickness for a knife, the intended use of the knife is a critical factor to consider. A kitchen knife used for chopping vegetables, for example, requires a thinner blade for precision cutting and slicing. On the other hand, hunting and survival knives should have a thicker blade for more robust and durable performance.

The material used to make the blade is also a factor that affects blade thickness. Stainless steel blades are usually thinner than carbon steel blades due to their softer nature. However, a thicker carbon steel blade can still be used in cutting hard materials with ease.

The intended use of the knife is the deciding factor in choosing the appropriate blade thickness.

Personal Preference

When it comes to blade thickness, it all comes down to personal preference. Some people prefer thicker blades, while others like thinner ones. There are various factors that can influence this preference, such as the type of cutting task you have at hand, your experience level, and the type of knife you are using.

Thicker blades are generally more durable and can handle tougher tasks, such as chopping through bones or harder vegetables. However, they may not be as sharp and agile as thinner blades, which are ideal for precision tasks like filleting or slicing. Ultimately, the key is to find a blade thickness that feels comfortable to you and suits your needs.

Whether you opt for thicker or thinner blades, always remember to prioritize safety and proper knife handling techniques to avoid accidents in the kitchen.

Choosing the Right Blade Thickness for Your Needs

If you’re in the market for a utility knife, you may be wondering how thick the blade should be. Well, the answer depends on your specific needs and preferences. For general use, a blade thickness between

5-5mm is common. Thinner blades (

5mm) are better suited for tasks that require precision and finesse, such as peeling vegetables, while thicker blades (5mm) are better suited for tougher jobs, such as cutting through meat and bone. However, if you’re looking for a heavy-duty knife, you may want to consider a blade thickness of 3mm or more, which can handle even the toughest cutting and chopping tasks with ease.

Ultimately, the right blade thickness for you will depend on what you plan to use your utility knife for.

Consider the Type of Cutting Task You’ll Be Doing

When it comes to choosing the right blade thickness for your cutting needs, it’s important to consider the type of cutting task you’ll be doing. If you’ll be working with thicker materials, such as hardwood or metal, you’ll want to opt for a thicker blade. Thicker blades can handle more force and are less likely to break or bend during use.

On the other hand, if you’ll be working with softer materials, such as fabric or foam, a thinner blade may be more appropriate. Thinner blades can make more precise cuts and are easier to maneuver. It’s important to strike a balance between thickness and flexibility, ensuring that your blade can handle the job at hand without being too cumbersome or delicate.

By considering your specific cutting needs and the materials you’ll be working with, you can choose a blade thickness that’s just right for you.

Take Your Experience and Skill Level into Account

When it comes to choosing the right blade thickness for your needs, it’s important to take your experience and skill level into account. If you’re new to cutting or slicing, a thinner blade might be easier to handle and provide better control. On the other hand, if you have more experience, a thicker blade might be more suitable for heavier tasks and tougher materials.

It’s also important to consider what you’ll be using the blade for. If you’re primarily chopping vegetables or filleting fish, a thinner blade would be more precise. However, if you’re cutting through dense meats or bones, a thicker, sturdier blade would be better equipped for the job.

Ultimately, your comfort and competency with the blade should guide your decision, and you may want to try out a few different thicknesses to find the perfect fit for your needs.

Conclusion

In conclusion, the thickness of a utility knife blade can vary depending on its intended use and the materials it’s designed to cut through. Some utility knife blades may be as thin as a hair, while others may be as thick as a steak knife. But let’s be real, no matter how thick or thin the blade is, the true measure of its usefulness lies in the hands of the person wielding it.

So, don’t worry about the thickness of your utility knife blade – just focus on honing your cutting skills and slicing through whatever comes your way like a boss.”

FAQs

What is the typical thickness of a utility knife blade?

The typical thickness of a utility knife blade is around 0.025 to 0.030 inches.

Can the thickness of a utility knife blade affect its performance?

Yes, a thicker blade may be more durable, but a thinner blade may be sharper and better for precision cutting tasks.

Are utility knife blades made from different materials?

Yes, utility knife blades can be made from various materials such as carbon steel, stainless steel, and ceramic.

What is the difference between a straight edge and a serrated edge utility knife blade?

A straight edge utility knife blade is better for slicing and cutting through softer materials, while a serrated edge is best for sawing through tough or fibrous materials.

Can utility knife blades be sharpened?

Yes, utility knife blades can be sharpened using a sharpening stone or a honing rod.

How often should I replace my utility knife blade?

It depends on how frequently you use your utility knife, but it’s recommended to replace the blade when it becomes dull or damaged.

Are there safety precautions I should follow when handling a utility knife blade?

Yes, always handle the blade with care and keep it away from children. When not in use, store the blade in a safe place and use a protective sheath if available.