You’ve just finished staining your new project and are ready for the final step: applying polyurethane. But wait, when is it safe to apply polyurethane after staining? Rushing the application process can lead to unsatisfactory results, and nobody wants to waste their time and effort on a subpar finish. Just like any task, it’s important to follow the proper procedure for the best outcome.

Applying polyurethane too soon after staining can cause the stain to lift and bleed, resulting in a blotchy appearance. On the other hand, waiting too long can also cause problems. The longer you wait, the more susceptible your project is to dirt and debris settling on the surface, causing a lackluster finish.

So, what’s the ideal waiting time? Generally, it’s recommended to wait 24-48 hours after staining before applying polyurethane. However, this may vary depending on the type of stain and environmental factors such as temperature and humidity. Remember, patience is key when it comes to finishing your project.

Rushing the process can result in disappointing results, while following the proper steps and waiting for the appropriate amount of time will lead to a smooth and flawless finish.

Understanding the Staining Process

If you’ve recently stained wood and are wondering how soon after staining can you apply polyurethane, there are a few things to keep in mind. It’s important to understand the staining process before applying any type of topcoat. Staining wood involves applying a pigmented solution to the surface, allowing it to penetrate the wood, and then wiping away any excess stain.

The drying time can vary depending on the type of stain and the humidity level, but as a general rule, you should wait at least 24 hours before applying polyurethane. This will allow the stain to fully dry and cure, and prevent the polyurethane from reacting with the uncured stain. Rushing the process can lead to a less-than-perfect finish, so take your time and allow the staining process to fully complete before moving on to the next step.

Types of Stains

When it comes to understanding the staining process, it’s important to know the different types of stains that exist. There are two main categories: organic and inorganic. Organic stains come from materials such as food, blood, or urine, while inorganic stains are caused by things like rust or hard water deposits.

The key difference between the two is that organic stains contain carbon, while inorganic stains do not. Understanding the type of stain you’re dealing with can help you determine the best way to remove it. For instance, organic stains are typically best treated with enzyme or oxygen-based cleaners that break down the organic matter.

Inorganic stains, on the other hand, may require an acid-based cleaner to dissolve the mineral deposits. By identifying the type of stain, you can save time and money by using the most effective method for removing it.

Drying Times for Stains

Understanding the Staining Process: Drying Times for Stains Stains can be a frustrating and often unavoidable part of life. Whether it be a spill on your favorite shirt or a mark on your countertop, the process of removing a stain can seem daunting. Understanding the staining process, however, can help make the task a bit easier.

When a stain occurs, it is typically a result of a substance penetrating the surface it has come into contact with. This can include liquids such as coffee or juice, as well as materials like ink or dirt. The amount of time it takes for a stain to dry depends on a variety of factors, including the type of substance, the temperature and humidity of the surrounding environment, and the absorbency of the surface it has come into contact with.

Some stains may dry relatively quickly, such as those made by water or alcohol-based substances. Others, like those made by oil or grease, may take longer to dry and are also more difficult to remove. In some cases, the longer a stain is left to dry, the more difficult it may be to remove.

To help prevent stains from setting in, it is important to act quickly and use the appropriate cleaning method for the particular substance. This may involve blotting the stain with a clean cloth, applying a cleaning solution, or utilizing a stain remover product. It is also important to take steps to protect surfaces from staining, such as using coasters and place mats on tables, and avoiding bringing certain substances near fabrics or delicate surfaces.

Overall, understanding the staining process and how drying times can impact the removal of a stain can help make the task of stain removal less daunting. With proper care and quick action, many stains can be effectively removed without causing long-term damage to the affected surface.

The Role of Polyurethane

If you’re on the hunt for an answer to the question of how soon after staining you can apply polyurethane, you’ve come to the right place. The general rule of thumb is that you can apply polyurethane once the stain has had time to dry completely. However, the exact timeline will vary depending on factors like the type of stain, the type of wood you’re working with, and the weather conditions in your area.

It’s important to keep in mind that applying polyurethane too soon can result in the stain bleeding or smearing, and applying it too late can lead to improper adhesion. In general, it’s best to wait at least 24 hours after staining before applying polyurethane, and to always follow the manufacturer’s recommendations. When in doubt, it’s always a good idea to test a small inconspicuous area first to ensure that the polyurethane adheres properly.

Why Apply Polyurethane

Polyurethane is a type of polymer with countless applications due to its unique properties. Its versatility makes it a popular choice in various industries, including construction, automotive, and footwear. Polyurethane is known for its durability, flexibility, and resistance to chemicals and abrasion.

Applying polyurethane to surfaces improves their strength, durability, and ability to withstand wear and tear. It also provides a protective layer that resists moisture, making it ideal for use in outdoor or wet environments. If you want to protect your floors, furniture, or any other surface that is subject to heavy use, then applying polyurethane is a smart choice.

Not only will it make the surface more robust, but it will also enhance its appearance and extend its lifespan.

Types of Polyurethane

Polyurethane plays a crucial role in a variety of industries due to its versatility and durability. Polyurethane is a polymer made of units linked together by carbamate (urethane) links. It comes in different forms such as flexible foam, rigid foam, coatings, adhesives, and elastomers.

Flexible foam is used in furniture and bedding, while rigid foam is used in insulation and packaging. Coatings and adhesives are used in building and construction, while elastomers are used in wheels, tires, and seals. Each type of polyurethane has its unique properties and can be customized for specific applications.

The polyurethane industry is constantly evolving, and new technological advancements are being made to make it even more sustainable and eco-friendly. As the world focuses more on sustainability, the role of polyurethane in manufacturing will undoubtedly continue to expand.

Application Tips

When it comes to applications that require durability, polyurethane plays an essential role. This thermosetting polymer offers excellent mechanical properties, making it ideal for industries ranging from automotive to construction. When applied, polyurethane creates a protective barrier that can withstand abrasion, impact, and moisture.

Its chemical resistance also prevents damage from chemicals and other solvents. In addition to its physical properties, polyurethane is cost-effective and can be easily molded into various shapes and sizes. With its versatility, polyurethane can be used in coatings, adhesives, foams, and much more.

Overall, polyurethane’s unique properties make it an excellent choice for industries that require a strong, durable, and long-lasting material.

When Can You Apply Polyurethane After Staining?

If you’re looking to protect your stained wood with polyurethane, you might wonder how soon after staining you can apply it. As a general rule, you should wait at least 24 hours before applying polyurethane to stained wood. It’s essential to ensure that the stain is completely dry before you apply polyurethane; otherwise, the polyurethane won’t adhere correctly to the surface.

Waiting for a full day also lets any solvent or chemicals in the stain evaporate, preventing any bubbling or blistering in the polyurethane’s final coat. However, it’s vital to read the stain manufacturer’s instructions to determine the minimum drying time and timing guidelines that they recommend for your particular type of stain. Rushing the process might result in unsatisfactory results or even damage to the wood surface.

Factors that Affect Drying Time

Polyurethane, drying time, staining If you’re planning to apply polyurethane after staining your wood, it’s essential to know when you can start the process. One of the critical factors that affect drying time of polyurethane is humidity. High humidity levels can cause the finish to dry slower than usual while low humidity levels might speed up the process.

Additionally, the type of stain used plays a significant role in the time it takes for the wood to dry. Oil-based stains can take up to 24-48 hours to dry completely, while water-based stains take less time, usually around 4-6 hours. Another factor is the application method used, as roller or brush application can be more time-consuming compared to spraying.

It’s important to note that applying polyurethane before the stain has completely dried can cause the finish to blur or bubble. Therefore, it’s essential to wait for the recommended waiting period before applying the polyurethane. Ultimately, allowing ample drying time for your stain and polyurethane application will ensure a beautifully finished wood surface with a long-lasting, durable finish.

Recommended Wait Time

Polyurethane, staining, wait time If you’re planning to stain your wooden furniture or floors, it’s essential to know how long you should wait before applying polyurethane. Generally, you should wait at least 24-48 hours after staining to apply the polyurethane. However, it’s important to make sure that the stain is completely dry before applying polyurethane.

If you apply polyurethane too soon after staining, the finish may not adhere correctly, resulting in patches and bubbles. Therefore, it’s always best to wait for the recommended time before applying polyurethane. It’s worth noting that factors like temperature and humidity can also affect the drying time of stain and polyurethane.

So, it’s best to follow the manufacturer’s instructions for both the stain and polyurethane products you’re using. By doing so, you’ll ensure a durable and beautiful finish for your wooden furniture or floors.

Conclusion

In conclusion, the answer to the age-old question of how soon after staining can you apply polyurethane is simply this: it depends. You may be able to apply polyurethane to your freshly stained surface in as little as six hours, or you may need to wait up to 24 hours for the stain to fully dry and cure. Ultimately, patience is key when it comes to achieving a flawless finish.

So, gather your favorite snacks, a good book, and settle in for the wait until your stain is ready for its final polyurethane coat. Your patience will be rewarded with a stunning, long-lasting finish that will last for years to come. Happy staining!”

FAQs

What are the steps to prepare a wood surface for staining and polyurethane application?

The surface must be sanded, cleaned, and free of any debris before stain application. Once the stain has dried according to the manufacturer’s instructions, polyurethane can be applied.

How many coats of polyurethane should be applied over the stained surface?

Typically, two to three coats of polyurethane are recommended to protect and seal the stained surface.

Can polyurethane be applied over a water-based stain?

Yes, polyurethane can be applied over water-based stain as long as it is completely dry and cured before application.

Is it necessary to sand between coats of polyurethane?

Yes, it is recommended to sand lightly with a fine-grit sandpaper between each coat of polyurethane.

How long should you wait before applying polyurethane after staining?

It is recommended to wait at least 24 hours after staining before applying polyurethane to ensure that the stain is completely dry and cured.

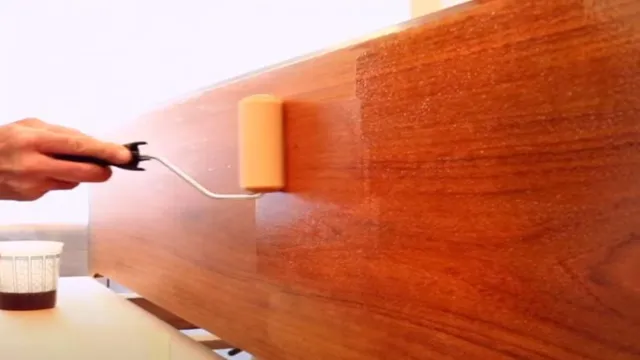

Can a brush or roller be used to apply polyurethane?

Both a brush and roller can be used to apply polyurethane, but a brush is typically recommended for better control and coverage.

Is it necessary to use a sealer before applying polyurethane over stained wood?

It is not necessary to use a sealer before applying polyurethane over stained wood, but it can help to enhance the stain color and provide additional protection.