Have you been considering buying a welding machine? Are you wondering if it’s going to be too heavy to move around? Welding machines come in different sizes and weights, and it can be challenging to find the right one that meets your needs. Understanding the weight of the welding machine is essential to determine how easy or difficult it will be to transport it from place to place. The weight of a welding machine depends on a few factors such as its size, power source, and welding process.

Some welding machines are relatively lightweight, while others can weigh over 100 lbs. The weight of a welding machine is especially important if you plan on transporting it to different work sites. It’s essential to choose a machine that you can easily carry around without straining your muscles.

In this blog post, we’ll discuss the different factors that influence the weight of a welding machine, and provide you with some examples of welding machines that vary in weight. By the end of this blog post, you’ll have a better understanding of what to look for in a welding machine, how much it might weigh, and which one suits your needs. So, let’s dive into the details to find out!

Understanding Welding Machines

If you’re planning to purchase a welding machine, you might be wondering how much it weighs. The answer to this question varies depending on the type of welding machine you’re looking at. For instance, a Stick or TIG welding machine can weigh anywhere from 15 to 50 pounds.

In contrast, MIG welding machines are heavier and can weigh between 50 and 100 pounds. However, some heavy-duty MIG welding machines can weigh more than 200 pounds. Therefore, it’s essential to consider the weight of the welding machine while choosing the right one for your needs.

If you’re looking for a portable welding machine, go for lighter machines with inverter-based technology. These machines are more compact and usually weigh less than traditional welding machines. Ultimately, the weight of the welding machine is a crucial factor to consider, but it should not be the only factor.

You must also consider the features, performance, and power requirements of the machine before making a purchase.

Types of Welding Machines

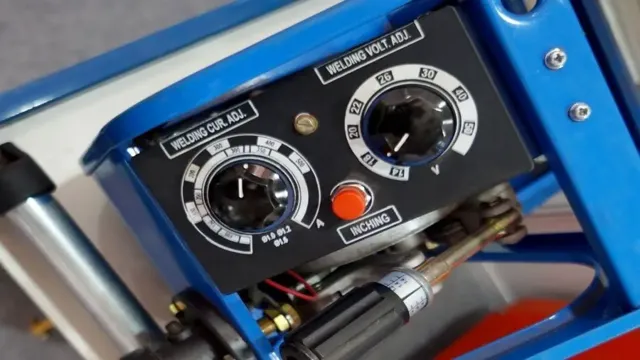

Welding machines come in different varieties, each with its unique features and capabilities. At their core, these machines use electric current to create an intense heat source that melts and binds metal parts together. Some of the most common types of welding machines include TIG, MIG, and Stick welders.

TIG welders use a tungsten electrode to heat the metal while MIG welders use a spool of wire to create a continuous arc. Stick welders, on the other hand, use a consumable electrode coated in flux to create the heat source. Before choosing a welding machine, it is important to consider the type of metal you will be working with, the thickness, and your welding experience level.

Factors like portability, input power, and duty cycle can also affect your decision. Ultimately, understanding the different types of welding machines will help you choose the right one for your project and achieve the desired results.

Factors Affecting Weight

When it comes to welding, the machine you use can have a significant impact on the outcome of your project. Understanding the different types of welding machines and their capabilities is crucial for achieving high-quality welds. There are three main types of welding machines: MIG, TIG, and stick welders.

MIG (metal inert gas) welding is best for beginner welders or those working with thin metals. TIG (tungsten inert gas) welding is ideal for precise work with thinner wires and produces a clean finished product. Stick welding is the most versatile and can handle thicker metals as well as outdoor conditions.

Additionally, it’s essential to consider the input voltage and duty cycle of the welding machine to ensure it can handle the demands of your project. By choosing the appropriate welding machine for the job and understanding its capabilities, you can achieve the best results possible.

Average Weight of Welding Machines

If you’re interested in buying a welding machine, you’re probably wondering how much they weigh. Well, the answer isn’t straightforward since welding machines come in different shapes and sizes. Generally speaking, though, the average weight of a welding machine is around 50 to 60 pounds, give or take a few pounds.

However, some portable models can weigh as little as 10 pounds, making them extremely convenient for DIYers or professionals who need to move around a lot. On the other hand, industrial-grade welding machines can weigh up to 1000 pounds or more, depending on the type and capacity of the machine. So, if you’re planning to purchase a welding machine, it’s essential to consider your needs, work environment, and the weight of the machine to ensure that it suits your requirements and preferences.

Arc Welding Machines

When considering purchasing an arc welding machine, one factor to take into account is the average weight of the machine. The weight can influence the portability and ease of use of the machine. The average weight of arc welding machines ranges between 50 to 80 pounds.

However, some machines can weigh as much as 100 pounds, while others weigh as little as 20 pounds. The size of the machine typically correlates with its weight. Larger machines tend to weigh more than smaller machines.

You should also consider the type of welding that will be done when selecting a machine, as the weight can vary depending on the welding process. MIG welding machines are typically heavier than TIG welding machines, for example. Ultimately, the weight of the machine should be considered in conjunction with other factors such as power, welding capabilities, and cost to make an informed decision about a welding machine that suits your specific needs.

MIG Welding Machines

When it comes to MIG welding machines, one of the things you need to consider is their weight. The average weight of MIG welding machines can vary based on different factors such as the power source, size, and brand. However, a typical MIG welding machine may weigh between 30 to 100 pounds, making them quite portable and easy to move around.

Some heavy-duty models of MIG welding machines may even weigh over 200 pounds due to their larger size and more powerful capabilities. The weight of a MIG welding machine is an important factor to consider if you need to transport it frequently, as a lighter machine can be easier to maneuver and set up, while heavier ones may require more effort to move around. Overall, the weight of MIG welding machines can vary, and it’s essential to choose the right weight based on your requirements and preferences.

TIG Welding Machines

When it comes to TIG welding machines, one of the most pressing concerns is their weight. With all the equipment and materials required for welding, it’s important to choose a machine that is both sturdy and portable. The average weight of a TIG welding machine varies depending on the model and brand, but it generally falls in the range of 40-80 pounds.

This might seem like a lot, especially if you need to transport your machine frequently, but it’s important to remember that a heavier machine often means higher quality and better durability. Additionally, some TIG welding machines come with wheels that make it easier to move them around. It’s also worth considering purchasing a welding cart to help transport your machine more easily.

Ultimately, the weight of your TIG welding machine will depend on your needs and preferences, but by doing your research and weighing the pros and cons of different models, you can find the perfect machine for your welding needs.

Portable vs Stationary Welding Machines

When it comes to welding machines, the weight can vary greatly depending on if it’s portable or stationary. If you’re looking to purchase a portable welding machine, you’ll be relieved to know that they tend to be much lighter than their stationary counterparts. Most portable welding machines weigh anywhere between 10 to 50 pounds, making them easy to move around and take to different job sites.

However, if you’re in need of a more heavy-duty welding machine that can handle larger projects, you’ll likely need to opt for a stationary machine. These machines can weigh anywhere from 200 to 800 pounds or more. While they may be difficult to move around, they offer more power and durability.

So, if you’re looking for a welding machine with more versatility and mobility, a portable machine will be your best bet. But if you need a machine that can handle more intense welding projects and provide greater amounts of power, a stationary machine will be the way to go.

Portable Welding Machines

Portable Welding Machines Portable welding machines are a popular option for welders, as they provide convenience and flexibility when it comes to moving between job sites. However, when choosing between a portable and stationary welding machine, it is important to consider the specific needs of your work. If you mainly work in a single location, a stationary welding machine may be a better option, as it is often more powerful and delivers a steadier arc.

On the other hand, if you require mobility and need to work on different job sites, a portable welding machine might be the better choice. These machines are compact, lightweight, and can often run on batteries or generators, allowing welders to work in areas without access to power sources. Ultimately, the decision between a portable and stationary welding machine depends on the demands of your work and your individual preferences.

So, weigh the pros and cons and choose the option that will best suit your needs.

Stationary Welding Machines

When it comes to welding machines, there are two main types to consider: portable or stationary. While portable welding machines offer flexibility and convenience, stationary ones have their own unique advantages. Stationary welding machines are permanently located in a shop or garage and offer consistent power output, making them a great choice for those working on large projects or requiring high welding production.

They can also accommodate a wider range of processes and have a greater capacity to handle heavier workloads. On the other hand, portable welding machines are ideal for those on the go or working on job sites, as they are lightweight and can be easily transported. They may not offer the same power output as stationary machines, but they are still capable of getting the job done when it comes to lighter welding tasks.

Ultimately, which type of welding machine to choose depends on your individual needs and preferences.

Conclusion

To anyone who ever wondered how much a welding machine weighs, the answer is simple yet complex. It depends on the specific machine in question, as factors such as its size, power, and design can significantly impact its weight. So the next time you find yourself pondering this important question, remember that the answer lies not in a universal number, but in the unique attributes of each individual machine.

And if you really want to know the weight of a particular welding machine, just consult its specifications or give it a lift yourself (if you’re feeling strong!). Happy welding!”

FAQs

What is the average weight of a welding machine?

The average weight of a welding machine is around 50-60 pounds.

How much does a portable welding machine weigh?

The weight of a portable welding machine varies according to its size and type, but on average it can weigh anywhere from 15 to 50 pounds.

What is the weight of a MIG welding machine?

The weight of a MIG welding machine can range from 50 to 100 pounds depending on the specific model.

What is the weight of a TIG welding machine?

TIG welding machines can vary in weight, but on average they are lighter than MIG welding machines, weighing around 40-60 pounds.

How heavy is a stick welding machine?

Stick welding machines are generally heavier than MIG and TIG machines, with an average weight of 80-100 pounds.

Are there lightweight welding machines available?

Yes, there are several lightweight welding machines available in the market that weigh as little as 10-15 pounds.

How does weight influence the portability of a welding machine?

The heavier the welding machine, the less portable it is. While a heavy machine may be more powerful, it can be difficult to move around and is not suitable for on-the-go projects.