How Does a Metal Lathe Work: Essential Guide to Understanding the Mechanics

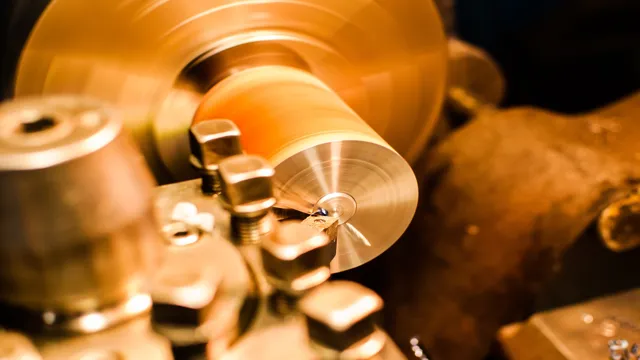

Have you ever wondered how metal parts, gears, or tools are created with their ultra-precise measurements? The answer is through the use of a metal lathe. A metal lathe is a powerful machine tool that can shape metal into a variety of shapes, including cylinders, cones, and spheres. This is achieved by rotating the metal piece on its axis while a cutting tool removes unwanted material.

The process of using a metal lathe may seem complicated at first, but it’s a fascinating method to watch in action. The operator manually controls the movement of the cutting tool, either by hand or through a computer numerical control system or CNC. The lathe’s rotating spindle can handle different sizes of metal pieces, and the cutting tool can create a range of different shapes from the metal.

The process of using a metal lathe is similar to carving a piece of wood or sculpting with clay. Like an artist, an operator must carefully control the cutting tool, while being mindful of the metal’s density, thickness, and hardness. In the end, the results of using a metal lathe can be stunning, with perfectly formed components or entire machines that can perform at high levels.

In this blog series, we’ll take a deep dive into how a metal lathe works and explore the various techniques that operators use to create machine parts, gears, and tools. We’ll also explore the history of the metal lathe and how it has revolutionized the manufacturing process. Whether you’re a veteran operator or have never touched a metal lathe, this blog series will give you a newfound appreciation for this amazing tool.

So, buckle up, and let’s dive into the world of metalworking.

Introduction

If you’re wondering how a metal lathe works, you’re not alone. This powerful tool is used in metalworking to cut and shape metal pieces precisely. At its core, a metal lathe spins a workpiece while a cutting tool moves along it, shaving off material to shape it into the desired final form.

The operator controls the cutting tool’s movement and the speed at which the workpiece rotates, allowing them to create intricate designs and accurate cuts. Metal lathes range in size from small tabletop models to massive industrial machines, but they all work essentially the same way. Whether you’re a metalworking expert or just getting started, understanding how a metal lathe works is essential to creating precise, high-quality metal pieces.

Explanation of Lathe

Introduction: Have you ever wondered how complex cylindrical and conical shapes are produced with such precision? Well, the answer lies in the use of a Lathe. A lathe is a machine tool that rotates a workpiece to perform various operations, such as cutting, drilling, and shaping. They are mainly used in metalworking, woodworking, glassmaking, and other materials.

Lathe machines come in different sizes and designs, from small tabletop versions to large industrial models. Lathe machines have numerous parts, including the bed, which is the base that supports the workpiece and other machine components. The headstock holds the spindle, a rotating part that holds the workpiece.

The carriage is where the cutting tool is mounted and can move back and forth along the bed. The tailstock supports the other end of the workpiece. The cutting tool itself is a crucial component and comes in various types, including turning tools, drilling tools, and boring tools.

In conclusion, the lathe is an essential piece of machinery in the manufacturing industry. It’s versatile and can be used to produce different types of shapes with high precision and accuracy. With the right tools and techniques, a lathe can help produce complex pieces for different industries in both large and small quantities.

Parts of a Metal Lathe

“Have you ever wondered how a metal lathe works? Essentially, a metal lathe is a machine tool used for cutting, drilling, and shaping metal. It consists of several parts that work together to achieve these tasks. The first is the bed, which is the foundation of the lathe and serves as a base for all the other components.

The headstock is another important component that houses the spindle and chuck which hold and rotate the workpiece. The tailstock, on the other hand, supports the other end of the workpiece and can be moved along the bed to adjust the length. The carriage is responsible for moving the cutting tool along the workpiece, enabling the shaping and cutting process.

Finally, there is the cutting tool, which is usually made of high-speed steel and shapes the workpiece using different techniques such as turning, drilling, and facing. Understanding how these parts work together is essential for anyone looking to operate a metal lathe effectively.”

Bed and Ways

A metal lathe is a versatile tool used in metalworking, woodworking, and other industries to cut and shape various materials. It consists of several key components, including the headstock, tailstock, bed, and ways. The bed is the flat, horizontal surface that supports the carriage and other components of the lathe.

The ways are the two parallel rails or tracks that run along the length of the bed, providing smooth and precise movement for the carriage and cutting tools. The headstock houses the motor, gears, and spindle, which rotate the workpiece, while the tailstock supports the other end of the workpiece and can be moved along the ways to adjust the length of the workpiece. Understanding the different parts of a metal lathe is essential for using it effectively and safely in a variety of applications.

So, whether you are a hobbyist or a professional machinist, taking the time to learn about the various components of a metal lathe is a crucial step towards becoming a skilled craftsperson.

Headstock and Gear Train

The headstock and gear train are vital components of a metal lathe. The headstock is located at the left-hand side of the lathe and holds the spindle which rotates the workpiece. It is designed to transmit power from the motor to the spindle.

The gear train, on the other hand, is responsible for changing the rotational speed of the spindle. It is composed of a set of gears that are mounted on a shaft and connected to a lever or knob that allows the operator to adjust the speed. The versatility of a metal lathe depends on the quality and durability of its gear train.

Gear trains of high-end lathes use helical-cut gears, which reduce noise and vibration while increasing precision and reducing wear. A well-designed headstock and gear train allow for a variety of machining operations, resulting in quality workpieces. For example, threading, drilling, and boring can be accomplished with ease and precision with the right configuration of the headstock and gear train.

It is essential to choose a well-known and reliable manufacturer to ensure a metal lathe’s optimal performance.

Tailstock and Carriage

A metal lathe is a versatile machine that can perform a wide variety of turning operations on metal. The tailstock and carriage are two important parts of a lathe that enable it to make precise cuts and shapes. The tailstock is located at the end of the lathe and is used to support the other end of the workpiece while it is being cut.

The carriage, on the other hand, is the part of the lathe that holds the tool and moves it along the length of the workpiece. It is driven by a lead screw, which allows the tool to move with great accuracy. Both the tailstock and carriage are adjustable, allowing the machinist to make precise cuts and achieve the desired shape.

The tailstock can be moved along the bed of the lathe to accommodate different lengths of workpieces, while the carriage can be rotated to make angled cuts. Overall, the tailstock and carriage are integral parts of a metal lathe that enable precision turning operations to be performed with ease and accuracy.

Spindle and Chuck

When it comes to metal lathes, there are a variety of parts that come together to create a functioning machine. One of these key components is the spindle and chuck. The spindle is the rotating axis of the lathe, which holds the workpiece in place.

It is driven by the lathe’s motor and allows for precise and controlled rotation of the material being worked on. The chuck, on the other hand, is the part that holds the material in place. It is attached to the spindle and can be adjusted to fit different shapes and sizes of materials.

The chuck is important because it keeps the material stable during the machining process, allowing for accurate cuts and shaping. Together, the spindle and chuck are essential components of a metal lathe, allowing for precision and control in shaping and cutting materials.

Operations of a Metal Lathe

If you’re curious about how does a metal lathe work, here’s a brief explanation. A metal lathe is a machine that removes material from a piece of metal to shape it into a desired form using cutting tools. The workpiece is mounted onto the chuck, which rotates the metal at high speed while the cutting tool, attached to a carriage, moves along the workpiece to remove the unwanted material.

The operator can adjust the position and angle of the cutting tool to achieve the desired shape. There are different types of metal lathes, including engine lathes and CNC lathes, each with their own unique operations. The precision and flexibility of a metal lathe make it a valuable tool in industries like manufacturing and machining, where creating intricate metal parts is a crucial part of the process.

Whether the task is simple or complex, a metal lathe is a versatile machine that can bring your metalworking creations to life.

Turning

When it comes to machining operations, using a metal lathe is one of the most versatile methods available. One of the key operations that can be performed on a metal lathe is turning, which involves spinning a workpiece while a cutting tool removes material from its surface. This can be used to create cylindrical shapes, tapered pieces, and much more.

To perform turning on a metal lathe, the workpiece is mounted onto the lathe’s chuck, which rotates it at a controlled speed. The cutting tool is then brought into contact with the rotating workpiece, either manually or using a computer-controlled system. The cutting tool is typically made from hard materials such as carbide or high-speed steel, and is designed to remove small amounts of material with each pass.

The operator can adjust the position of the cutting tool relative to the workpiece, which allows for custom shapes and sizes to be created. Some common applications of turning include creating shafts, bolts, and pins. The precision and accuracy of a metal lathe make it a popular choice for machining operations, as it can produce very high-quality items with tight tolerances.

In summary, turning is a crucial operation performed by metal lathes that uses a spinning workpiece and cutting tool to remove material and create custom shapes. By adjusting the position of the cutting tool, a wide variety of parts can be made with a high degree of precision. With the right skill and experience, a metal lathe can be a powerful tool for manufacturers and machinists alike.

Facing

If you’re working with metal, a metal lathe is an essential tool to have in your arsenal. A lathe is a machine that rotates a piece of metal at a high speed and cuts it to a desired shape. The operations of a metal lathe can be a little intimidating at first, but with some practice, you can master them.

To use a lathe, you need to secure your metal piece in the chuck, which is a clamping mechanism that holds the metal while it spins. Next, you need to set your cutting tool in the tool post and adjust it to the right height and angle. From there, you can begin cutting into the metal with precision and control.

One of the most important skills to master when operating a lathe is measuring and calibrating your cuts to ensure accuracy. With practice and a little patience, you can create precise and intricate metal shapes and parts using a metal lathe.

Drilling

Drilling Drilling is an essential operation of a metal lathe. It involves creating a cylindrical hole in the workpiece, which can be done using a drill bit. Drilling can be done by feeding the drill bit into the workpiece, which rotates the bit and removes material to create a hole.

There are various types of drilling operations, including center drilling, drilling, reaming, and boring. Center drilling is the first step in the drilling process, which creates a small indentation in the center of the workpiece to guide the drill bit. Drilling, on the other hand, involves creating a hole of a specific diameter in the workpiece.

Reaming is used to improve the diameter and surface finish of an existing hole, while boring is used to create a larger hole in the workpiece. Different types of drill bits can be used for drilling, depending on the material being drilled and the size and depth of the hole required. Some common types of drill bits include twist drill bits, center drill bits, spot drill bits, and indexable drill bits.

Proper drill selection and programming are essential to ensure accurate and efficient drilling operations.

Safety Measures for Working with a Metal Lathe

A metal lathe is a powerful machine that can precisely cut and shape metal into different shapes and sizes. However, working with this kind of machine is not without risks. To ensure your safety, there are several measures you should follow.

Firstly, always wear appropriate personal protective equipment such as safety glasses, ear protection, and gloves. Secondly, make sure to read the manual and follow the recommended procedures before starting the machine. Thirdly, always keep the work area clean and tidy, and avoid wearing loose clothing or jewelry that could get caught in the machine.

Lastly, never leave the machine running unattended and always switch it off and disconnect it after use. By adhering to these safety measures, you can safely operate a metal lathe and create precise and accurate metalwork. So, if you’re wondering how does a metal lathe work, just remember to prioritize safety first!

Wearing Correct Gear

When it comes to using a metal lathe, there are a few safety precautions that you should keep in mind. Perhaps one of the most important safety measures is wearing the correct gear. This means that before you start working with a metal lathe, you should make sure that you have all of the necessary safety gear, including safety glasses or goggles, a face shield, ear plugs, and sturdy work gloves.

These items will help protect you from flying metal shards, sparks, and other hazards that can cause serious injury. Additionally, it’s important to wear appropriate clothing that won’t get caught in the lathe, such as long-sleeved shirts and pants that fit properly. In short, taking the time to gear up properly before operating a metal lathe is an essential step in keeping yourself safe.

Inspecting the Machine before Use

Metal lathe machines are powerful tools used to create various metal parts. However, it is important to inspect the machine before use to avoid any safety hazards. Firstly, make sure that the power is turned off and the machine is unplugged before checking for any damage, such as cracks or bent parts, which could lead to malfunctions.

Inspect the chuck, tailstock, and carriage to ensure they move easily and that all the accessories are safely secured. Check belts and gears for any signs of wear and tear and lubricate them if necessary. It is also essential to use all recommended safety equipment, including gloves, goggles, and earplugs, to protect the user from debris, noise, and any malfunction that could occur.

By performing these safety measures, you can ensure that working with a metal lathe machine is successful and safe.

Conclusion

In conclusion, a metal lathe is like a magician’s wand for machinists. It takes a raw, rough metal piece and spins it around, cutting, shaping, and transforming it into a precise and beautiful piece of art or machinery. With its various mechanisms, such as the chuck and cross slide, the lathe operates with precision and control, allowing the craftsman to unleash their creativity and skill.

It’s a symphony of rotation, movement, and craftsmanship that only a metal lathe can deliver. So, if you want to turn your metal dreams into reality, grab a lathe and let the magic begin!”

FAQs

What is a metal lathe used for?

A metal lathe is a machine tool used to shape and manipulate metal or other materials with a rotating drive.

How does a metal lathe work?

A metal lathe works by rotating a workpiece against a cutting tool, which removes material from the workpiece to create the desired shape or surface finish.

Can a metal lathe be used for woodworking or other materials?

While metal lathes are designed specifically for metalworking, some models can also be used for woodworking or other materials with proper modifications and attachments.

What are the different types of metal lathes?

The different types of metal lathes include engine lathes, turret lathes, CNC lathes, and Swiss-style lathes.

How do you determine the speed to set a metal lathe?

The speed to set a metal lathe is determined by the type and hardness of the material being worked on, as well as the desired depth and finish of the cut.

What are some safety precautions to take when using a metal lathe?

Safety precautions when using a metal lathe include wearing proper protective equipment, ensuring the workpiece is secure, keeping fingers and clothing away from moving parts, and using the machine only after proper training and instruction.

How do you maintain a metal lathe?

To maintain a metal lathe, you should regularly clean the machine, inspect and replace worn or damaged parts, and lubricate moving components as needed. Additionally, you should store the machine in a dry, clean area to prevent rust and other damage.