Do you know how those large hydraulic jackhammers work? Sure, you’ve seen them demolishing buildings with ease, but have you ever thought about how they can pulverize concrete and hard rocks without breaking a sweat? In this blog post, we will get down to the nitty-gritty details of how these powerful tools operate. From the hydraulic system to the impact mechanism, we’ll explore how these jackhammers deliver forceful blows that break up even the toughest of materials. So, grab your hard hat and let’s dive into the world of hydraulic jackhammers.

Introduction

If you’re wondering how a hydraulic jackhammer works, it’s all about power and pressure. These machines use pressurized hydraulic fluid to generate forceful impacts to break up tough materials like concrete or rock. Essentially, the fluid is pumped into the hammer to create pressure, which is then released through a valve that propels a piston to strike the chisel bit.

This process creates a powerful force that can penetrate even the strongest of surfaces. The hydraulic system is also responsible for controlling the speed and force of the hammer, giving the operator complete control over the tool’s performance. Overall, the combination of fluid pressure, valve control, and precision engineering make hydraulic jackhammers the go-to tool for serious demolition work.

Explanation of hydraulic jackhammers

Hydraulic jackhammers are powerful tools that work by harnessing the power of hydraulics. They are commonly used to break up concrete, asphalt, and rock, and can be found on construction sites all over the world. At their core, hydraulic jackhammers consist of two main components: a hydraulic power unit and a hammer.

The power unit uses hydraulic fluid to generate a high-pressure flow of oil, which is then directed to the hammer. Once the oil reaches the hammer, it is converted into mechanical force, which is used to drive a piston up and down inside the hammer. This motion causes the tip of the hammer to strike the surface being worked on, creating powerful bursts of force that are capable of breaking even the toughest materials.

Overall, hydraulic jackhammers are a vital tool for any construction site, providing workers with the power they need to tackle even the most demanding projects.

Brief history of hydraulic jackhammers

Hydraulic jackhammers have a rich history extending back over 150 years. Early versions of these powerful machines were originally used in mining and quarrying to break up rock and extract valuable minerals. In the late 19th century, a German engineer named Friedrich Krupp developed a compressed-air jackhammer, which was popularized as a more efficient alternative to manual labor.

However, the technology was limited by the distance it could be used from the air compressor, leading to the invention of hydraulic jackhammers in the early 20th century. These machines used pressurized fluid to power the piston, making them more portable and ideal for use in the construction and demolition industries. Today, hydraulic jackhammers have become ubiquitous tools on construction sites, used to break up concrete, asphalt, and other tough materials.

The hydraulic system is not only more efficient but also quieter and more environmentally friendly, making it the go-to choice for modern construction projects.

Components of Hydraulic Jackhammers

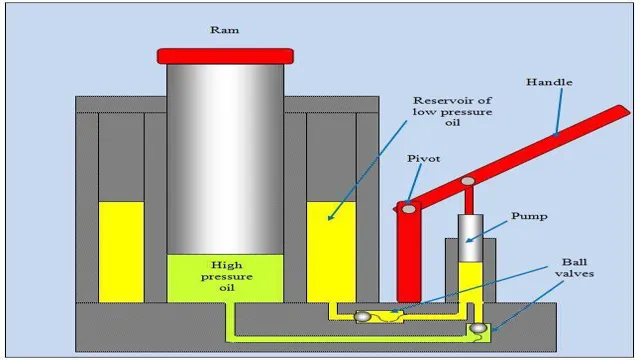

If you’ve ever seen a hydraulic jackhammer in action, you may have wondered how such a powerful tool works. The secret behind a hydraulic jackhammer’s power lies in its two main components: the power unit and the hammer. The power unit is typically powered by an external engine or electric motor and consists of a hydraulic pump, which pressurizes hydraulic fluid, and a hydraulic cylinder, which receives the pressurized fluid and converts it into mechanical force.

This force is then directed towards the hammer, which is attached to the end of the cylinder. When the pressurized fluid reaches the hammer, it drives a piston inside the hammer forward, which in turn strikes a chisel or point. This striking action creates shock waves that break apart the material being worked on.

With each strike, the material is broken into smaller and smaller pieces until it is small enough to be removed manually. It’s this repeated striking action that makes a hydraulic jackhammer such an effective tool for breaking through tough materials, like concrete or asphalt.

Cylinder

A critical component of hydraulic jackhammers is the cylinder. The cylinder is responsible for converting the hydraulic fluid’s pressure into mechanical force that powers the jackhammer’s internal piston, which, in turn, drives the tool’s chisel or point. In essence, the cylinder is the heart of the hydraulic jackhammer, making it a durable and highly effective tool for demolition, excavation, and other demanding applications.

Typically, the cylinder is made of high-strength alloy steel or other durable metal, ensuring that it can withstand the extreme pressure and vibrations generated by the jackhammer’s operation. Without a robust cylinder, the hydraulic jackhammer’s overall performance would suffer, making it less efficient and less effective. Therefore, proper maintenance of the cylinder is essential to keep the hydraulic jackhammer operating at peak performance.

Valve

Valve Hydraulic jackhammers are powerful tools that are commonly used in construction projects for breaking up concrete, asphalt and other hard surfaces. The hydraulic jackhammer mainly contains three components: the cylinder, the piston, and the valve. The valve plays an integral part in the functionality of the hydraulic jackhammer.

It is responsible for controlling the flow of oil and determining the power output of the jackhammer. The valve directs the flow of oil into the cylinder, causing the piston to move rapidly back and forth. This rapid movement creates the hammering action that is necessary for breaking up concrete or asphalt.

Therefore, the valve is an important component that determines the power of the jackhammer, making it possible to accomplish difficult tasks in a shorter amount of time. Without the valve, the hydraulic jackhammer would not be able to function efficiently. In conclusion, the valve is a crucial part of hydraulic jackhammers and its design and function are essential for peaceful and successful construction projects.

Piston

Piston When it comes to hydraulic jackhammers, the piston is an essential component that plays a crucial role in the operation of the tool. Essentially, the piston is a cylindrical device that moves back and forth inside the jackhammer’s cylinder, creating the force necessary to deliver the impact required to break through tough materials. It is responsible for compressing the hydraulic fluid, which in turn powers the hammer’s chisel.

When the fluid is forced against the chisel, the piston’s movement creates the powerful blows needed to break through concrete or rock. Essentially, the piston is the engine of the jackhammer, converting the hydraulic energy into mechanical force. Without it, the jackhammer would be useless.

So, if you’re ever in need of a jackhammer, make sure to appreciate the humble yet powerful piston that makes it all possible.

Bit

Bit Before discussing the components of hydraulic jackhammers, it’s important to understand the role of the bit. This is the part of the jackhammer that makes contact with the surface being broken up. The bit is composed of high-strength steel and is designed to withstand the high levels of pressure and force needed for breaking up hard surfaces.

Jackhammer bits come in a variety of shapes and sizes, with each type suited to specific applications. For example, a chisel bit is used for breaking up concrete while a point bit is better suited for breaking up rocks and hard soil. Choosing the right type of bit is essential for maximizing the efficiency and effectiveness of a hydraulic jackhammer.

Additionally, regular maintenance and inspection of the bit can help ensure its longevity and prevent costly replacements.

Operation of Hydraulic Jackhammers

Hydraulic jackhammers are powerful tools utilized in demolition works. But have you ever wondered how these machines work? Hydraulic jackhammers operate by converting hydraulic power into kinetic energy. The jackhammer is powered by a hydraulic system, which is composed of oil or fluid, a reservoir, a pump, a motor, and a valve.

When the operator pulls the trigger, oil is pumped into a cylinder, creating pressure. The pressure builds up until it exceeds the resistance of the material that the jackhammer is hitting. This pressure then forces the chisel or bit in the jackhammer to oscillate back and forth at a high velocity, creating the hammering action that breaks up the material.

The hydraulic fluid that powers the jackhammer also helps to cool the system and lubricate the moving parts to reduce wear and tear. Hydraulic jackhammers are highly effective machines used in various applications, from demolition to excavation, and offer a more efficient and less labor-intensive alternative to traditional hand tools.

Step-by-step guide on using a hydraulic jackhammer

Operating a hydraulic jackhammer may seem like a challenging task, but it is pretty straightforward if you know the correct steps. First, assemble all the required equipment, including the jackhammer, hoses, and power pack. Connect the hoses and ensure that the jackhammer’s working pressure is optimal.

Secondly, make sure that the jackhammer is firmly positioned on the surface you intend to break up. The next step is to turn on the power pack, and you are ready to begin breaking up concrete or rocks. Use the jackhammer by holding it perpendicular to the surface and maintain a steady grip.

Gradually move the jackhammer back and forth to allow it to chip away at the surface. Ensure that you have taken adequate safety measures such as wearing protective gear, earplugs, and safety glasses. In summary, with the appropriate tools and inherent safety precautions, operating a hydraulic jackhammer is a task that you can execute successfully and efficiently.

How pressure is produced in hydraulic jackhammers

Hydraulic jackhammers are powerful tools that are used to break up concrete, asphalt, and other hard surfaces. These highly efficient machines use hydraulic pressure to generate enough force to break through even the toughest materials. The hydraulic system consists of a pump that pushes hydraulic fluid into a hydraulic cylinder, which then pushes a piston that moves the jackhammer’s chisel.

The piston moves back and forth at high speeds, creating impact force that breaks up the surface being worked on. The hydraulic system creates pressure by forcing the hydraulic fluid through small openings in the cylinder, creating a high-pressure zone. The pressure created by the hydraulic system is what allows the jackhammer to deliver such a powerful blow, and it is one of the key reasons why hydraulic jackhammers are so effective.

In addition to their power, hydraulic jackhammers are also known for their reliability, durability, and ease of use, making them a popular choice for construction and demolition projects.

Advantages of Hydraulic Jackhammers

A hydraulic jackhammer is a powerful tool used in construction projects to break through concrete, rocks and other tough materials with ease. But how does a hydraulic jackhammer work? At its core, the jackhammer uses hydraulic pressure to generate the necessary force for breaking through solid objects. It works by using a pump to direct the flow of pressurized hydraulic fluid into a cylinder.

This hydraulic fluid then moves a piston that strikes the chisel attached to the tool. The piston moves back and forth at an incredible speed, delivering a powerful blow to the surface being worked on. Compared to other types of jackhammers, hydraulic jackhammers have several distinct advantages.

For instance, they produce less noise and vibration, making them comfortable to use for extended periods of time. Additionally, they are more efficient and require less maintenance than other types of jackhammers. Furthermore, hydraulic jackhammers deliver higher levels of accuracy and precision, making them the go-to option for projects with strict requirements.

High power output

If you’re on the lookout for a powerful tool to help break through concrete, pavement or other hard surfaces, then a hydraulic jackhammer is the perfect tool for you. One of the main advantages of these machines is the high power output they offer. They can generate enough power to break through even the most stubborn materials, making them an ideal option for those in the construction or demolition industry.

With a hydraulic jackhammer, you can tackle tough jobs quickly and efficiently, with less effort spent on your part. Plus, they’re designed to be durable and long-lasting, which means that you won’t have to worry about needing to replace them any time soon. So if you want to get the job done right the first time, consider investing in a hydraulic jackhammer for your next project.

Efficient and reliable

Hydraulic jackhammers are a popular choice in the world of construction for several reasons. One of the major advantages of hydraulic jackhammers is their efficiency. Because they rely on hydraulic power, they are able to deliver more force with less effort than pneumatic or electric jackhammers.

This means that workers can get more done in less time, without sacrificing the quality of their work. Additionally, hydraulic jackhammers are highly reliable. They are built to withstand heavy use, and they are less prone to overheating or other mechanical failures than other types of jackhammers.

This reliability means fewer delays and less downtime for repairs, which can ultimately save construction companies time and money. Overall, the efficiency and reliability of hydraulic jackhammers make them a top choice for many construction professionals.

Easy to operate

One of the greatest advantages of hydraulic jackhammers is how easy they are to operate. Unlike their pneumatic counterparts, hydraulic jackhammers require very little maintenance and don’t need an air compressor to work. Instead, they use hydraulic fluid to power the hammering action, which means they are much quieter and produce no exhaust fumes.

Additionally, because they have fewer moving parts, they are generally more reliable and last longer. You don’t need to be a professional to use a hydraulic jackhammer either. Many models come with adjustable speed settings, and the controls are user-friendly.

The best part is that hydraulic jackhammers are incredibly efficient, making short work of even the toughest materials like concrete and asphalt. Whether you are a DIY enthusiast or a professional contractor, a hydraulic jackhammer is an excellent investment that will save you time and effort on your projects.

Conclusion

In conclusion, a hydraulic jackhammer is like a superhero disguised as a construction tool. It uses hydraulic power to produce rapid and powerful blows that can break through even the strongest of materials. Just like how a superhero’s strength comes from within, the hydraulic power of a jackhammer comes from pressurized fluid that creates a forceful impact.

So the next time you pass by a construction site and hear the rhythmic pounding of a jackhammer, remember that it is not just a tool, but a true superhero in action.”

FAQs

What is a hydraulic jackhammer?

A hydraulic jackhammer is a high-pressure tool that uses hydraulic power to break through tough materials like concrete and asphalt.

How does a hydraulic jackhammer work?

A hydraulic jackhammer works by using hydraulic pressure to create powerful percussive blows that break apart the material it’s working on.

What are the main components of a hydraulic jackhammer?

The main components of a hydraulic jackhammer include a hydraulic cylinder, piston, valve, and hammer.

What are the advantages of using a hydraulic jackhammer compared to other types of jackhammers?

Hydraulic jackhammers are more powerful and efficient than other types of jackhammers, making them ideal for heavy-duty tasks like demolition and excavation.

What types of jobs are hydraulic jackhammers typically used for?

Hydraulic jackhammers are commonly used in construction and demolition projects, for breaking through concrete, asphalt, and other tough materials.

How do you maintain a hydraulic jackhammer?

To maintain a hydraulic jackhammer, you should regularly check and replace the oil and filters, inspect the hoses and fittings for leaks, and keep the tool clean and lubricated.

What should you wear when operating a hydraulic jackhammer?

When operating a hydraulic jackhammer, you should wear eye and ear protection, gloves, a hard hat, and sturdy work boots to protect yourself from flying debris and noise.