How Does a Cordless Drill Brake Work? A Comprehensive Guide

Cordless drills are a convenient tool for DIY enthusiasts and professionals alike. These drills are equipped with high-power motors and can be used for a wide range of tasks, from drilling holes to screwing in bolts. One important feature of cordless drills that is often overlooked, however, is the braking system.

The braking system in a cordless drill is responsible for stopping the drill bit from spinning as soon as you release the trigger. This safety feature ensures that you have full control over the tool and prevents accidents. In this blog post, we will take a closer look at how cordless drill brakes work and why they are an essential component of any cordless drill.

So buckle up, grab your tool belt, and let’s get started!

Introduction

Cordless drills have become an essential tool in every household and construction site. A cordless drill brake is an important safety feature that comes into play when you release the trigger or when the battery dies in the middle of use. When the trigger is released or the battery dies, an electromagnetic brake kicks in, causing a magnetic field that stops the rotation of the drill.

The magnetic field resists the spinning of the motor, thus stopping the drill bit immediately. This safety feature prevents the drill from spinning uncontrollably and causing potential danger to the user or bystanders. So, now you know how the cordless drill brake works and why it is an indispensable safety feature to take into consideration when buying a new cordless drill.

Overview of Cordless Drill Brakes

Cordless drill brakes are an essential safety feature in power tools. They allow users to stop the drill quickly in case of an emergency. These brakes function by using an electric motor to oppose the drill’s spinning motion, causing it to stop.

This feature is particularly useful in situations where the user might accidentally drop or lose control of the drill. In such cases, the cordless drill brake will take over immediately, keeping the user safe from harm. Having a drill with a brake system can offer peace of mind to both professional contractors and DIY enthusiasts alike.

It ensures that the tool is not only useful but also safe to operate, making it an excellent investment for anyone looking to purchase a new cordless drill.

Importance of Cordless Drill Brakes

Cordless drill brakes are an essential component of any drill. Without them, the drill can spin out of control, posing a serious safety hazard. These brakes are located near the chuck, and they work by stopping the drill’s rotation when the trigger is released.

This ensures that the drill stops quickly and doesn’t continue to spin, even after the user has released the trigger. Having a cordless drill with a brake mechanism is especially important for those who are new to using power tools. The brake system can help prevent accidents and protect both the user and their workpiece.

So, if you’re in the market for a cordless drill, make sure it has a brake mechanism built-in to ensure safety and ease of use.

How Cordless Drill Brakes Work

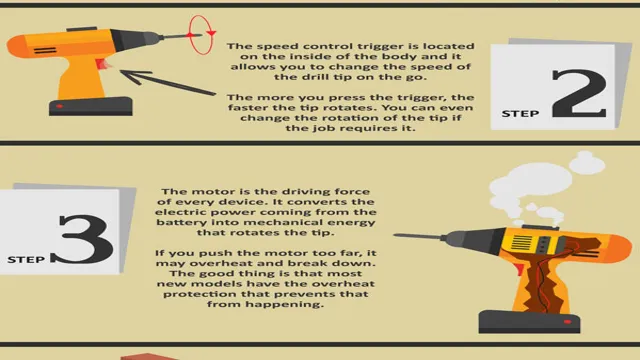

If you’ve ever wondered how a cordless drill brake works, you’re not alone! When you release the trigger on a cordless drill, it’s designed to stop spinning within a fraction of a second. This is where the brake comes in. The way a cordless drill brake works is by using an electromagnetic brake system that holds the drill chuck in place when it’s not in use.

When you release the trigger, the motor is automatically disconnected from the chuck, and the brake is engaged, causing the chuck to stop spinning. It’s an essential safety feature that prevents unnecessary accidents and damage to the tool. When shopping for a cordless drill, it’s important to look for models with reliable brakes to ensure your safety while using the tool.

Overall, the cordless drill brake is a simple yet effective mechanism that provides an added layer of protection during use.

Mechanism of Cordless Drill Brakes

Cordless drill brakes are an essential safety feature that allows the user to stop the drill quickly in case of an emergency. The mechanism behind cordless drill brakes works by applying an electric current to the motor’s armature and creating resistance, which slows down the spinning of the drill bit. This resistance is created by the interaction between the magnetic fields generated by the permanent magnets and the electric current flowing through the armature.

You May Also Love:

The brake is activated through a switch that interrupts the current flow, causing the motor to slow down rapidly. This helps prevent injuries and damage to the workpiece or drill bit. It’s important to remember that even with the brake, one should always wear proper safety equipment such as eye protection and gloves when using a cordless drill.

Components of Cordless Drill Brakes

Cordless drill brakes are critical components that ensure safety and precision when working with tools. The brake is designed to quickly stop the drill after releasing the trigger, preventing the drill from spinning out of control and causing injuries or damage. So, how do cordless drill brakes work? Most cordless drills use an electronic motor brake that quickly stops the drill’s rotation by reversing the current flow in the motor.

This process generates a magnetic field that slows down and stops the motor’s movement. Additionally, some advanced cordless drills come with mechanical brakes that clamp down on the drill bit and stop the movement. The combination of these two brakes ensures maximum safety and precision when using the cordless drill, making it an indispensable tool for DIYers, contractors, and professionals.

Operation of Cordless Drill Brakes

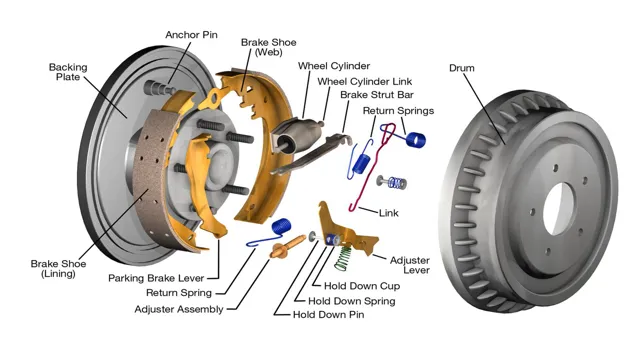

Cordless drill brakes are a crucial safety feature that ensures your drill operates safely and securely. So, how do they work? Cordless drill brakes come in two types: electromagnetic and mechanical. Electromagnetic brakes are the most common and use a magnetic field to stop the drill’s motion.

When you release the trigger, the magnetic field kicks in, pulling the brake’s brake drum toward the motor, creating friction and stopping the drill. Mechanical brakes use the same principle, but they use a spring instead of a magnet. When you release the trigger, the spring expands and pushes against the brake drum, creating friction and stopping the drill.

Regardless of the type, cordless drill brakes provide dependable and useful safety features for professionals and do-it-yourselfers who value protection and accuracy. Next time you’re drilling, pay attention to how your cordless drill’s brakes work to ensure you’re operating safely.

Types of Cordless Drill Brakes

If you’re wondering how a cordless drill brake works, you’ll be pleased to know that there are several types. One common type is the electric brake, which uses an electric current to quickly stop the drill’s rotation when the trigger is released. This type of brake is ideal for precision work as it allows you to maintain control over the tool both when in use and when you stop drilling.

Another type of brake is the mechanical brake, which consists of a disc or drum that stops the drill bit from rotating when pressure is applied. The mechanical brake is highly reliable and works even if there is a power failure. Some high-end cordless drills also come equipped with a dynamic brake that uses a software program to control the drill’s motor and brake functions.

This type of brake is beneficial for reducing the wear and tear on the motor as well as extending the battery life. Regardless of the brake type, knowing how it works will help you use your cordless drill more efficiently and safely.

Direct Drive Brakes

Direct Drive Brakes When it comes to cordless drill brakes, direct drive brakes are one of the most common and efficient types available. These brakes work by exerting pressure directly on the motor’s armature, which effectively stops the drill’s rotation. Direct drive brakes are highly responsive, providing immediate stopping power and minimizing incidents of kickback and accidents.

Unlike other types of brakes that rely on friction to slow down a drill, direct drive brakes are powered directly by an electrical current. This makes them incredibly efficient and reliable, ensuring that your drill comes to a complete stop in mere seconds. Overall, if you want a cordless drill that’s safe and easy to use, direct drive brakes are definitely worth considering.

Friction Brakes

Friction Brakes When it comes to cordless drills, a good brake mechanism is essential for precision and safety. There are two main types of cordless drill brakes: mechanical and electronic. Mechanical brakes, also known as friction brakes, work by applying pressure to the spinning rotor, slowing down the drill and bringing it to a stop.

They are reliable and affordable, but can wear out over time and may require maintenance. Electronic brakes, on the other hand, use a motor control system to instantly stop the drill when the trigger is released. They are more expensive, but offer faster stopping times and longer lifespan.

Ultimately, the type of brake you choose will depend on your specific needs and preferences. If you prioritize affordability and don’t mind the occasional maintenance, a mechanical brake may be the way to go. But if precision and fast stopping times are a top priority, an electronic brake may be the better option.

Regenerative Brakes

Regenerative brakes are a feature that’s increasingly seen in cordless drills. These types of brakes work by converting the momentum of the drill’s rotational energy into electricity during braking. This process helps to slow down or stop the drill quickly, making them ideal for heavy-duty applications where precision and control are crucial.

There are two main types of cordless drill brakes- electric brakes and mechanical brakes. Electric brakes work by applying electrical current to the motor, which in turn slows down the drill bit. Mechanical brakes, on the other hand, work by using a physical braking mechanism to slow down the drill’s rotation.

Whether you favor electric or mechanical brakes, incorporating regenerative braking technology into your cordless drill can offer power, control and reliability, ultimately enhancing your drilling experience.

Conclusion

In summary, a cordless drill brake works by utilizing a clutch that disengages the drill’s motor when a certain amount of torque is reached, preventing overdriving and potential damage to the drill or workpiece. It’s like having a miniature traffic cop inside your drill, signaling when it’s time to slow down and avoid a collision. So go ahead and drill with confidence, knowing that your cordless drill brake has got your back (and your bits)!

Benefits of Cordless Drill Brakes

Cordless drill brakes can provide numerous benefits for both professionals and DIY enthusiasts. These brakes can help prevent the drill from twisting out of control when you remove the bit from the workpiece, which can lead to dangerous accidents. In addition, cordless drill brakes can help prolong the life of your tool by reducing its wear and tear, resulting in long-lasting performance.

There are two types of cordless drill brakes: mechanical and electronic. Mechanical brakes use a set of clutches to stop the drill’s rotation while electronic brakes use a sensor to stop the motor. Mechanical brakes are more affordable and less complicated, but electronic brakes can offer faster stopping times and are more efficient at protecting the user from accidents.

Overall, incorporating cordless drill brakes into your toolbox can improve your safety and help you work more efficiently. So what are you waiting for? Get your hands on one today and take your drilling game to the next level!

Considerations when Purchasing a Cordless Drill with Brakes

When looking to purchase a cordless drill with brakes, it is important to consider the different types of brakes available. One of the most common types is a mechanical brake, which works by stopping the movement of the chuck when the trigger is released. This provides immediate stopping power and can be useful for precision work.

Another type of brake is an electronic brake, which uses a sensor to detect when the trigger has been released and stops the motor almost immediately. This can be helpful for safety reasons and allows for a quicker transition between tasks. Additionally, there are drills that come equipped with both mechanical and electronic brakes, providing the benefits of each type.

By understanding the different types of brakes available, you can choose the one that best suits your needs and ensures a safe and effective work environment.

FAQs

1. How Does a Cordless Drill Brake Work? A: A cordless drill brake works by utilizing an electromagnetic brake that clamps down on the motor shaft to stop it from spinning when the trigger is released. 2. Is It Safe to Use a Cordless Drill Without a Brake? A: No, it is not safe to use a cordless drill without a brake. The brake helps to prevent injuries by stopping the drill from spinning unexpectedly. 3. How Do I Check if My Cordless Drill Brake is Working Properly? A: To check if your cordless drill brake is working properly, turn the drill on and then release the trigger. The drill should stop spinning almost immediately. If it continues to spin, the brake may need to be repaired or replaced. 4. Can I Adjust the Sensitivity of My Cordless Drill Brake? A: Some cordless drills may have adjustable brake sensitivity. Check your user manual or contact the manufacturer to see if this is an option for your specific drill. 5. What Happens if the Brake Fails on My Cordless Drill? A: If the brake fails on your cordless drill, it can be extremely dangerous as the drill may continue to spin even when the trigger is released. It is important to have the brake repaired or replaced as soon as possible. 6. Can I Replace the Brake on My Cordless Drill Myself? A: It is not recommended to try to replace the brake on your cordless drill yourself as it can be a complicated process that requires specialized knowledge and tools. It is best to take your drill to a professional for repairs. 7. How Often Should I Have My Cordless Drill Brake Inspected? A: It is recommended to have your cordless drill brake inspected and serviced at least once a year or more often if you use it frequently or in high-risk environments. This can help prevent accidents and prolong the lifespan of your drill.