If you’re an avid car enthusiast, then you know the importance of having reliable equipment to keep your car in top shape. A compression tester is an essential tool that every car owner should have in their toolbox. But how does it work? In a nutshell, a compression tester measures the amount of pressure inside each cylinder of your vehicle’s engine.

This pressure is a vital aspect of engine performance and can reveal underlying problems such as worn piston rings, leaky valves, or a blown head gasket. In this article, we’ll delve deeper into how a compression tester works and why it’s a crucial tool for maintaining your car’s health.

Overview

Have you ever wondered how a compression tester actually works? Well, a compression tester is a specialized tool that measures the amount of pressure produced by the engine’s combustion process. It does this by connecting to the spark plug hole and using the starter motor to crank the engine while measuring the pressure produced. The reading obtained from the compression tester can then be used to determine the health of the engine’s piston rings, cylinder walls, and valves.

Generally, a compression test is performed when diagnosing engine problems such as rough idling, misfires, and reduced power output. The compression tester is a valuable diagnostic tool that can save you a lot of money by determining the root cause of engine problems and preventing further damage. In summary, a compression tester is simple yet effective, and understanding how it works can help you take better care of your engine.

Understanding Compression

Compression is a vital tool in today’s digital world, allowing us to store and transmit large volumes of data with minimal overheads. At its core, compression works by removing redundancies in data, thereby reducing its size. There are two primary types of compression: lossless and lossy.

Lossless compression maintains all the original data, making it ideal for text files and other critical data. In contrast, lossy compression reduces the overall quality of data, making it more suitable for media files, where some loss of quality is considered acceptable. Ultimately, while compression does come with some trade-offs, such as added processing time, its benefits are hard to ignore, making it an integral part of modern digital life.

What is a Compression Tester?

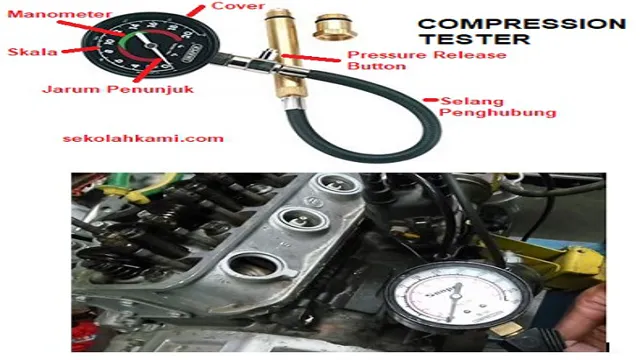

Compression tester is a tool used for analyzing the engine’s compression to determine its health and performance. This device is used both in professional and DIY workshops to measure the strength of the engine’s cylinders. A compression tester comprises two primary components: a gauge to measure the cylinder’s compression pressure and an adapter that fits over the spark plug hole.

The compression tester is easy to use; you need to remove the spark plug, screw in the adapter, and attach the gauge. By cranking the engine a few times, you will obtain the compression reading, which you can use to conclude if there are any problems. Whether you want to perform routine engine maintenance or diagnose specific problems, a compression tester is a must-have tool.

It is an inexpensive and straightforward tool that can save you significant time and money down the road.

Using a Compression Tester

If you’re wondering how a compression tester works, you’re not alone. Essentially, a compression tester is a tool that measures the pressure on each cylinder of a car’s engine. This pressure reveals the engine’s ability to compress air and fuel, and ultimately ignite it.

A compression tester works by first removing the spark plug from each cylinder, then screwing the gauge into the spark plug hole. Next, the engine is cranked a few times using the starter motor, and the maximum pressure reading is recorded. This reading is then compared to the manufacturer’s recommended pressure range to determine if the engine is functioning properly.

A compression tester is a valuable tool for any mechanic or car owner, as it can quickly diagnose problems with an engine’s performance and help prevent costly repairs down the road. So, next time you’re experiencing engine problems, give a compression tester a try to help you pinpoint the issue.

Pre-Test Preparations

When it comes to performing a compression test on an engine, preparation is key to obtaining accurate results. One of the crucial tools to use in this process is a compression tester. Before beginning the actual test, it’s important to make sure that the engine is warmed up to its normal operating temperature and that all of the spark plugs have been removed.

Next, the compression gauge should be attached to the first cylinder and the throttle should be opened fully to allow in as much air as possible. The engine should then be cranked for a few seconds until the gauge stops increasing, at which point the reading should be recorded. This process should be repeated for each additional cylinder, making sure to label each reading for reference.

By properly utilizing a compression tester and following these pre-test preparations, you’ll be able to accurately diagnose any issues with your engine’s compression.

Connecting the Tester

When it comes to testing your vehicle’s compression, using a compression tester is crucial. But before you can start testing, you need to connect the tester to your engine properly. Start by locating the spark plugs, which are usually on the top of the engine.

Remove one of the plugs and attach the compression tester to the now open hole. Make sure the tester is securely connected to the engine and that all connections and seals are tight. Once you’ve properly connected the tester, you’re ready to start testing.

Remember to follow the instructions that come with your specific compression tester to ensure accurate readings. By following these steps and properly connecting your compression tester, you can diagnose any issues with your engine’s compression and keep your vehicle running smoothly.

Reading the Results

When it comes to testing the compression of an engine, using a compression tester can provide valuable information about the health of the engine. To use a compression tester, first remove all of the spark plugs from the engine. Next, insert the compression tester into one of the spark plug holes and crank the engine over a few times.

The compression gauge will show the amount of pressure in the cylinder, which should be consistent across all cylinders. Low readings may indicate worn piston rings or valves, while uneven readings may indicate a blown head gasket. It’s important to carefully read and interpret the results to diagnose any issues in the engine.

By using a compression tester correctly, car owners can ensure their car’s engine is running smoothly and avoid costly repairs down the road. Keyword: compression tester.

Interpreting the Results

If you’re wondering how a compression tester works, it’s actually very simple. This tool measures the amount of pressure that builds up inside your engine’s cylinders when it’s running. The compression tester consists of a gauge that reads this pressure and a hose that’s screwed into the spark plug hole of each cylinder.

When the engine is turned over, the pressure from the pistons is forced into the hose, which is then measured by the gauge. By analyzing the pressure readings, you can get a sense of how well your engine is functioning. A low reading on the compression tester indicates that there may be an issue with the engine’s internal components, such as worn pistons, piston rings, or valves.

High readings may suggest that there is carbon buildup on the valves or spark plugs that need to be cleaned. The information provided by a compression tester can help you diagnose a wide range of potential issues with your engine, allowing you to take corrective action before any major damage occurs.

Normal Compression Levels

When it comes to measuring normal compression levels, understanding the results can be quite complex. The compression level refers to the amount of data reduced during compression as compared to the original size. Data compression is essential to reduce file size and improve data transmission efficiency.

In most cases, normal compression levels range from 60% to 80%, but the ideal level depends on the type of data being compressed. Interpreting the results can be challenging, especially for those not familiar with the technicalities of compression. However, by using the right tools and techniques, it is possible to gauge the effectiveness of compression and make informed decisions.

The key is to use compression algorithms that minimize data loss and maintain data integrity. Investing in quality compression tools can ensure that your data remains safe, secure and easy to manage.

Low Compression Levels and What They Mean

Low compression levels in your car’s engine can be a bit worrisome, but it’s not always a sign of major issues. First, let’s break down what compression levels are and how they work. Basically, compression levels refer to the amount of pressure that builds up inside the combustion chamber of your engine during each cycle.

This pressure is created by the upward movement of the piston compressing the air and fuel mixture before ignition. Ideally, your engine should have steady compression levels across all cylinders. Low compression levels can indicate a number of issues, such as worn piston rings, faulty valves, or a blown head gasket.

However, it can also be a simple fix, such as replacing spark plugs or a damaged timing belt. It’s important to get a thorough diagnostic from a professional mechanic to determine the root cause of the low compression levels. Ignoring the issue can lead to poor engine performance, decreased fuel efficiency, and even engine failure.

So, don’t hesitate to have your engine inspected at the first sign of low compression. Taking care of the issue early on could save you a lot of stress, time, and money down the road.

Final Thoughts

So, you’re wondering how a compression tester works? Well, I’m glad you asked! A compression tester is a tool used to measure the pressure that an engine can produce. It’s a pretty simple tool, really. You just screw the compression tester into the spark plug hole of the engine and crank the engine over a few times.

The compression tester measures the pressure that the engine produces during each crank. This pressure reading can give you an idea of how well the engine is running. If the pressure is too low, it could mean that the engine has a problem with its valves, pistons, or cylinders.

If the pressure is too high, it could mean that the engine is about to detonate and cause damage. Overall, a compression tester is a valuable tool for diagnosing engine problems and ensuring that your engine is running properly. So, next time you’re working on your car or truck, give it a try and see what the pressure reading is.

You might learn something new about your engine!

Conclusion

In summary, a compression tester is like a personal trainer for your engine. It applies pressure to each cylinder, measuring how much force it can generate to keep things running smoothly. Think of it as the ultimate test of strength for your car.

So, next time your car is showing signs of weakness, hook up a compression tester and get to the bottom of the issue before it turns into a full-blown breakdown. Trust us, your engine will thank you later.”

FAQs

What is a compression tester and why is it used?

A compression tester is a tool used to measure the compression pressure of an engine cylinder. It is used to diagnose engine problems, such as worn piston rings or valves, that can cause low compression and affect engine performance.

How does a compression tester work?

A compression tester works by screwing into the spark plug hole of a cylinder and pressurizing it with air or hydraulic fluid. The gauge on the tester measures the pressure of the cylinder, which is compared to manufacturer specifications to determine if the engine is running properly.

What is the normal compression range for a healthy engine?

The normal compression range for a healthy engine is usually between 125 and 180 psi (pounds per square inch). However, this may vary depending on the make and model of the engine.

How can a compression test help diagnose engine problems?

A compression test can help diagnose engine problems by identifying cylinders with low compression pressure, which may indicate problems such as worn piston rings or valves, head gasket failure, or engine timing issues.

Can a compression test be performed on any engine?

Generally, a compression test can be performed on any engine with spark plugs. However, some engines may require special adapters to fit properly, and certain engine designs, such as those with overhead camshafts, may require additional steps or equipment.

How often should a compression test be performed?

A compression test is typically recommended during routine engine maintenance or when engine problems are suspected. The frequency of testing may vary depending on the age and condition of the engine.

Can a home mechanic perform a compression test on their own?

Yes, a compression test can be performed by a home mechanic with basic automotive knowledge and the necessary tools. However, it is important to follow proper safety procedures and manufacturer guidelines when performing any engine work.