How does a Bench Drill Press Work: A Comprehensive Guide to its Mechanics and Usage

Have you ever ventured into the world of woodworking or metalworking and wished for a tool that could make your job easier, faster, and more precise? Look no further than a bench drill press. This versatile machine can drill through materials with ease, create precise holes of varying sizes, and even sand and polish surfaces. But how does it work? At its core, a bench drill press consists of a rotating vertical spindle powered by an electric motor.

The spindle is located in the center of a fixed base and can be raised or lowered using a lever or wheel. A drill chuck is attached to the spindle and holds the drill bit securely in place. The table, which is mounted on the base, can be adjusted both vertically and horizontally to accommodate different sized workpieces.

When the machine is turned on, the spindle begins to rotate, and the user can use the lever or wheel to lower the drill bit onto the workpiece, starting the drilling process. The user can control the speed of the spindle, which depends on the material being drilled and the size of the bit used. This allows for precise control and prevents damage to the material or the drill bit.

In summary, the bench drill press is a powerful and essential tool for any woodworkers or metalworkers. By providing precise control, variable speed options, and adjustable table placement, this machine allows the user to complete a wide range of tasks quickly and efficiently. So why not give it a try and see how it can help enhance your projects?

Overview

If you have ever wondered how a bench drill press works, it’s quite simple. This type of drill press is designed to bore holes through a variety of materials with precision and accuracy. The drill press consists of a sturdy base, a column that holds the drill head, and a drill bit that rotates at high speed to bore through the material.

When the drill press is turned on, the user can adjust the speed and depth of the drill, as well as the angle of the drill bit, to achieve the desired results. The user can also clamp the material to the drill press table for added stability and accuracy. The bench drill press is a versatile tool that can be used in woodworking, metalworking, and other industries that require precise drilling.

Overall, it’s a simple yet incredibly effective tool that can make any drilling task easier and more efficient.

Key Components

When it comes to creating a successful blog, there are a few key components that you should keep in mind. These include having a clear purpose or niche for your blog, creating high-quality content that engages your audience, incorporating multimedia elements like videos and images, optimizing your content for search engines, and promoting your blog through social media and other channels. Each of these components plays an important role in the success of your blog, and it’s important to give each one careful consideration as you plan and create your content.

With the right approach and a bit of effort, you can build a blog that engages and inspires your audience, and that helps you achieve your goals. So why wait? Start creating your own successful blog today!

Types of Bench Drill Presses

Bench drill presses are an essential tool for those who need to bore precise holes in a variety of materials. There are several types of bench drill presses available, each suited for different tasks and applications. Some of the most common types include the drill press, the combination machine, and the radial drill press.

Each has its own unique features and benefits, making it important to choose the right one for your needs. For instance, drill presses are typically the most basic type of bench press, while combination machines offer additional capabilities such as sanding and routing. Radial drill presses, on the other hand, are best suited for large-scale projects and are often used in industrial applications.

No matter which type of bench drill press you choose, it’s important to make sure it is well-maintained and properly aligned to ensure accurate drilling. With the right bench drill press, you can tackle even the most challenging drilling tasks and achieve professional-grade results.

Setting up the Bench Drill Press

If you’re curious about how a bench drill press works, you’re in the right place. Bench drill presses are tools that can make precise holes through metal, wood, and other materials. Setting one up can be a little bit tricky, but it’s worth it in the end.

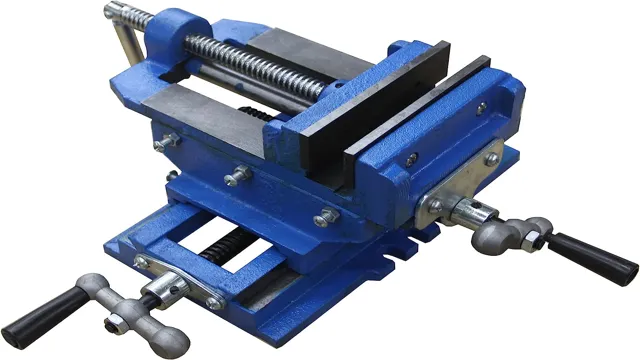

First, make sure you have the right tools and materials, like a drill press vise, drill bits, and safety gear. Once you’ve gathered everything you need, secure the drill press to your workbench. Next, you should adjust the table to the right height and angle for your project, and install the drill bit.

This process can take a little bit of trial and error, but with practice, it will become second nature. Finally, turn the drill press on and start drilling. With a little bit of patience and practice, you’ll be able to create precise holes in no time.

Assembly and Installation

Setting up a bench drill press can be a daunting task for beginners, but it doesn’t have to be. First, ensure that you have all the necessary tools, including a wrench, socket set, and screwdrivers. Next, find a suitable location for your drill press with enough clearance around it for comfortable operation.

Assembly may differ between brands, so refer to your specific manual for guidance. Typically, you will need to attach the column to the base, secure the head to the column, and attach the motor. Once assembled, level the base and adjust the height of the table to your desired position.

Remember to always wear safety gear when operating any machinery, including eye and ear protection. By following these simple steps, you can confidently set up your bench drill press and begin your woodworking projects in no time.

Adjusting the Table Height and Angle

When it comes to setting up your bench drill press, one important aspect to consider is adjusting the table height and angle. This is crucial in ensuring the accuracy and precision of your drilling. Most bench drill presses come with an adjustable table that can be raised or lowered to accommodate various workpieces and drilling depths.

To adjust the height, simply loosen the locking bolts and move the table up or down to your desired height. Additionally, you can also adjust the table angle to make angled drilling easier. Most bench drill presses have a crank or handle that can be used to tilt the table to your desired angle.

Once you have adjusted the table to your desired height and angle, be sure to tighten the locking bolts to keep it securely in place. By taking the time to properly adjust your table, you can ensure that your bench drill press is set up for success.

Using the Bench Drill Press

If you’re wondering how a bench drill press works, it’s quite simple. A bench drill press operates by rotating a drill bit at high speeds to make precision holes in various materials. It features a base, column, table, and head that hold the drill bit and allow for adjustments based on the size of the material being drilled.

The user can adjust the speed of the drilling motion and set the depth of the hole they need to make. The bench drill press is particularly useful for DIY projects where precision drilling is required, such as drilling holes for bolts or creating intricate designs on wood or metal. With the right accessories, it can also be used for sanding, carving, and grinding tasks.

Overall, a bench drill press is an essential tool for any woodworker, metalworker, or DIY enthusiast looking to make accurate and professional-looking holes in their projects.

Selecting the Right Drill Bit

When using a bench drill press, it’s essential to select the right drill bit for the job. Choosing the correct bit not only ensures accuracy but also improves safety by reducing the risk of injuries or damage to the machine. The most common types of drill bits for wood and metal include twist, brad point, spade, and hole saw bits.

For masonry work, carbide-tipped bits are the best choice. Factors to consider when selecting a drill bit include the material being drilled, the size and depth of the hole, and the type of drill press being used. It’s important to remember that each type of drill bit has unique characteristics, and using the wrong one can yield unsatisfactory results.

In summary, the right drill bit can make all the difference when using a bench drill press, and taking the time to select the appropriate one for the task at hand is a crucial step in achieving successful results.

Securing the Workpiece

When working with a bench drill press, securing the workpiece is an essential safety measure. One way to do this is by using clamps or a vise to lock the piece into place. This prevents it from slipping or rotating while drilling and ensures the holes are drilled accurately.

It’s also important to ensure the workpiece is sitting squarely on the drill press table and is at the proper height to avoid the bit from catching or creating a dangerous kickback. Taking the time to properly secure the workpiece will not only keep you safe but will also improve the overall quality of your project. So, before you hit that start button, make sure your workpiece is locked in and ready for drilling.

Don’t cut corners when it comes to safety!

Drilling the Hole

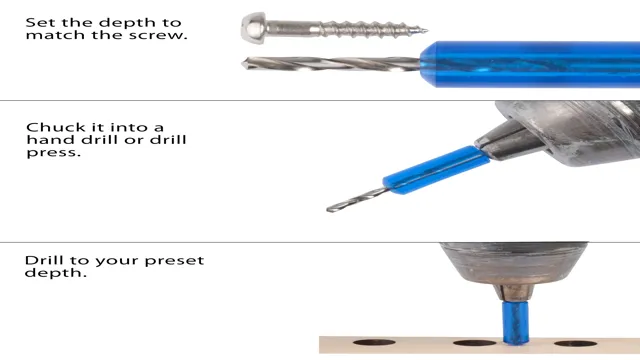

If you need to drill precise and accurate holes in your workpiece, using a bench drill press is the way to go. A bench drill press provides a stable platform for drilling compared to handheld drills, and with its adjustable table and drill bit, you can easily adjust the depth and angle of the drill. To start drilling, ensure that your workpiece is firmly clamped in place, and adjust the table to the desired height and angle.

Then, adjust your drill bit to the desired depth by moving the quill or spindle up or down. Next, line up your drill bit with the spot where you want to drill your hole and turn on the drill press. Use a steady, even pace to drill through your workpiece, and do not force the drill bit or allow it to overheat.

And there you go, you have drilled a precise hole in your workpiece with the help of a bench drill press.

Safety Precautions and Maintenance

If you’re wondering how a bench drill press works, it’s a relatively simple process that’s incredibly useful for precision drilling. Bench drill presses work by using an electric motor to rotate a column that holds a drill bit. The motor provides the power to drive the bit down into the material being drilled.

The column can be adjusted up and down, allowing the drill bit to be set to the desired depth. Bench drill presses are commonly used in woodworking, metalworking, and other industrial applications thanks to their ability to drill holes with greater accuracy and consistency than handheld power drills. However, it’s important to follow safety precautions when using a bench drill press.

Make sure to wear eye protection and keep loose clothing, jewelry, and long hair away from moving parts. Additionally, regularly maintaining your bench drill press by keeping it clean, lubricating moving parts, and checking for damage can help ensure it continues to work properly.

Wearing Protective Equipment

When it comes to wearing protective equipment, the most important thing is to ensure that the equipment is in good condition and properly maintained. This means checking it regularly for signs of wear and tear, as well as cleaning it after each use to prevent the spread of germs. It’s also important to make sure that the equipment is fitted properly, as ill-fitting equipment can be uncomfortable and may not offer the level of protection that is needed.

When choosing protective equipment, it’s important to consider the specific hazards that you may encounter, and to choose equipment that is designed to protect against those hazards. For example, if you are working with chemicals, you will need to wear gloves and protective eyewear that are specifically designed to protect against chemical exposure. By taking the time to select the right protective equipment and maintaining it properly, you can help to ensure that you are able to work safely and avoid accidents and injuries.

Maintaining the Drill Press

Maintaining a drill press is essential for ensuring its longevity and safe usage. When using a drill press, it’s crucial to adhere to safety precautions to prevent accidents. Always wear protective gear such as gloves, goggles, and earplugs.

Keep the drill press clean and free of obstructions by wiping down the surfaces with a soft cloth and removing any debris that may have accumulated. Lubricate the moving parts with oil or grease regularly, especially the chuck and the arbor, to prevent rust and ensure that they move smoothly. Check the belt tension and replace the belt if it’s worn or damaged.

Keep the drill bits sharp and replace them as soon as they become dull to prevent accidents and ensure that the drill press operates effectively. By following these maintenance tips and adhering to safety precautions, you can maintain your drill press’s performance and ensure safe usage.

Troubleshooting Common Issues

When it comes to troubleshooting common issues with your equipment or machinery, it is essential to prioritize safety precautions and maintenance. Regularly checking for loose screws, worn out parts, and damaged wires can prevent accidents from happening in the workplace and prolong the lifespan of your equipment. It is also crucial to ensure that you have the required safety gear, such as gloves, goggles, and helmets, before starting any repairs or maintenance work.

Ignoring these safety measures can result in injury or even fatalities. In addition, maintaining your equipment according to the manufacturer’s guidelines can save you time and money in the long run. The keyword “safety precautions” is vital when it comes to ensuring the well-being of both you and your equipment.

By prioritizing safety and maintenance, you can minimize the risks and maximize the benefits of running your business effectively and efficiently.

Conclusion

In conclusion, a bench drill press is a machine that is both simple and sophisticated in its operation. With the help of a motor, a drill chuck, and a series of gears and pulleys, this device can bore holes into a wide range of materials with precision and ease. Think of it as the modern-day Sherlock Holmes of the workshop, always ready to solve any drilling mystery that comes its way.

So if you want to give your drilling skills a boost, a bench drill press is the ultimate tool to have in your arsenal. It’s like having a genius detective on standby, ready to solve even the toughest drilling cases in no time flat!”

FAQs

What is a bench drill press and how does it differ from a hand drill?

A bench drill press is a stationary drilling tool that is secured to a workbench or mount. Unlike a hand drill, it provides greater accuracy, control, and power to drill holes on a variety of materials using a range of drill bits.

What are the main components of a bench drill press?

The main components of a bench drill press include the base, column, table, spindle, chuck or collet, drill bit, motor, belts, and pulleys.

How do you set up a bench drill press for drilling?

To set up a bench drill press, start by adjusting the height of the table to the desired level, ensuring it is secured to the column. Next, select the appropriate drill bit for your project and insert it into the spindle, securing it with the chuck or collet. Adjust the drilling depth and speed as needed, and align the material to be drilled with the bit. Finally, turn on the machine and apply pressure to the drill bit to begin drilling.

What safety precautions should you take when using a bench drill press?

To ensure safety when using a bench drill press, always wear protective gear such as gloves, goggles, and earplugs. Do not wear loose clothing or jewelry that could get caught in the machine. Keep your hands away from the drilling area and use a clamp or vise to hold the material being drilled. Turn off the machine when adjusting the bit or making any changes to the setup.

How can you maintain and prolong the lifespan of a bench drill press?

To maintain and prolong the lifespan of a bench drill press, keep it clean and free of debris or dust. Lubricate the moving parts and components regularly. Ensure that the belts are correctly tensioned and not worn out. Replace any dull or damaged drill bits and store all components in a dry and secure location when not in use.

What are some common projects that can be done using a bench drill press?

Some common projects that can be done using a bench drill press include drilling holes in metal, wood, and plastics, sanding, polishing, and tapping threads. It can also be used for mortising, counterboring, and reaming.

When should you consider using a bench drill press instead of a hand drill?

You should consider using a bench drill press when precise and accurate drilling is required, or when drilling larger holes or thicker materials with ease. A bench drill press is also useful for repetitive drilling tasks, where the hands may become fatigued when using a hand drill.