Can You Use a Bench Grinder as a Buffer? Pros, Cons and Alternatives Explained.

Whether you’re a professional metalworker or a DIY enthusiast, a bench grinder is an essential tool that can help you save time and effort when it comes to sharpening, grinding, or polishing your metalwork. But what if you don’t have a buffer for smoothing out your edges or removing blemishes? Can you use your bench grinder as a buffer? The answer is yes! With a few adjustments and the right accessories, you can easily turn your bench grinder into a buffer and achieve that professional finish you’re looking for. In this blog post, we’ll show you how to use a bench grinder as a buffer, what kind of buffing wheels you need, and some tips to get the best results.

Let’s get started!

Understanding the Differences Between a Bench Grinder and a Buffer

If you’re wondering whether you can use a bench grinder as a buffer, the answer is no – and vice versa. Bench grinders and buffers serve different purposes, even though they may look similar. A bench grinder is designed to sharpen and smooth rough material whereas a buffer is designed to bring a high-gloss finish to a smooth surface.

In terms of functionality, a bench grinder uses coarse abrasives that remove material quickly, while buffers use softer abrasives to achieve a polished finish. Attempting to use a bench grinder as a buffer would result in an uneven finish due to the roughness of the abrasives. Similarly, using a buffer on rough material would do little to smooth it out.

It is essential to choose the right tool for the job to ensure that it performs optimally and safely. So be sure to invest in both tools to achieve the best results in your projects.

Grinding vs. Buffing

When it comes to metalworking, it’s important to understand the differences between a bench grinder and a buffer. While both tools are used to smooth and shape metal, they have distinct uses. A bench grinder uses a coarse grinding wheel to remove material quickly, while a buffer uses a soft polishing wheel to create a smooth finish.

It’s important to choose the right tool for the job, as using a buffer on material that needs to be removed quickly can cause damage. Just like using a toothbrush to paint a wall wouldn’t be effective, using the wrong tool in metalworking can lead to subpar results. So whether you need to grind away rust and rough edges or create a mirror-smooth finish, make sure you choose the right tool for the job.

Speed and Wheel Size Differences

When it comes to grinding and polishing tools, two of the most commonly used are bench grinders and buffers. At first glance, these tools may seem interchangeable, but they actually have some notable differences. The main difference between the two lies in their speed and wheel size.

Bench grinders typically have larger wheels that rotate at much higher speeds than buffers. This makes them highly effective at removing large amounts of material quickly and is ideal for tasks like sharpening blades or reshaping metal. Buffers, on the other hand, have smaller wheels that rotate at slower speeds, making them better suited for polishing and finishing tasks.

They can help bring a high gloss finish to metals or other surfaces. Understanding these differences is important when selecting the right tool for your project, as using a bench grinder on a polishing task can damage the material or leave it too rough, while a buffer may not have the power needed for grinding tasks. Choose your tool based on the task at hand and let it do the job it was designed for.

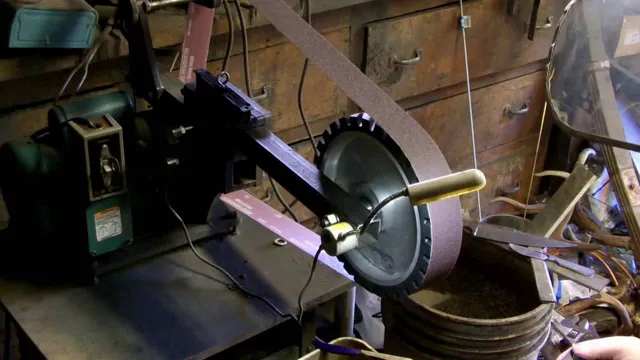

Using a Bench Grinder as a Buffer

If you’re wondering whether you can use a bench grinder as a buffer, the answer is yes, but you’ll need a few things. To start, you’ll need a buffing wheel, which is typically softer than a grinding wheel. You’ll also need buffing compound, which helps smooth and polish the surface.

When using a bench grinder as a buffer, you want to make sure there isn’t any residual grit on the wheel. To do this, use a wire brush to clean the wheel before attaching the buffing wheel. Once everything is set up, turn the grinder on and apply the buffing compound to the wheel.

Move whatever object you are polishing across the spinning wheel steadily, being careful not to apply too much pressure or spend too long in one spot. Remember to wear eye protection, and don’t forget to clean the buffing wheel thoroughly after each use. With a little practice, you’ll be able to achieve a nice shine on any metal surface using your bench grinder as a buffer.

Installation of Buffing Wheels

If you are looking to buff your metal objects at home, you may be wondering if a bench grinder can double as a buffer. The answer is yes, it can! However, the key is to have the right buffing wheel installed on your bench grinder. The first step is to remove the grinding wheel from your bench grinder and replace it with a buffing wheel that is specifically designed for metal polishing.

It is important to make sure the buffing wheel is properly centered and secured before starting to use it. Once you have the buffing wheel mounted, you can start buffing your metal objects and achieving a smooth, polished finish. Remember to always wear safety gear, such as gloves and eye protection, and to follow proper buffing techniques to avoid accidents or damage to your metal objects.

By following these tips, you can transform your bench grinder into a reliable buffer and achieve professional-level results from the comfort of your own home.

Bench Grinder Modifications for Buffing

Have you ever considered using your bench grinder as a buffer? With a few modifications, you can easily transform your grinder into a versatile tool for buffing and polishing a wide variety of surfaces. One of the most important modifications you can make is to add a buffing wheel with a high-quality buffing compound. This will allow you to achieve a smooth finish on metal, wood, plastic, and other materials.

Additionally, you may want to consider swapping out the standard grinding wheels for softer, more flexible ones to reduce the risk of scratching or damaging your workpiece. With a bit of practice and experimentation, you can turn your bench grinder into a valuable addition to your workshop arsenal. So why not give it a try and see what kind of results you can achieve?

Safety Precautions

When using a bench grinder as a buffer, there are important safety precautions that need to be taken to avoid accidents. Firstly, make sure to wear eye and ear protection as the grinder can create sparks and noise that can be harmful. Additionally, do not wear loose clothing or jewelry that can get caught in the machine.

To prevent the material from flying off the grinder, always keep a secure grip on it and use a clamp if needed. Another crucial safety tip is to avoid using the grinder near flammable or combustible materials. Taking these precautions can ensure that you can effectively use your bench grinder as a buffer without causing harm to yourself or others.

Benefits and Drawbacks of Using a Bench Grinder as a Buffer

Yes, you can use a bench grinder as a buffer, however, there are benefits and drawbacks to this method. One of the benefits is cost-effectiveness, as a bench grinder is typically less expensive than a buffer. Additionally, a bench grinder can often be used to perform other tasks, such as sharpening tools, making it a versatile tool to have in your workshop.

On the other hand, there are some drawbacks to using a bench grinder as a buffer. One major issue is the potential for uneven results, as the grinder’s high-speed rotation can cause areas of the surface to be buffed more than others. Another downside is the lack of control, as a bench grinder typically has a less precise speed adjustment than a dedicated buffer, which can make it more challenging to achieve the desired finish.

Ultimately, whether to use a bench grinder as a buffer will depend on the project’s specifics and the level of precision required.

Cost Savings

If you’re looking to save some money on polishing equipment, using a bench grinder as a buffer seems like a no-brainer. While bench grinders are typically used for grinding down metal, they can also be outfitted with a buffing wheel to achieve a smooth and shiny finish. The obvious benefit here is cost savings, as bench grinders with buffing capabilities are much cheaper than separate buffer machines.

However, there are also drawbacks to consider. For one, bench grinders tend to spin at higher speeds which can lead to overheating and damage to certain materials. Additionally, bench grinders don’t offer the same level of precision and control that dedicated buffer machines do, which can be problematic for delicate or intricate polishing jobs.

At the end of the day, using a bench grinder as a buffer can be a viable cost-saving option for some applications, but it’s important to weigh the benefits and drawbacks before making a decision.

Less Precision

Using a bench grinder as a buffer can have its benefits, but it also comes with some drawbacks. One of the main drawbacks is less precision. Bench grinders are designed to remove material quickly and aggressively, which means they are not the best option for finer finishing tasks.

Buffing requires a high level of precision, and a bench grinder may not be able to provide the level of accuracy you need. In addition, bench grinders generate a lot of heat, which can cause damage to delicate materials or cause the wax or compound to melt. However, if you are working with larger or more robust materials, a bench grinder can be a great tool to quickly remove blemishes or smooth out rough edges.

Just be sure to use the appropriate type of buffing wheel and adjust the speed accordingly to avoid damage or accidents.

Conclusion

In conclusion, while it may seem like a good idea to try and interchange the functions of a bench grinder and a buffer, the reality is that they are fundamentally different tools. Just like how you wouldn’t try to drive a nail in with a screwdriver, you shouldn’t try to buff out a scratch with a bench grinder. So, to answer the question “Can you use a bench grinder as a buffer?” – technically, yes, but it’s not recommended.

Save yourself the frustration and invest in the proper tool for the job.”

FAQs

What is the difference between a bench grinder and a buffer?

A bench grinder is primarily used for sharpening and grinding metal while a buffer is used for polishing and buffing surfaces.

Can you convert a bench grinder into a buffer?

It is possible to convert a bench grinder into a buffer by replacing the grinding wheel with a buffing wheel and installing appropriate buffing compounds.

What are the benefits of using a buffer?

Buffing can create a smoother and shinier surface finish on metal, plastic, and other materials.

What types of materials can be buffed using a buffer?

A buffer can be used to buff various materials such as metal, plastic, wood, and even painted surfaces.

How do you use a buffer?

To use a buffer, apply a small amount of buffing compound onto the surface of the buffing wheel and turn on the buffer. Use the rotating wheel to buff the surface evenly.

What safety precautions should you follow when using a bench grinder as a buffer?

When using a bench grinder as a buffer, wear safety glasses, gloves, and a face shield to protect yourself from flying debris. Additionally, make sure the buffing wheel is in good condition and properly secured to the bench grinder.

Can you buff aluminum using a bench grinder as a buffer?

Yes, you can buff aluminum using a bench grinder as a buffer. However, it is important to use a buffing wheel that is designed for use on aluminum and the appropriate buffing compounds for the job.