If you’ve been wondering whether PEX can safely and effectively be used for compressed air, you’re certainly not alone. Many people underestimate the importance of choosing the right materials for different applications, including compressed air systems. However, taking shortcuts or using the wrong materials can have serious consequences, such as leaks, system failures, and even injuries.

So, can PEX be used for compressed air? The answer, unfortunately, is not that simple. In this blog, we’ll explore some important aspects of using PEX for compressed air and help you make an informed decision.

Understanding PEX

PEX, or cross-linked polyethylene, is a popular material used for plumbing and heating systems. However, can PEX be used for compressed air? The short answer is no. PEX is not rated for use with compressed air systems and could potentially burst under pressure, leading to serious safety concerns.

It’s important to always check the manufacturer’s specifications and ratings for any piping material before using it in a compressed air application. In general, materials like copper, steel, and aluminum are more commonly used for compressed air systems due to their high durability and strength. So while PEX may be a great choice for your plumbing needs, it’s important to choose the right material for your compressed air system to ensure the safety and efficiency of your equipment.

What is PEX?

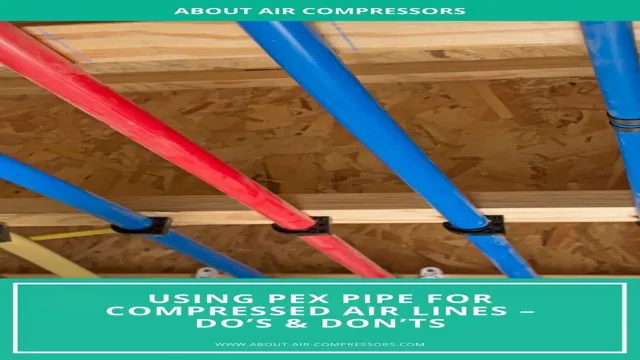

PEX, an acronym for cross-linked polyethylene, is a type of plastic piping used in plumbing and heating systems. It has become increasingly popular due to its flexibility, durability, and ease of installation. PEX is known for its ability to expand and contract with temperature changes, which helps prevent burst pipes in extreme weather conditions.

Moreover, it is corrosion-resistant, making it suitable for use in areas with high mineral content. Another advantage of PEX is its affordability, making it an ideal option for those looking to save on material costs. Overall, PEX offers numerous advantages over traditional plumbing materials and is becoming the preferred choice for many homeowners and contractors alike.

Types of PEX Tubing

PEX tubing is an excellent choice for plumbing projects due to its flexibility, durability, and resistance to high temperatures. However, different types of PEX tubing are available on the market, and it is essential to understand them before picking the one that best suits your needs. The most commonly used types of PEX tubing are PEX-a, PEX-b, and PEX-c.

PEX-a is the most flexible and durable of the three but can also be more expensive. PEX-b is a cost-effective option and often used in residential plumbing projects. PEX-c is a sturdy and high-quality option frequently used in commercial applications.

Understanding the differences between these types of PEX tubing can help you make an informed decision when choosing the appropriate tubing for your plumbing project.

Properties of PEX Tubing

PEX tubing is a revolutionary plumbing material that has been gaining popularity in recent years due to its many benefits. It is made from cross-linked polyethylene, which makes it highly flexible and resistant to freeze damage. One of the key properties of PEX tubing is its ability to expand and contract with temperature changes, which reduces the risk of burst pipes.

Its smooth interior also promotes better water flow and reduces the risk of clogs. Additionally, PEX tubing is corrosion and chemical resistant, which improves its longevity. Its ease of installation also makes it popular among plumbers and DIY enthusiasts alike.

Overall, PEX tubing offers a reliable and efficient solution for plumbing needs and is becoming a go-to choice for many homeowners and businesses alike.

Compressed Air Requirements

When it comes to compressed air requirements, using PEX may not be the best option. While PEX piping is known for its flexibility and durability, it is not recommended for compressed air applications due to the risk of bursting under pressure. Compressed air systems require specialized piping that can withstand high pressures and provide consistent airflow.

PEX, on the other hand, is designed for low-pressure systems such as plumbing and radiant heating. It’s important to choose the right piping for the job to ensure safety and efficiency. So, can PEX be used for compressed air? The short answer is no.

It’s best to use piping materials specifically designed for compressed air systems such as copper, steel, or aluminum.

Pressure and Temperature Requirements for Compressed Air Systems

Compressed air systems are essential in many industries and require proper pressure and temperature requirements to function efficiently. The pressure requirements for compressed air systems will depend on the specific application and equipment being used. For example, some equipment requires high-pressure levels, while others only need moderate levels.

Generally, compressed air systems operate between 70 to 100 psi, but some specialty applications might require much higher or lower psi levels. It’s important to note that exceeding the maximum psi level can cause severe damage to the system, leading to leaks, ruptures, and other costly situations. When it comes to temperature requirements, most compressed air systems must be kept cool to ensure optimal performance and prevent damage to the equipment.

Higher temperatures can cause moisture and oil build-up in the system, leading to malfunctions and a shorter lifespan. Therefore, it’s essential to monitor both temperature and pressure levels regularly to maintain proper efficiency and prevent costly damages. As always, investing in the right equipment and having proper maintenance and safety protocols in place can help minimize the risk of issues occurring.

Materials Suitable for Compressed Air Systems

When it comes to selecting materials for a compressed air system, there are a few important things to consider. First and foremost, it is essential to choose materials that can withstand the high pressure of the compressed air. Materials that are commonly used for this purpose include steel, copper, and aluminum.

Another important consideration is corrosion resistance. Moisture is often present in compressed air, which can lead to corrosion over time. Materials like stainless steel, plastic, and aluminum are resistant to corrosion and can help extend the life of the compressed air system.

It is also important to consider the material’s compatibility with the substances that will be running through the compressed air system. For example, if the system will be used for transmitting oil or other fluids, materials like nylon or Teflon may be suitable. Ultimately, the choice of materials for a compressed air system will depend on the specific needs and requirements of the system.

By selecting appropriate materials, however, it is possible to ensure that the compressed air system operates safely and effectively for many years to come.

Can PEX be Used for Compressed Air?

If you’re in the market for a compressed air system for your home or workshop, you may have heard that PEX pipes can be a cost-effective solution. However, the question of whether or not PEX tubing can be used for compressed air remains a hot topic of debate among industry professionals and DIY enthusiasts alike. While PEX piping is known for its flexibility and ease of installation, it may not be the best choice for compressed air systems.

This is because PEX pipes can become brittle over time and are more susceptible to bursting or rupturing under pressure. It’s important to consult with a licensed plumber or compressed air expert to determine the right materials for your specific needs and ensure safe installation.

PEX’s Suitability for Compressed Air Systems

PEX piping is becoming increasingly popular in plumbing systems due to its flexibility, ease of installation, and durability. However, when it comes to compressed air systems, PEX pipes might not be the best option. While PEX pipes are generally able to handle the pressure and flow rate of compressed air, they are not designed or rated for it.

This means that using PEX pipes for compressed air systems can cause damage, leaks, and even burst pipes, which can lead to safety hazards and costly repairs. It’s important to use piping materials that are specifically designed for compressed air, such as copper or steel, to ensure the safety and reliability of the system. So, although PEX piping is a great option for plumbing systems, it’s not recommended for compressed air systems.

PEX’s Limitations for Compressed Air Systems

PEX pipes have become a popular choice for plumbing systems due to their durability, flexibility, and affordability. However, when it comes to compressed air systems, PEX has certain limitations that make it an unsuitable material. PEX is not designed to withstand high pressure, and when exposed to compressed air, it can cause the pipes to burst or rupture.

Furthermore, the fittings used for PEX pipes may not be suitable for compressed air systems, and can cause leaks or other malfunctions. Therefore, it is vital to use materials specifically designed for compressed air systems, such as copper, aluminum, or steel pipes. By using the right materials, you can ensure the safety and reliability of your compressed air system, and avoid costly and dangerous accidents.

So, next time you’re planning a compressed air system, be sure to choose the right materials for the job!

Alternative Materials for Compressed Air Systems

PEX, also known as cross-linked polyethylene, is a popular alternative material for compressed air systems. While traditionally used for plumbing systems due to its durability and flexibility, PEX has started to gain traction in the world of compressed air as well. One of the biggest advantages of using PEX for compressed air is its ability to handle high pressures, with some types able to withstand up to 200 PSI.

However, it is important to note that not all PEX pipes are suitable for compressed air, and it is essential to check with the manufacturer for the proper type and size of PEX to use. It’s also important to take into consideration the potential for perplexity and burstiness that can occur with compressed air systems, so proper installation and maintenance are crucial. With proper precautions and the right type of PEX, it can be a reliable and cost-effective choice for those looking for an alternative material for their compressed air system.

Conclusion

In conclusion, while PEX piping has many versatile uses, it is not recommended for use with compressed air systems. The high pressure and potential for rapid air expansion can cause PEX to rupture and fail, leading to dangerous situations. So, let’s leave the compressed air to the experts and stick to using PEX for its intended purposes, like plumbing and radiant heating.

Remember, just because something can be used for a certain application doesn’t mean it should be!”

FAQs

1. What is PEX tubing and what are its properties? PEX tubing is a type of flexible plastic piping used in many plumbing applications. It is made of cross-linked polyethylene, which gives it excellent resistance to temperature changes and chemical damage. 2. Is PEX tubing safe for use with drinking water? Yes, PEX tubing is certified for use with drinking water by NSF International and is considered safe for use in plumbing and water supply systems. 3. Can PEX tubing be used for compressed air systems? PEX tubing is not recommended for compressed air systems as it has not been approved for such use and may not be able to withstand the high pressures and temperature changes associated with compressed air. 4. How does PEX tubing compare to traditional copper pipe in terms of installation? PEX tubing is generally easier and faster to install than copper piping, as it requires fewer tools and fittings and can be bent easily to fit around corners and obstacles. 5. What is the maximum temperature that PEX tubing can withstand? PEX tubing can typically handle temperatures up to 200°F, making it suitable for use in hot water systems. However, it is important to consult manufacturer specifications and local building codes for specific installation requirements. 6. Can PEX tubing be used for radiant floor heating systems? Yes, PEX tubing is commonly used for radiant floor heating systems as it can be easily installed under flooring and is compatible with many types of heat transfer fluids. 7. How does the cost of PEX tubing compare to other types of piping? While the cost of PEX tubing varies depending on the application and installation requirements, it is generally less expensive than copper piping and other options. Additionally, the ease of installation can help reduce labor costs.