How to Make a Homemade Car Battery Charger: Step-by-Step Guide

Is your car battery dead and you’re stuck in the middle of nowhere with no access to a charger? Don’t panic! You can make your very own homemade car battery charger with just a few basic tools and materials. This step-by-step guide will walk you through the entire process and help you get back on the road in no time. Not only is it a cost-effective solution, but it’s also environmentally friendly as you’re repurposing old materials.

With a little bit of DIY know-how, you can make a homemade car battery charger that’s just as effective as its store-bought counterparts. Keep reading to learn how!

Introduction

Are you tired of having to replace your car battery charger all the time? Why not try making your own homemade car battery charger? It’s easier than you might think! All you need are a few basic tools and some materials that can be easily sourced online or from your local hardware store. The main component of a car battery charger is a transformer and a rectifier. You can get these components from an old computer power supply or purchase them from an electrical store.

Once you have all the components, you can start building the charger by following some simple wiring diagrams. With a bit of patience and some basic electrical knowledge, you can soon have a working homemade car battery charger for all your charging needs. Not only will this save you money, but it’s also a fun project to undertake.

So, why not give it a try and see the results for yourself?

Why Make Your Own Car Battery Charger?

Making your own car battery charger may seem like an unnecessary task, especially with the abundance of ready-made chargers available in the market. However, understanding the benefits of creating your own charger can change your perspective. For starters, making one is a fun and fulfilling experience, potentially opening doors to other DIY projects.

It is also a cost-effective option that allows you to customize the charger to meet your specific needs and preferences. Moreover, the knowledge gained in creating a charger can come in handy in cases of emergency when a commercial charger is unavailable. Making your own charger allows you to take control of your car’s battery health and improve its longevity.

By engaging in this project, you gain a deeper understanding of car batteries, electricity, and electronics, making it a worthwhile endeavor.

What You Will Need

When it comes to starting a new project or hobby, having the right tools and resources can make all the difference in your success and enjoyment. If you’re considering starting a new blog, there are a few key items you’ll need to get started. Firstly, you’ll need a reliable laptop or computer to use for writing and editing your content.

Additionally, it’s important to have a strong and consistent internet connection, as well as a domain name and web hosting service to create and publish your blog online. Whether you’re an experienced blogger or just starting out, having high-quality images and graphics can add an extra element of professionalism to your blog, so investing in a good camera and editing software can also be beneficial. Ultimately, the success of your blog will depend on the quality and consistency of your content, but having the right tools and resources will help you to achieve your goals and build a successful online presence.

So, let’s dive in and explore what you’ll need to get started on your blogging journey!

Step 1: Assemble Components

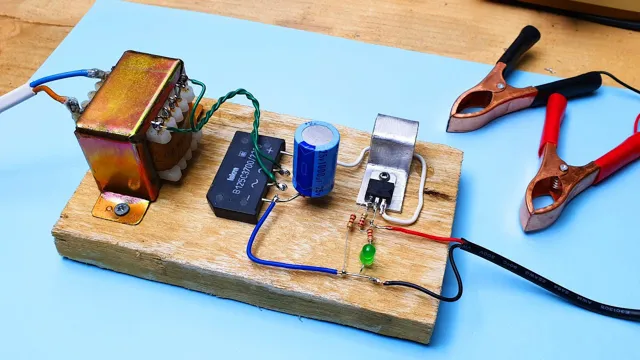

If you’re interested in making a homemade car battery charger, the first step is to assemble the necessary components. You’ll need a transformer, a rectifier, and a filter capacitor. The transformer will convert the voltage from your outlet to a level that is safe for your battery.

The rectifier will ensure that the current flows in only one direction, while the filter capacitor will smooth out any ripples in the current. You’ll also need some wire and a few basic tools, such as pliers and a screwdriver. Assembling the components can be a bit tricky, so it’s important to follow a clear set of instructions that outlines exactly how to connect everything together.

Once you’ve assembled the components, you’ll be well on your way to creating your own homemade car battery charger that can save you money and allow you to customize the charger to suit your specific needs.

Gather Materials

Whether you’re planning to build something for your home, fix a broken item, or create a DIY project, the first step is gathering what you need. Assembling the components or materials is crucial and ensures you won’t be stuck midway without something you need. Depending on the project, materials can vary from small screws to heavy-duty power tools.

Make sure to create a list of everything you need, including the smallest items and their quantity, to avoid any potential problems. Putting some thought into the materials you’ll need can save you time, money, and headaches in the long run. So, let’s get started and gather all the necessary components to complete your project!

Solder Components

When it comes to soldering electronic components, the first step is to assemble the components. This means getting all the necessary components ready and in place for soldering. This usually involves gathering the components required to complete the circuit, such as resistors, capacitors, and diodes, and ensuring that they are of the correct value and orientation.

Once all the components are collected, it is essential to double-check that all the components have been placed in their correct positions, with attention given to their orientation to ensure that they are aligned correctly. This will ensure that there are no issues when soldering the components in place. Overall, taking the time to assemble the components correctly will lead to better results, more reliable circuits, and a smoother soldering experience.

So, let’s get started with assembling our components and prepare everything for successful soldering.

Step 2: Build the Charger

Once you have gathered all the necessary materials, it’s time to start building your homemade car battery charger. First, begin by constructing the housing for your charger using the plastic container. Make sure it’s big enough to fit the transformer, diodes, and capacitors with enough space for air to circulate.

Then, connect the transformer to the AC power source with proper wiring. Next, attach the diodes to the transformer using heat shrink tubing to prevent any short circuits. Connect the diodes together to form a full-wave rectifier and add the capacitors to smooth out any fluctuations in voltage.

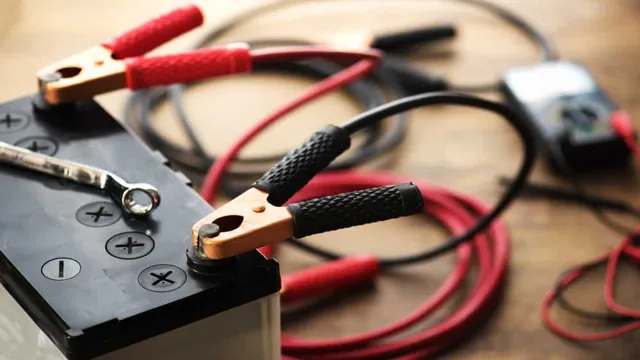

Finally, attach the clamps to the output wires and you’re ready to charge your car battery! Keep an eye on the charging process and monitor the voltage using a multimeter. With this DIY charger, you can save money and feel accomplished in making something practical.

Install Circuit Board

To build the charger for your electronic device, the second step is to install the circuit board. The circuit board is a crucial component that connects all the elements of the charger, such as the transformer, diodes, capacitors, and resistors. To install the circuit board, you need to ensure that the markings on the board match the circuit diagram and the orientation of each component is correct.

You can use a soldering iron to attach the components to the board. Make sure that each connection is secure and any excess solder is removed to prevent short circuits. Once the circuit board is properly installed, carefully inspect it for any signs of damage or disconnected components.

Testing the charger using a multimeter can ensure that the circuit is working correctly and that all electrical parameters are met. Installing the circuit board may seem daunting; however, taking the time to ensure proper installation will ensure that your charger functions correctly and safely.

Attach Transformer

Now that you have your components ready, it’s time to start building the charger. The second step is to attach the transformer. The transformer is a vital component in the charger that helps convert high voltage to low voltage as required by your device.

Before attaching the transformer, make sure you read the instructions carefully to avoid any mishaps. Once you’re ready, start by identifying the primary and secondary wires of the transformer. Be careful not to mix them up as this could lead to electricity mismanagement that could harm your device or even yourself.

After successfully identifying the wires, connect them to the solder pads on the charger board. Make sure each wire is secure, as a loose wire could cause issues within the charger. Using a heat gun, apply heat to the solder pads to melt the solder and fuse the transformer wires to the board.

Be sure to avoid overheating, as this could cause electrical damage. Congratulations, you have now completed step two of building your charger. Your charger is now closer to being ready to power your device.

Connect Capacitors and Diodes

Now that you have gathered all the required components, it’s time to build the charger. The second step is to connect the capacitors and diodes. Capacitors store energy, while diodes allow the current to flow in one direction.

You will need a high voltage capacitor and fast recovery diodes for this purpose. Start by connecting the positive terminal of the capacitor to the anode of the diode, and the negative terminal of the capacitor to the cathode of the diode. Repeat this process for all the capacitors and diodes you have.

The capacitors and diodes are essentially forming a bridge rectifier that will convert AC to DC, ensuring that the battery is properly charged. Ensure all the connections are tight, and the wires are properly soldered. This will prevent any loose connections that may cause a short circuit or fire.

With the capacitors and diodes connected, you can move on to the next step of building the charger. By following these steps, you should be well on your way to building a safe and effective charger that will keep your batteries fully charged.

Add Indicator Lights

Now that we’ve finished testing and building the USB power bank, it’s time to move on to the next step – building the charger. One key aspect of any charger is having an indicator light to let you know when it’s charging and when it’s finished. This is especially important when you’re dealing with something like a power bank that needs to be charged up before use.

So, the next step is to add the indicator lights. The easiest way to do this is to use LED lights, which are cheap, easy to find, and come in a variety of sizes and colors. You’ll need to attach them to the charger circuit using a resistor or other appropriate components to ensure they don’t burn out.

Once attached, the LEDs will light up when the charger is plugged in and charging, and turn off once the battery is fully charged. It’s a small but important addition that will make your charger much more user-friendly.

Step 3: Test Your Charger

Once you’ve assembled your homemade car battery charger, it’s essential to test it to ensure it works correctly and safely. First, plug the charger into an electrical outlet and use a voltmeter to check the voltage. Make sure the voltage matches the specifications for your chosen battery type.

Next, connect the charger to the battery, paying careful attention to the polarity. If you’ve wired everything correctly, the charger should start working right away. Keep an eye on the BCI and charge rate meters to ensure everything is progressing as it should.

When the battery is fully charged, the charger should shut off automatically. Don’t forget to test your charger regularly to ensure it remains in good working order. With this kind of charger, you can easily keep your car battery topped up and ready to go whenever you need it!

Connect Battery

Now that you’ve connected your battery, it’s time to test your charger. This step is crucial to ensure that everything is working correctly before you hit the road. Start by plugging in the charger and turning it on.

Check that the LED light on the charger is indicating that it is charging the battery. If the light is not on, try unplugging and plugging the charger back in or checking the power outlet. It’s also a good idea to check the voltage of the battery to confirm that the charger is providing the correct level of power.

This step will help prevent any potential issues or breakdowns on the road. So take your time and make sure everything is in good working order before you head out.

Check Voltage and Amperage

When it comes to testing your charger, checking the voltage and amperage is crucial. This step ensures that your charger is functioning correctly and providing the necessary power to your device. Voltage is the measure of electric potential between two points, and amperage is the measure of electric current flowing through those points.

It’s important to note that the voltage and amperage requirements vary for different devices. To check the voltage and amperage of your charger, you will need a multimeter, which can measure both. Simply set your multimeter to the DC voltage and amperage settings and connect the probes to your charger’s positive and negative terminals.

The reading you get should match the voltage and amperage requirements of your device, so make sure to double-check those specifications. If the readings don’t match, it’s likely that your charger is faulty and may need to be replaced. By testing your charger’s voltage and amperage, you can ensure that your device is getting the right amount of power it needs to function correctly.

Conclusion

In conclusion, creating your own homemade car battery charger can save you money and provide a satisfying DIY project. With some basic tools and a bit of electrical know-how, you can transform a simple shopping cart into a powerful charging machine. Just be sure to use caution and follow safety guidelines to avoid any shocks or malfunctions.

So charge up your creativity and get ready to hit the road with a battery that’s always ready to go!”

Benefits and Risks of Homemade Chargers

Now that you’ve built your homemade charger, it’s important to test it before using it to charge any devices. Testing your charger is a crucial step in ensuring that it’s safe to use and won’t damage any of your electronics. A simple way to test your charger is by using a multimeter to measure the voltage and current of your charger.

If your charger is not putting out the correct voltage or current, it may be dangerous to use. Additionally, it’s important to test your charger on multiple devices to ensure that it works properly with different types of electronics. By taking the time to test your charger, you can avoid potential safety hazards and ensure that your homemade charger is a reliable and effective option for charging your devices.

Final Thoughts

Final Thoughts: Step 3 – Test Your Charger After repairing or replacing your charger, it’s crucial to test it to ensure it is functioning correctly. Start by plugging it into your device and checking that it is charging. If not, try using a different outlet or cable to see if the problem is with those instead.

It’s also helpful to use a multimeter to verify that the voltage output is within the range specified by the manufacturer. Remember, a faulty charger can lead to battery damage, which is both expensive and potentially hazardous. So, taking the extra time to test your charger can save you from bigger problems down the road.

Overall, it’s important to regularly check your chargers and replace them if they show signs of wear or malfunction. By doing so, you can extend the lifespan of your devices and keep them running smoothly.

FAQs

What are the materials required to make a homemade car battery charger?

To make a homemade car battery charger, you will need a transformer, a rectifier, a capacitor, an ammeter, and some cables.

How do you build a simple car battery charger at home?

To build a simple car battery charger at home, first connect the transformer to the AC power source and the rectifier. Then, connect the ammeter in series to the rectifier output and the battery. Finally, connect the capacitor in parallel to the rectifier output and the battery.

How long does it take to charge a car battery with a homemade charger?

The time it takes to charge a car battery with a homemade charger depends on the capacity of the battery and the output of the charger. On average, it can take between 6 to 12 hours to fully charge a car battery.

Can a homemade car battery charger damage my car battery?

Yes, a homemade car battery charger can damage your car battery if it is not built properly or does not have the correct output voltage. It is important to follow proper guidelines and use appropriate materials when building a homemade charger.

Is it safe to use a homemade car battery charger?

When built properly and used correctly, a homemade car battery charger can be safe to use. However, it is important to exercise caution and follow proper safety guidelines when working with electricity.

Can a homemade car battery charger be used on other types of batteries?

Yes, a homemade car battery charger can be used on other types of batteries as long as the output voltage matches the requirements of the specific battery. It is important to consult the battery manufacturer’s guidelines before attempting to charge the battery.

Can a homemade car battery charger charge a completely dead car battery?

Yes, a homemade car battery charger can charge a completely dead car battery, but it may take longer and require more effort. It is important to monitor the charging process and ensure that the battery does not overcharge, which can also damage the battery.